Surfactant compounded system with ultralow interfacial tension and preparation method of surfactant compounded system

A surfactant and interfacial tension technology, applied in chemical instruments and methods, dissolving, drilling compositions, etc., can solve the problems of difficult crude oil recovery, enhanced water sensitivity, and high dosage of alkali agents, and achieve improved crude oil recovery. Yield, good performance, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of ultra-low interfacial tension surfactant complex system of the present embodiment, by mass percentage, comprises 10% amphoteric surfactant, 20% nonionic surfactant polyether, 2% stabilizer secondary alkyl Sodium sulfonate, the balance is water.

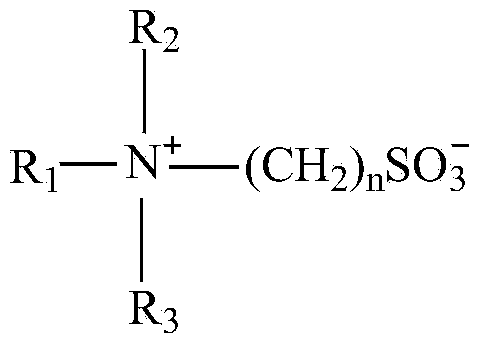

[0034] Described amphoteric surfactant is dodecyl dimethyl sulfopropyl betaine, and structural formula is as follows:

[0035]

[0036] The preparation method of the low interfacial tension surfactant complex system of the present embodiment is as follows:

[0037] Under normal temperature and pressure, sequentially add amphoteric surfactant, nonionic surfactant, and stabilizer into the reaction kettle, mix well, then add water, stir well until the liquid is transparent, and the product is obtained after discharge.

[0038] Carry out performance test to present embodiment product, test condition:

[0039] 1. Test instrument: TX-500C spinning drop interfacial tensiometer;

[0040] 2. Test temperature: 60°C;

[0...

Embodiment 2

[0046] A kind of ultra-low interfacial tension surfactant composite system of the present embodiment, by mass percent, comprises 15% amphoteric surfactant, 20% nonionic surfactant alkanolamide, 3% stabilizer + Sodium dialkylsulfonate, the balance is water.

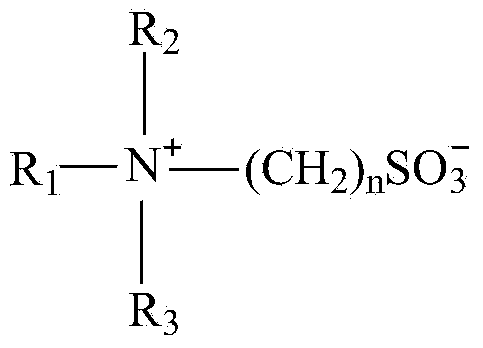

[0047] Described amphoteric surfactant is octadecyldimethylsulfopropyl betaine, and structural formula is as follows:

[0048]

[0049] The preparation method of the low interfacial tension surfactant complex system of the present embodiment is as follows:

[0050] Under normal temperature and pressure, sequentially add amphoteric surfactant, nonionic surfactant, and stabilizer into the reaction kettle, mix well, then add water, stir well until the liquid is transparent, and the product is obtained after discharge.

[0051] Carry out performance test to present embodiment product, test condition:

[0052] 1. Test instrument: TX-500C spinning drop interfacial tensiometer;

[0053] 2. Test temperature: 60°C;

[0054] ...

Embodiment 3

[0059] A kind of ultra-low interfacial tension surfactant composite system of the present embodiment, by mass percent, comprises 20% amphoteric surfactant, 20% nonionic surfactant (alkanolamide and dodecyl sulfonate sodium dodecyl sulfate mixture), 4% of the stabilizer sodium dodecyl sulfate, and the balance is water.

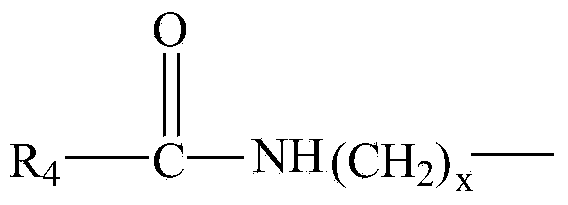

[0060] Described amphoteric surfactant is lauryl amidopropyl dimethylsulfopropyl betaine, and structural formula is as follows:

[0061]

[0062] The preparation method of the low interfacial tension surfactant complex system of the present embodiment is as follows:

[0063] Under normal temperature and pressure, sequentially add amphoteric surfactant, nonionic surfactant, and stabilizer into the reaction kettle, mix well, then add water, stir well until the liquid is transparent, and the product is obtained after discharge.

[0064] Carry out performance test to present embodiment product, test condition:

[0065] 1. Test instrument: TX-500C spinning drop i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com