Composition, in an aqueous medium, including at least one hyaluronic acid and at least one sucrose octasulphate water-soluble salt

A technology of sucrose octasulfate and water-soluble salt, which is applied in the direction of drug combination, medical preparations containing active ingredients, allergic diseases, etc., to achieve the effect of high persistence and long half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

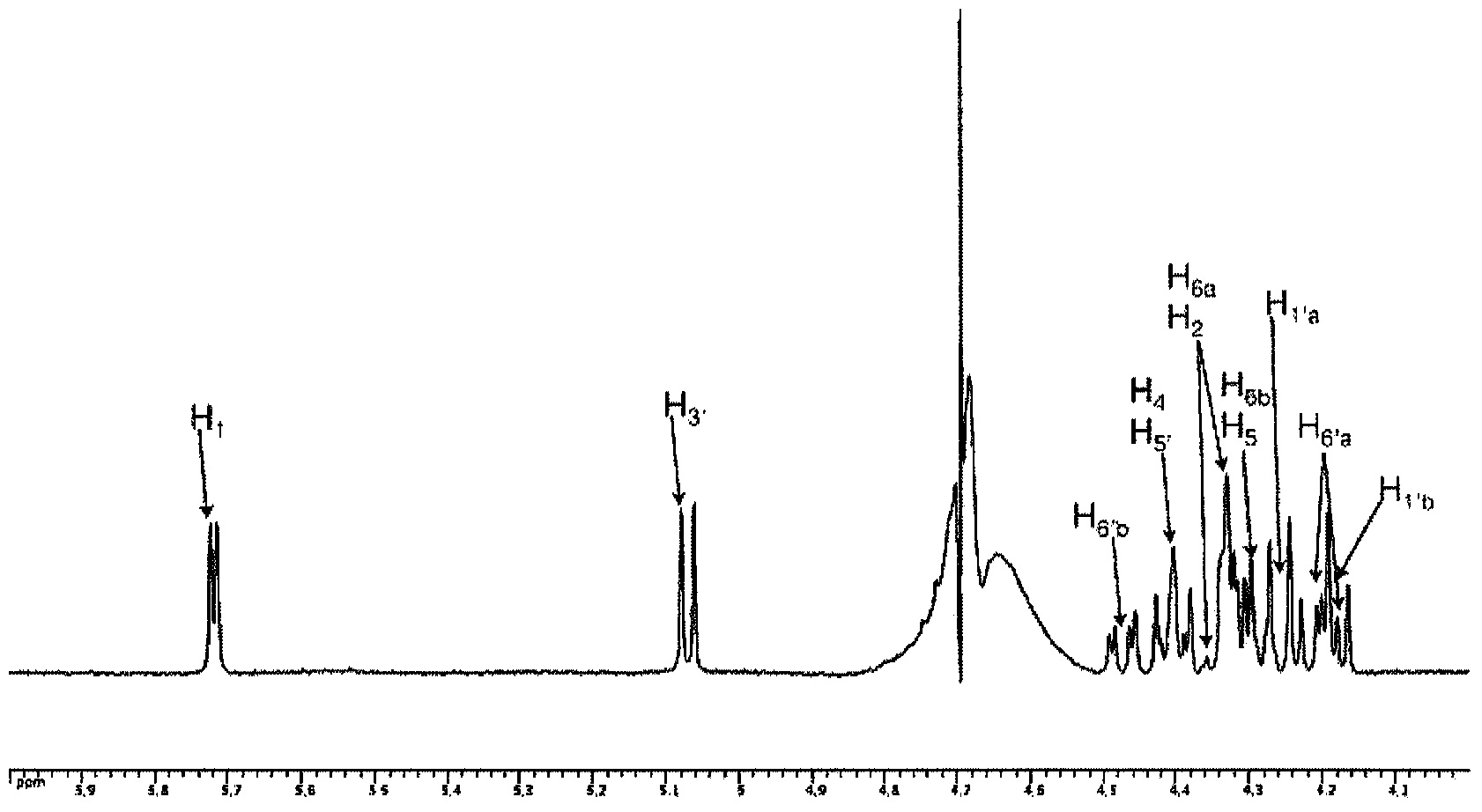

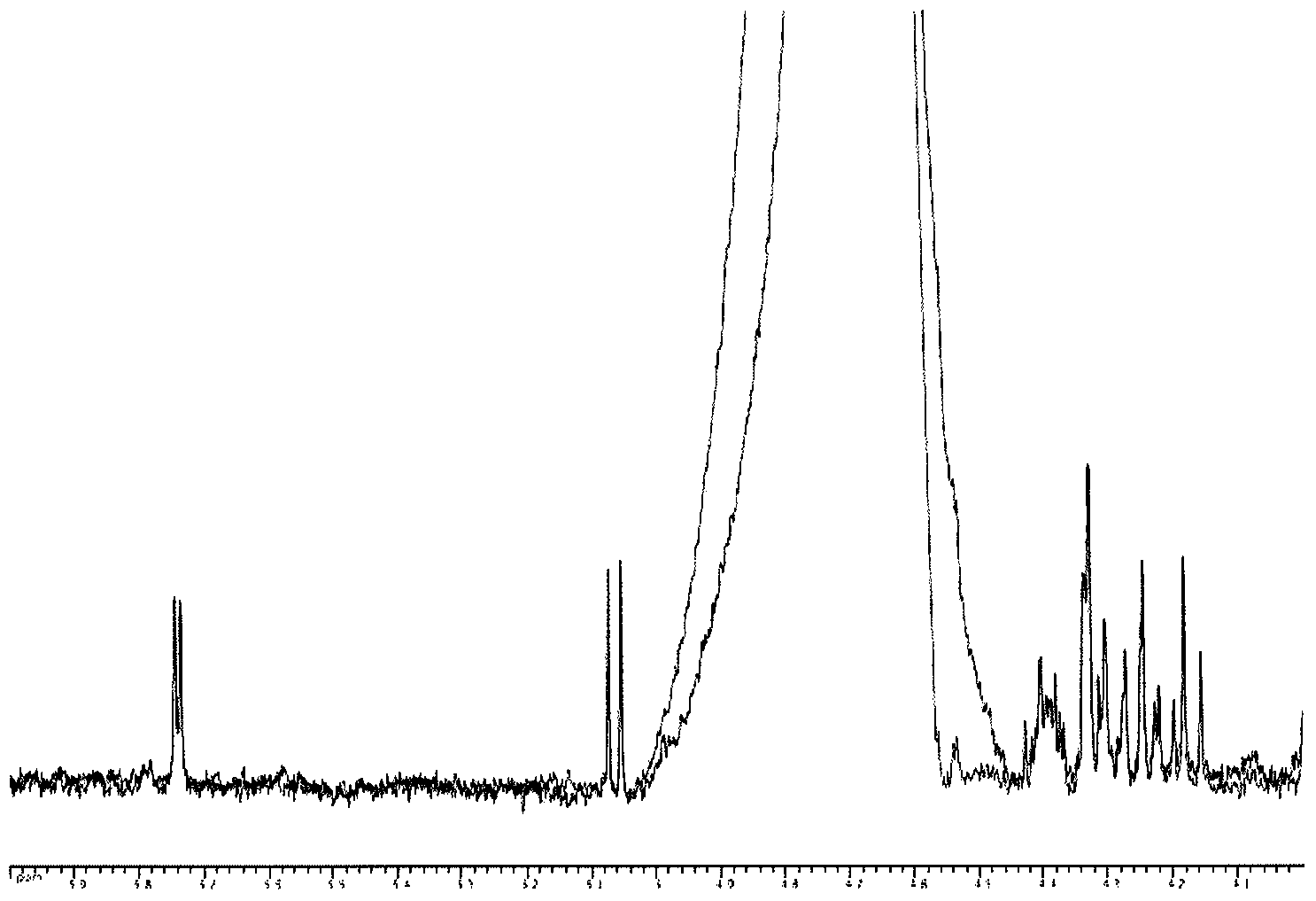

[0157] This example illustrates a composition according to the invention comprising non-crosslinked hyaluronic acid and potassium sucrose octasulfate.

[0158] Injectable grade sodium hyaluronate (NaHA) fibers (1 g; molecular weight: about 2.7 MDa) were weighed in a container. Phosphate buffered saline solution (32.3 g) was added, and the whole material was homogenized with a spatula for about 1 hour at room temperature and an atmospheric pressure of 900 mmHg.

[0159] The NaHA concentration of the thus obtained non-crosslinked NaHA hydrogel was about 30 mg / g.

[0160] Potassium sucrose octasulfate (KSOS) (60mg, 4.7×10 -5 mol) was dissolved in a phosphate buffer solution (19.94 g) to obtain an aqueous solution of potassium sucrose octasulfate with a concentration of 3 mg / g.

[0161] Dilute the NaHA hydrogel obtained in the preceding steps by adding the aqueous solution of potassium sucrose octasulfate prepared above. The composition thus obtained is subsequently homogenized...

Embodiment 2

[0166] This example illustrates a composition according to the invention comprising cross-linked hyaluronic acid and potassium sucrose octasulfate.

[0167] According to the cross-linking method described in WO 2009 / 071697 (Example 1, Part 1) in the name of Vivacy, sodium hyaluronate (NaHA) fibers (1 g; molecular weight: about 2.7 MDa) and butanediol diglycidol Ether (BDDE) (54 mg) was used as starting material to prepare a composition comprising cross-linked hyaluronic acid. The composition thus obtained had a crosslinking NaHA concentration of about 30 mg / g and a degree of crosslinking X of about 0.12.

[0168] An aqueous solution of potassium sucrose octasulfate with a concentration of 3 mg / g was prepared according to Example 1.

[0169] Dilute the cross-linked NaHA hydrogel obtained in the previous steps in the aqueous solution of potassium sucrose octasulfate prepared above. The composition thus obtained is subsequently homogenized.

[0170] This resulted in a composit...

Embodiment 3

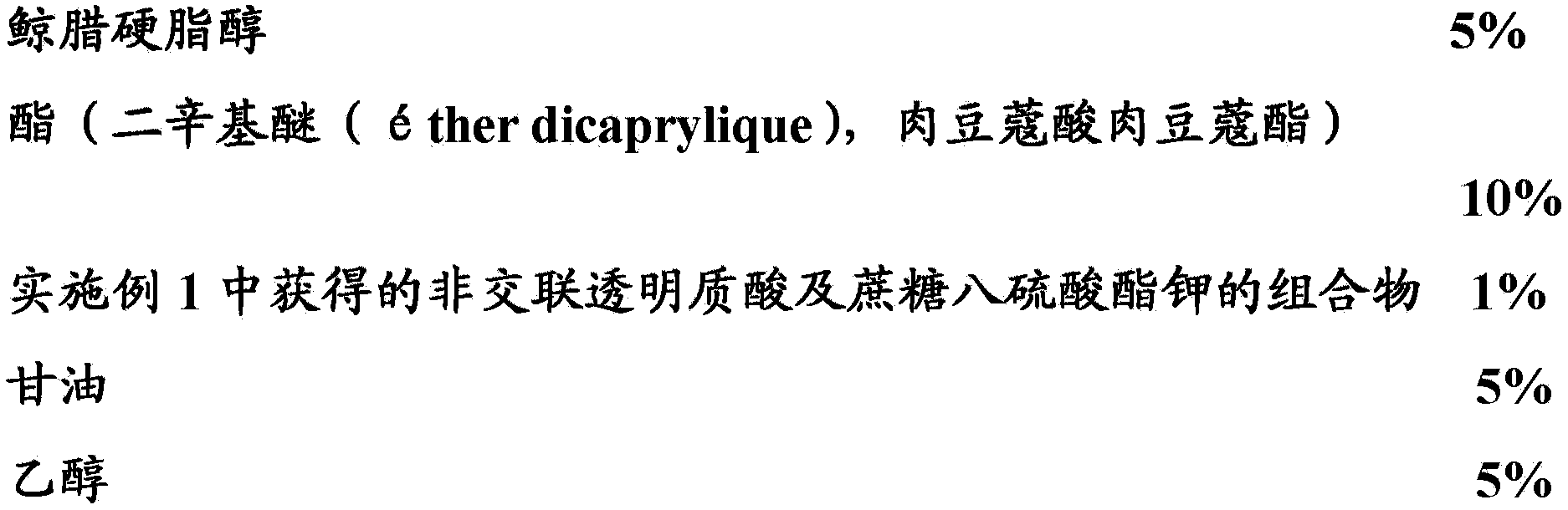

[0174] This example illustrates an exemplary composition comprising non-crosslinked hyaluronic acid, potassium sucrose octasulfate, and mannitol according to the invention.

[0175] According to the method of Example 1, using the aqueous solution of hyaluronic acid hydrogel at a concentration of 30 mg / g and potassium sucrose octasulfate at a concentration of 10 mg / g as raw materials, a gel containing non-crosslinked hyaluronic acid and potassium sucrose octasulfate was prepared. combination.

[0176] The addition of a 86 mg / g concentration of mannitol solution to the composition obtained above was carried out according to the method described in WO 2009 / 024670 in the name of Anteis.

[0177] The composition thus obtained comprises non-crosslinked NaHA at a concentration of 20 mg / g, mannitol at a concentration of 20 mg / g, and potassium sucrose octasulfate at a concentration of 1 mg / g; thus [HA] / [SOS by weight ] with a ratio of 20.

[0178] The composition obtained above was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com