Coalbed methane waste water treatment method

A treatment method and technology for coalbed methane, which are applied in the field of coalbed methane wastewater treatment, can solve the problems of large area of treatment facilities, excessive organic matter in wastewater, and excessive heavy metal ions, and achieve low maintenance requirements, high feasibility, and rapid response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

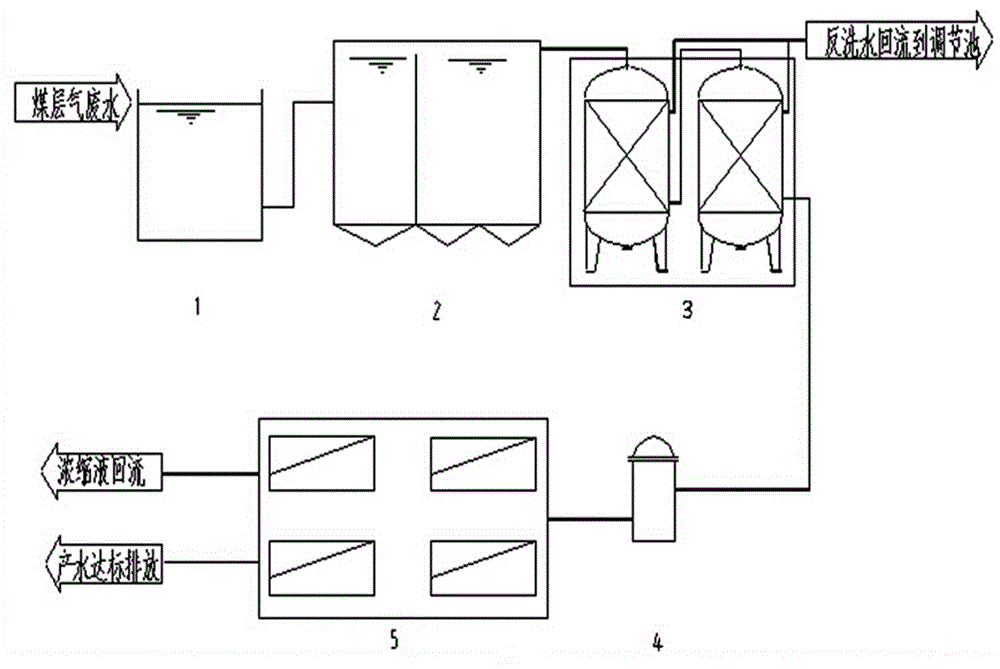

[0048] Describe an embodiment below in conjunction with accompanying drawing, the present invention is described in detail.

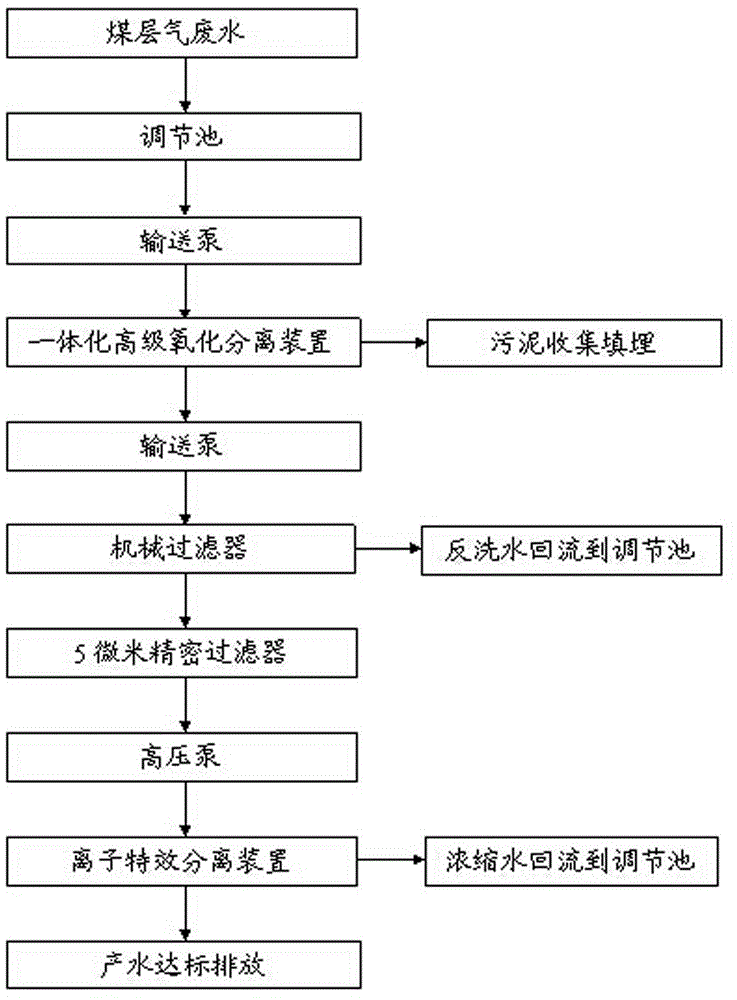

[0049] Example One of coalbed methane wastewater treatment methods is carried out according to the following steps:

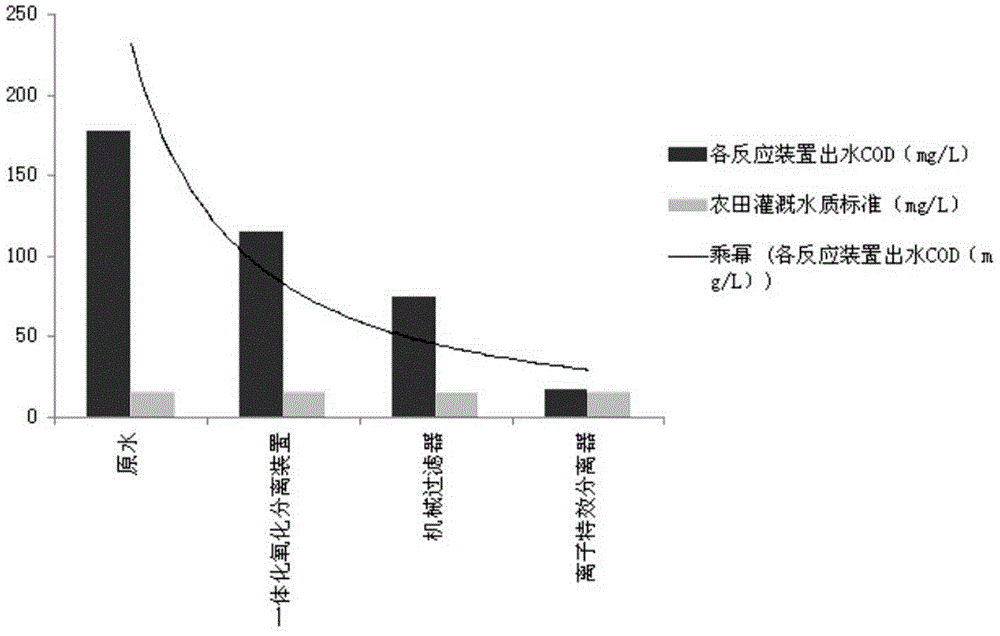

[0050] This embodiment is to use the present invention to carry out the coalbed methane wastewater treatment test at a certain coalbed methane site, the treatment capacity is 5t / d, the water outlet of each equipment in the process is analyzed for water quality, and the local coalbed methane wastewater is analyzed for water quality, according to " "Farmland Irrigation Water Quality Standard" determines that the excessive substances are COD, total dissolved solids and fluoride, and compares and analyzes the produced water with the "Farmland Irrigation Water Quality Standard" to verify the feasibility of the invention.

[0051] Step 1: Collect the coalbed methane wastewater into the regulating tank 1 for homogenization, and monitor th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com