Method and system for co-processing waste incineration fly ash by using rotary hearth furnace

A technology for waste incineration fly ash and co-processing, which is applied in the fields of metallurgy and energy, can solve the problems of limited waste fly ash composition, failure to realize resource utilization, and impact on the quality of cement clinker, and achieves technological innovation and strong application. , to achieve the effect of harmless treatment and resource utilization, social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

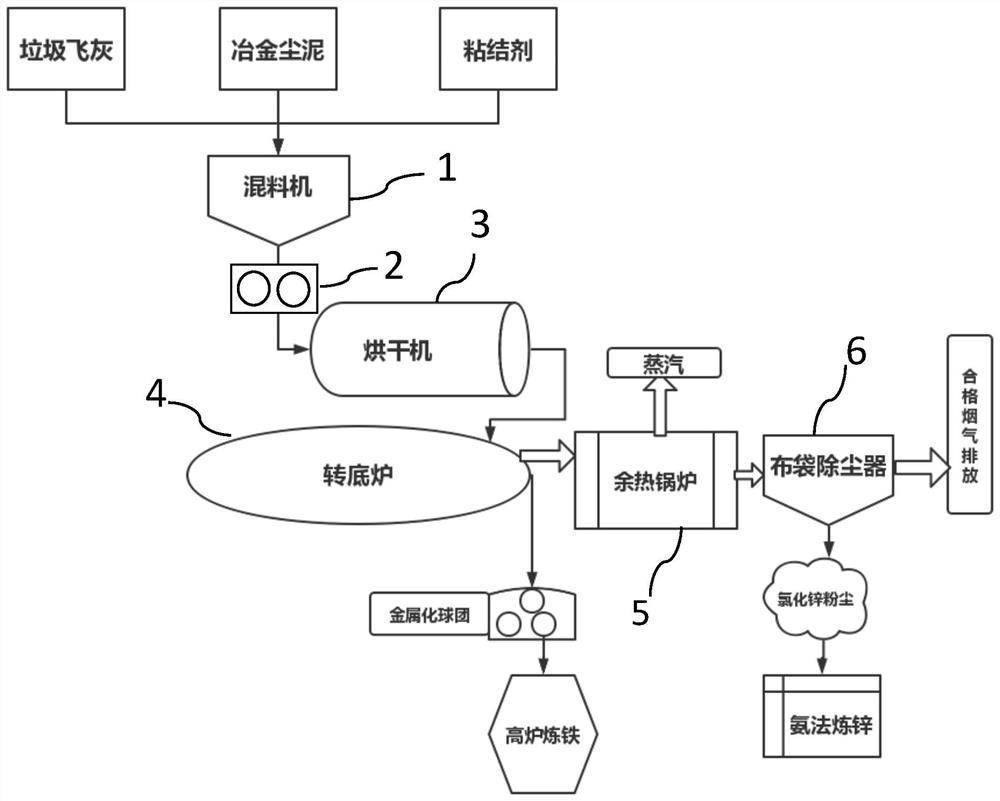

[0062] In the present embodiment, the method for co-processing waste incineration fly ash using rotary hearth furnace is as follows:

[0063] Iron and steel metallurgical dust sludge composition: iron content 42%. Carbon content 8.5%, zinc content: 2.0%, chlorine content 0.48%;

[0064] Garbage fly ash contains 30% CaO, 18% Cl, 150ng / g dioxin,

[0065] The metallurgical dust sludge, garbage fly ash, binder and water are mixed in a ratio of 100:8:1.5:12 by weight, and pressed to obtain carbon-containing pellets, wherein the cost of the binder is reduced by 50%; The content of iron in the dry base is 38.4wt%, the zinc content is 1.96wt%, the chlorine content is 1.9wt%, and the dioxin is 12ng / g.

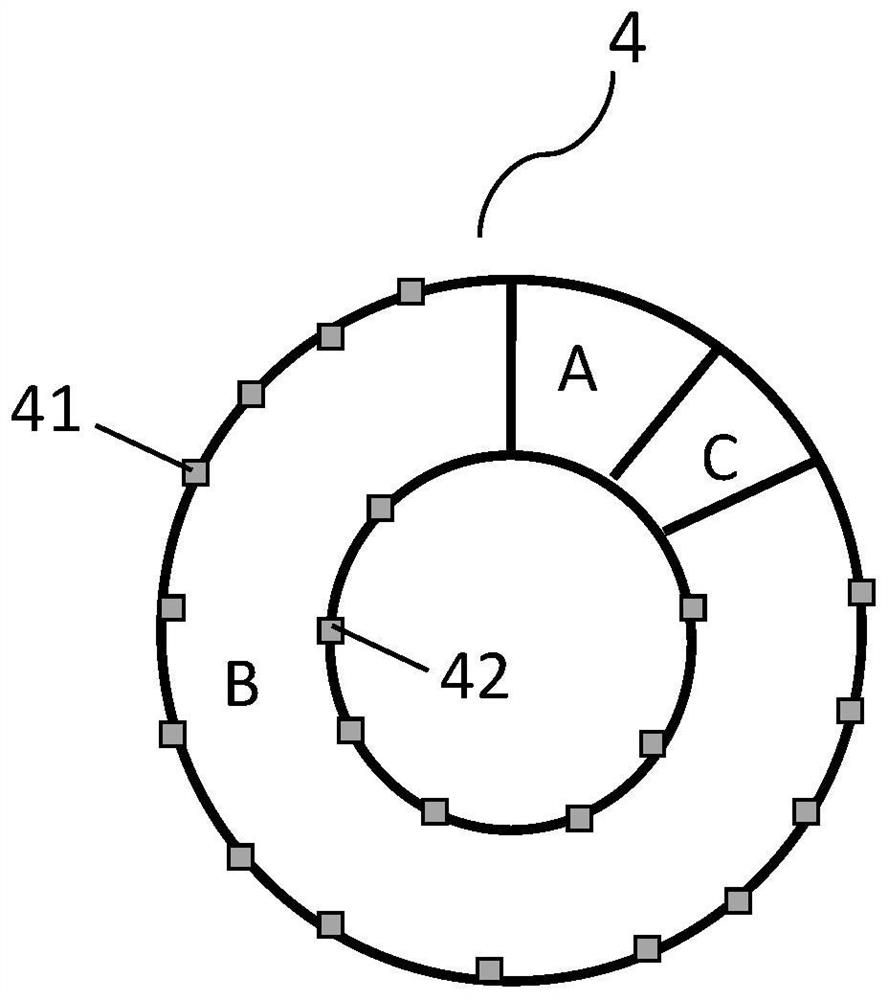

[0066] The carbon-containing pellets were sent to a dryer for drying, and the drying temperature was set to 200° C. The moisture content of the carbon-containing pellets after drying was 0.79 wt%. Reduction roasting, the temperature in the preheating zone of the rotary hearth furnace...

Embodiment 2

[0071] In the present embodiment, the method for co-processing waste incineration fly ash using rotary hearth furnace is as follows:

[0072] Composition of iron and steel metallurgical dust sludge: iron content of 45%. Carbon content 10, zinc content: 2.4%, chlorine content 0.45%;

[0073] Garbage fly ash contains 38% CaO, 15% Cl, 100ng / g dioxin,

[0074] The metallurgical dust sludge, garbage fly ash, binder and water are mixed in a ratio of 100:6:2:10.5 by weight, and pressed to obtain carbon-containing pellets, wherein the cost of the binder is reduced by 40%; The content of iron in the dry base is 41.4wt%, the zinc content is 2.2wt%, the chlorine content is 1.5wt%, and the dioxin is 5.8ng / g.

[0075] The carbon-containing pellets were sent to a dryer for drying, and the drying temperature was set at 190°C. The moisture content of the carbon-containing pellets after drying was 0.9 wt%. For reduction roasting, the temperature in the preheating zone of the rotary hearth f...

Embodiment 3

[0080] In the present embodiment, the method for co-processing waste incineration fly ash using rotary hearth furnace is as follows:

[0081] Composition of iron and steel metallurgical dust sludge: iron content of 18%. Carbon content 11, zinc content: 2.8%, chlorine content 0.49%;

[0082] The content of garbage fly ash is 44% CaO, 10% Cl, 40ng / g dioxin,

[0083] The metallurgical dust sludge, garbage fly ash, binder and water are mixed and pressed in a ratio of 100:5:2.5:10.5 by weight to obtain carbon-containing pellets, wherein the cost of the binder is reduced by 30%; The content of iron in the dry base is 44.65wt%, the zinc content is 2.6wt%, the chlorine content is 0.92wt%, and the dioxin is 3.72ng / g.

[0084] The carbon-containing pellets were sent to a dryer for drying, and the drying temperature was set to 180° C. The moisture content of the carbon-containing pellets after drying was 0.73 wt%. Reduction roasting, the temperature in the preheating zone of the rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com