Sealing nutrient soil used for well-cellar flue-cured tobacco transplanting and preparation method for sealing nutrient soil

A pit-type, nutritious soil technology, applied in the direction of application, nitrogen fertilizer, inorganic fertilizer, etc., to achieve the effect of improving soil, ensuring the effect, and promoting early growth and rapid development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

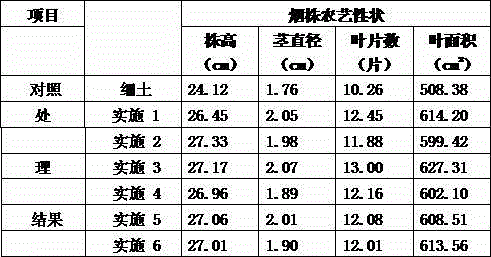

Embodiment 1

[0033] Example 1 Follow the steps below to prepare flue-cured tobacco pit-type transplanting and sealing nutrient soil

[0034] First, select the raw ore of granite weathering debris, pass through a 10-mesh sieve, and take 68.0 kg of granite weathering debris for later use; collect slag from a thermal power plant, crush it through a 10-mesh sieve, and take 12.0 kg of fine slag for later use; use biomass materials such as straw, Hay, branches, leaves, sawdust, etc. were heated in a biomass carbonization furnace to prepare biochar, crushed through a 10-mesh sieve, and then 6.0 kg of charcoal powder was taken for use; the above-mentioned reserve materials were mixed with P 2 o 5 6.0kg of phosphate rock powder ≥15%, 4.5kg of calcium magnesium phosphate fertilizer meeting national standards, 1.5kg of potassium chloride, 1.5kg of ammonium nitrate and 0.5kg of diammonium phosphate, mix well, and finally stir evenly with a mixer to get flue-cured tobacco well 100kg of nutrient soil...

Embodiment 2

[0035] Example 2 According to the steps of Example 1, 100 kg of flue-cured tobacco pit type transplanting and sealing nutrient soil were prepared, and the amount of each raw material was: 70.0 kg of weathered granite debris, 14.0 kg of fine slag from a thermal power plant, 7.0 kg of biomass charcoal powder, containing P 2 o 5 ≥15% phosphate rock powder 4.0kg, calcium magnesium phosphate fertilizer meeting national standards 2.5kg, potassium chloride 1.0kg, ammonium nitrate 1.0kg and diammonium phosphate 0.5kg.

Embodiment 3

[0036] Example 3 According to the steps of Example 1, 100 kg of flue-cured tobacco pit type transplanting and sealing nutrient soil were prepared, and the amount of each raw material was: 72.0 kg of weathered granite debris, 14.0 kg of fine slag from a thermal power plant, 6.0 kg of biomass charcoal powder, containing P 2 o 5 6.0kg of phosphate rock powder ≥15%, 2.5kg of calcium magnesium phosphate fertilizer meeting national standards, 0.5kg of potassium chloride, 0.5kg of ammonium nitrate and 0.5kg of diammonium phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com