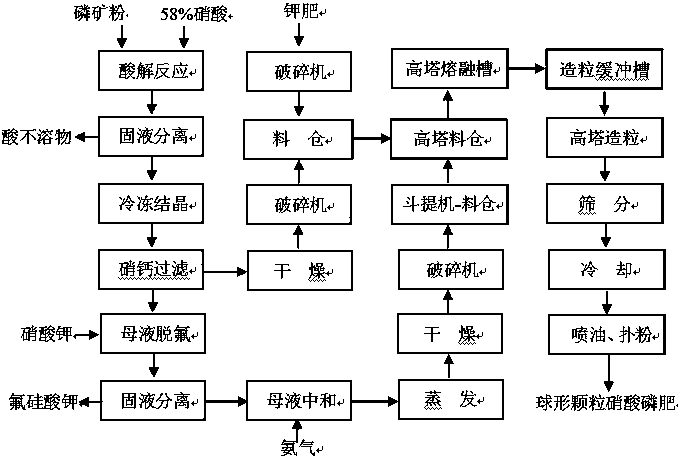

Improved process for producing spherical and granulated nitrogen-phosphorus-potassium mixed fertilizer based on nitrophosphate fertilizer device

A nitrogen-phosphorus-potassium compound fertilizer and spherical particle technology, which is applied in fertilization devices, nitrate fertilizers, fertilizer forms, etc., can solve the problems of unsightly appearance of products, complex composition of NP slurry, easy to block pipes and equipment, etc. Achieve the effect of improving process conditions and equipment parameters, reducing temperature, saving energy consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1, the preparation of potassium calcium fertilizer

[0045] The calcium nitrate filter cake and potassium nitrate obtained by the filtration of the calcium nitrate freezing and crystallization process are added to the dryer at a mass ratio of 6:1 for drying. After the water content is reduced to less than 3%, it is crushed into a particle size of less than 5cm by a crusher. particles, obtain K 2 Potassium calcium fertilizer with O content of 13.45%, CaO content of 18.20%, and water content of 3%.

[0046] Step 2. Preparation of Nitrophosphate Fertilizer

[0047] The NP slurry obtained by evaporation in the mother liquor evaporation process is subjected to a drying process to control the water content to be less than 0.6%, and then crushed into particles with a particle size of less than 5 cm by a crusher to obtain a N content of 35.2%, P 2 O 5 Nitrophosphate fertilizer with a content of 24.6% and a water content of 0.6%.

[0048] Step 3, the preparation of powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com