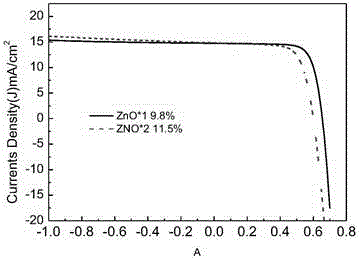

A double-layer structure window layer applied to high-efficiency thin-film photovoltaic cells

A double-layer structure and window layer technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of increasing photogenerated electron-hole recombination, low conversion efficiency, reducing device open circuit voltage and fill factor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

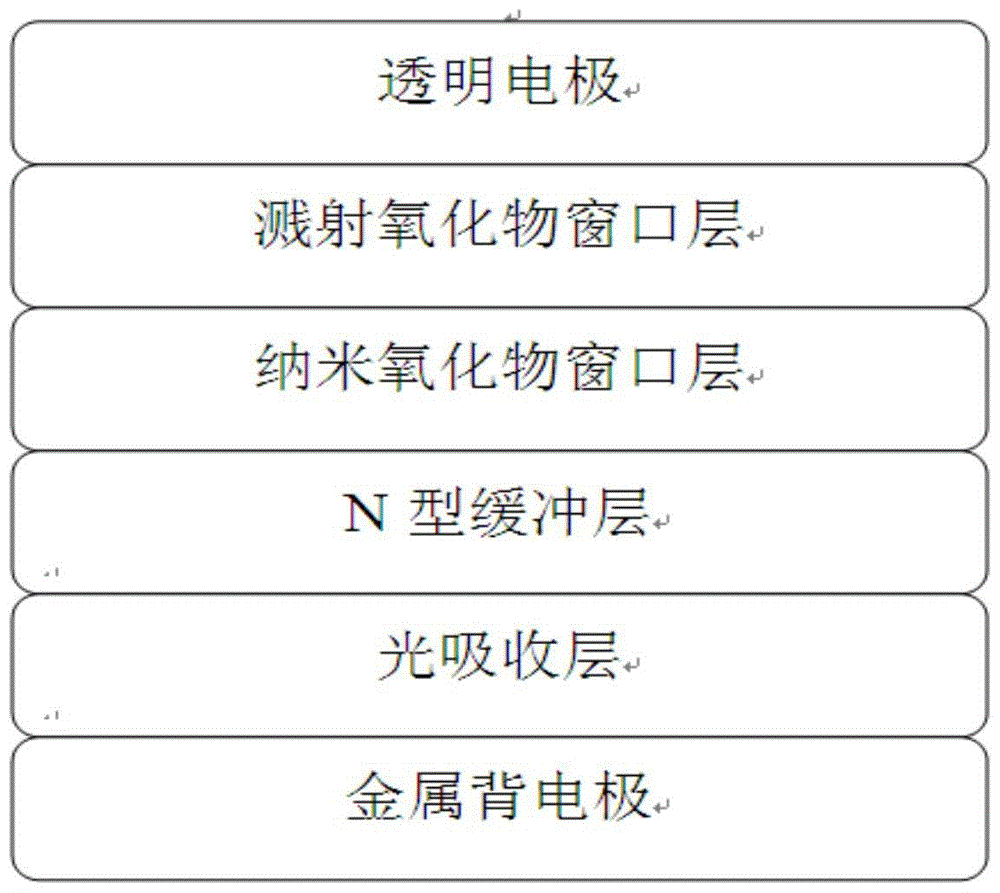

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, it is a structural schematic diagram of a copper indium gallium selenide photovoltaic device using a double-layer structure window layer. The device comprises: a metal back electrode 1; a copper indium gallium selenide light absorbing layer 2; an N-type buffer layer 3; a double-layer structure window layer 4, the window layer includes a nano-zinc oxide layer prepared by a solution method and a high-density zinc oxide layer prepared by a vacuum sputtering method. a dense zinc oxide layer; and a transparent conductive substrate 5 .

[0021] The metal back electrode 1 is generally aluminum, but not limited thereto, and also includes gold, silver, copper, titanium, chromium, molybdenum and other metals. Above the metal electrode 1 is a light absorbing layer 2 with a thickness between 0.1-10um, made of lead sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com