Method for repairing and regenerating aged suspended biological membrane filler

A technology of restoration regeneration and biological filler, which is applied in the field of environmental biotechnology and water treatment, can solve the problems of low biofilm activity, poor treatment effect, and non-renewal of biofilm, and achieve convenient operation, low price, efficient renewal and reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method for repairing and renewing biofilm in a bioreactor for wastewater treatment comprises the following steps: the method comprises the following steps:

[0035] 1) taking out the aging biofilm of the suspended biofiller in the biofilm reactor and drying it;

[0036] 2) Start the vibrating screen stripping treatment device, the suspended filler is covered with biofilm, and the vibrating screen regularly vibrates the biofilm to make the aging and loose biofilm and the waste water sludge accumulated here fall off and then discharge;

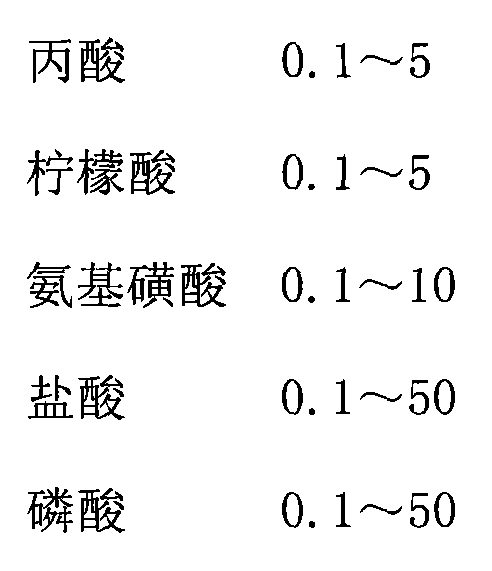

[0037] 3) Acid-base chemical elution; use 5% acid wash first, then 5% alkali wash;

[0038] 4) The enzyme preparation is further eluted; the enzyme preparation is a protease;

[0039] 5) dry the filler after step 4), and put the filler back into the biofilm reactor;

[0040] 6) Regeneration of biofilm; continue to feed air or oxygen, and add trace element nutrient solution to realize the final renewal of biofilm; the formula of sai...

Embodiment 2

[0049] A method for repairing and renewing biofilm in a bioreactor for wastewater treatment, comprising the following steps:

[0050] 1) A vibrating sieve is set in the bioreactor, including a sieve body, a base, a shelf, several springs, vibration power, and a transmission rod. Biofilm, several springs are set between the base and the shelf, the transmission rod is connected between the vibrating power and the shelf, and the vibrating screen is connected with the electric control system. The vibration power is turned on through the electronic control system, and the vibration power drives the transmission rod to start the vibrating screen. The vibrating screen vibrates the biofilm regularly and continuously, so that the aging and loose biofilm and the waste water sludge accumulated here will fall off and then discharged. ;

[0051] 2) Add anaerobic and / or aerobic strains to the above-mentioned vibrating screen where the suspended packing is placed, and continue to feed air or ...

Embodiment 3

[0058] A method for repairing and renewing biofilm in a bioreactor for wastewater treatment, comprising the following steps:

[0059] 1) A vibrating sieve is set in the bioreactor, including a sieve body, a base, a shelf, several springs, vibration power, and a transmission rod. Biofilm, several springs are set between the base and the shelf, the transmission rod is connected between the vibrating power and the shelf, and the vibrating screen is connected with the electric control system. The vibration power is turned on through the electronic control system, and the vibration power drives the transmission rod to start the vibrating screen. The vibrating screen vibrates the biofilm regularly and continuously, so that the aging and loose biofilm and the waste water sludge accumulated here will fall off and then discharged. ;

[0060] 2) Add anaerobic and / or aerobic strains to the above-mentioned vibrating screen where the suspended packing is placed, and continue to feed air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com