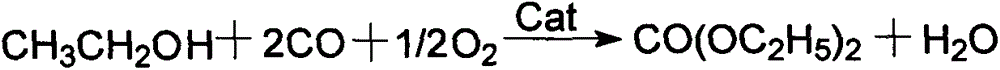

Carbon nanotube-graphene catalyst for synthesizing diethyl carbonate, and preparation method thereof

A technology of diethyl carbonate and carbon nanotubes, applied in the field of gas-phase catalytic synthesis of diethyl carbonate, can solve the problems of poor catalyst stability, equipment corrosion, low catalyst activity, etc., and achieve the effect of stable activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

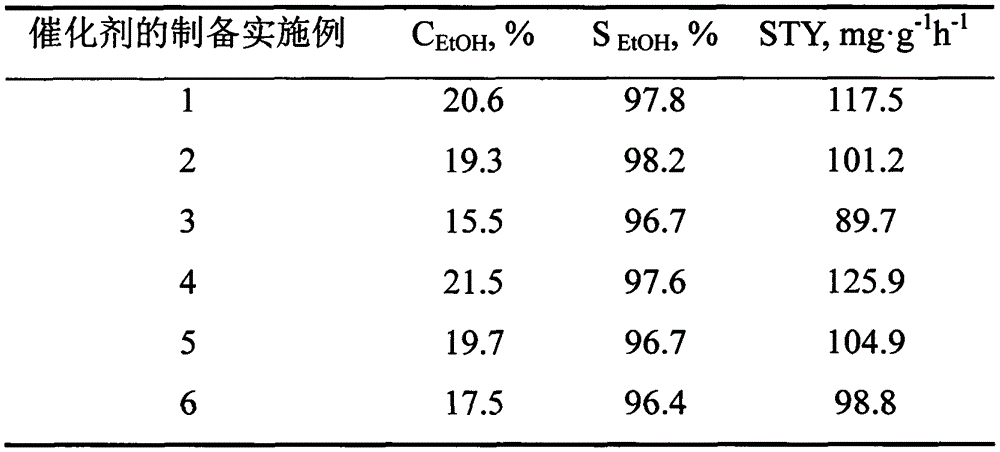

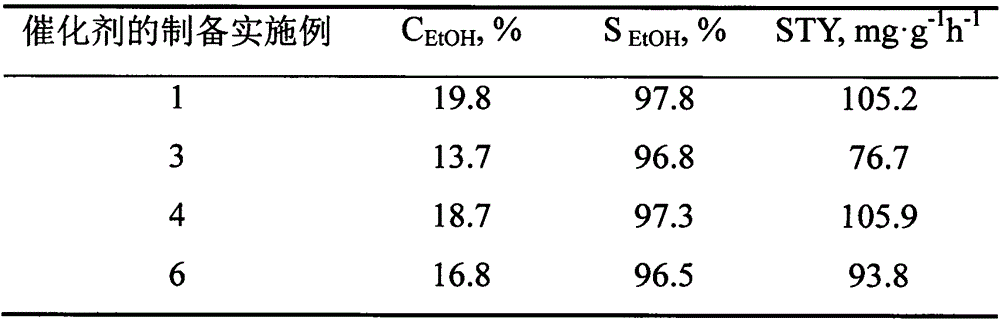

Examples

Embodiment 1

[0014] First, bake 2 g of dried graphite oxide in a muffle furnace at 900°C for 1 h to obtain expanded graphite; then dope copper on the expanded graphite, that is, immerse the expanded graphite in 40 ml of an aqueous solution of 1 mol / L ammonium carbonate. CuCl 2 Add 10ml of 0.5g aqueous solution dropwise into the above solution, stir, stand still, filter, dry, roast for 1 hour and grind into 2.3g of fine powder; finally put the above fine powder into a chemical vapor deposition furnace, pass through carbon The source gas was methane, and a composite of copper-doped carbon nanotubes and graphene was obtained by chemical vapor deposition, and then 3 g of copper-containing carbon nanotubes and graphene were added to 50 mL of PdCl 2 Immersed in methanol solution for 4h, rotary steamed and molded to obtain 3g of copper palladium carbon nanotube-graphene catalyst.

Embodiment 2

[0016] Under the situation that the preparation condition of catalyst is exactly the same as embodiment 1, only change the copper source in the preparation method into Cu(NO 3 ) 2 copper salt to obtain 3 g of catalyst.

Embodiment 3

[0018] Under the situation that the preparation condition of catalyzer is completely identical with embodiment 1, only change the copper source in the preparation method into Cu(CH 3 COO) 2 ·H 2 0 copper salt to obtain catalyst 3g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com