Slash pine needle extract and use thereof

A technology of pine needle extract and slash pine, applied in application, biocide, animal repellent, etc., can solve problems such as residue, little effect, and large environmental pollution, achieve excellent inhibition and killing of moss, and improve water quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

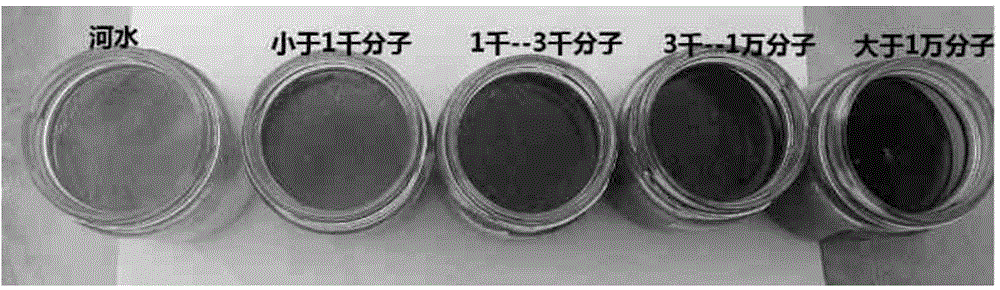

[0023] Example 1 Inhibitory effect of slash pine needle extracts of different molecular weights on moss.

[0024] (1) Prepare stock solution

[0025] Take fresh slash pine needles and cut them into 2-3 cm long with scissors, then crush them with a high-speed pulverizer, take 100 g of crushed pine needles, add tap water at a ratio of 1:10 for extraction for 24 hours, then filter with nylon gauze to remove the residue, and use A vacuum pump is used for suction filtration to obtain a sample as a stock solution.

[0026] (2) 1KD molecular weight cut-off dialysis

[0027] Use a 1KD molecular weight cut-off dialysis bag to take 200mL of the tap water extract (stock solution) of Pinus sclerosus (to prevent the concentration of the dialysis fluid from being too low) and place it in a 1000mL beaker for dialysis. After dialysis for 12 hours, take out the dialysis fluid (components less than 1KD) and place it at 4°C Store in the refrigerator. Then add 500mL of distilled water to conti...

Embodiment 2

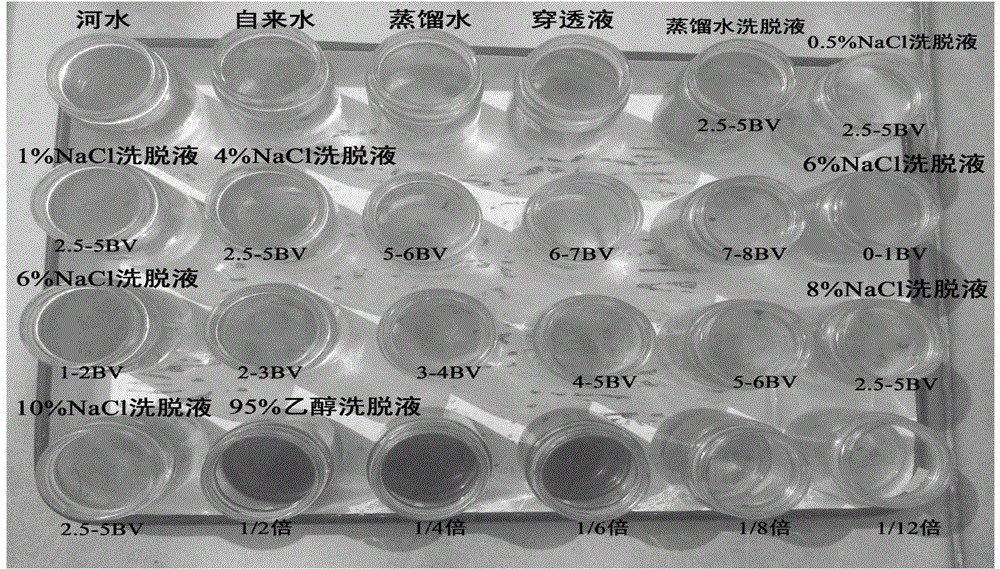

[0035] Example 2 Inhibitory effect of pine needle extracts eluted with different concentrations of NaCl on moss.

[0036] (1) Pretreatment of resin

[0037] Take a 250mL ion exchange column packed with AB-8 resin, fill the column with about 2 / 3 volume of the resin, then add ethanol equivalent to 0.4-0.5 times the volume of the loaded resin into the adsorption column, and soak the resin for 24 hours. After washing the ethanol with deionized water, soak it with 3% hydrochloric acid for 2 hours, wash the resin with deionized water until it is neutral; then soak it with 3% sodium hydroxide solution for 2 hours, wash it with deionized water until it is neutral.

[0038] (2) Preparation of penetration solution

[0039] Take fresh slash pine needles and cut them into 2-3 cm long with scissors, then crush them with a high-speed pulverizer, take 100 g of crushed pine needles, add tap water at a ratio of 1:10 for extraction for 24 hours, then filter with nylon gauze to remove the resid...

Embodiment 3

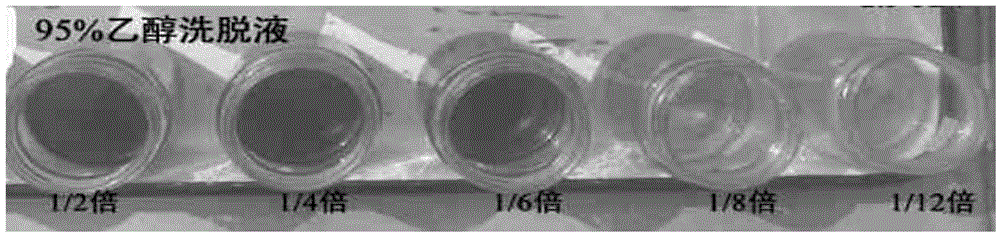

[0061] Example 3 Inhibitory effect of pine needle extracts eluted with different concentrations of ethanol on moss.

[0062] (1) Pretreatment of resin

[0063] Take a 250mL ion exchange column packed with AB-8 resin, fill the column with about 2 / 3 volume of the resin, then add ethanol equivalent to 0.4-0.5 times the volume of the filled resin into the adsorption column, and soak the resin for 24 hours. After washing the ethanol with deionized water, soak it with 3% hydrochloric acid for 2 hours, wash the resin with deionized water until it is neutral; then soak it with 3% sodium hydroxide solution for 2 hours, wash it with deionized water until it is neutral.

[0064] (2) Preparation of penetration solution

[0065] Take fresh slash pine needles and cut them into 2-3 cm long with scissors, then crush them with a high-speed pulverizer, take 100 g of crushed pine needles, add tap water at a ratio of 1:10 for extraction for 24 hours, then filter with nylon gauze to remove the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com