A preparation method of molecularly imprinted material for fluorescent selective recognition of cyhalothrin

A technology of cyhalothrin and molecular imprinting, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of low yield, slow mass transfer rate and difficult elution of molecularly imprinted polymers, and achieve strong selective recognition performance , wide detection range, and good monodisperse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

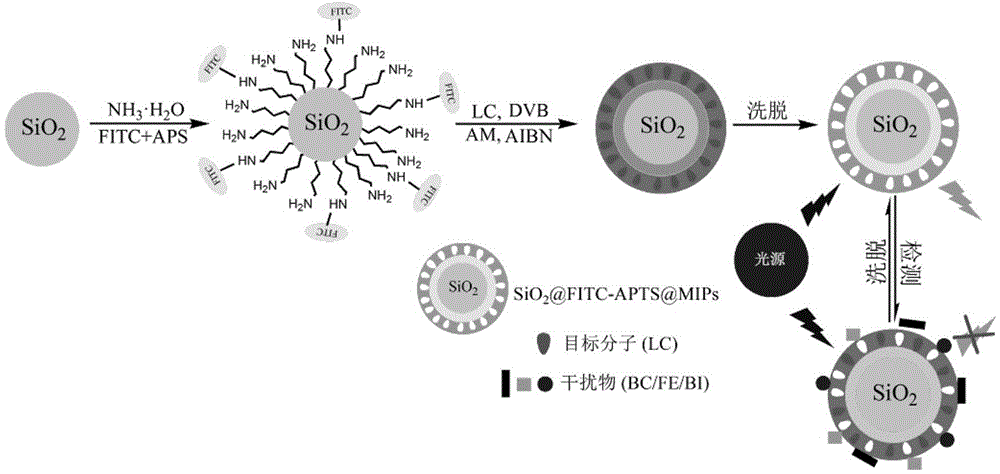

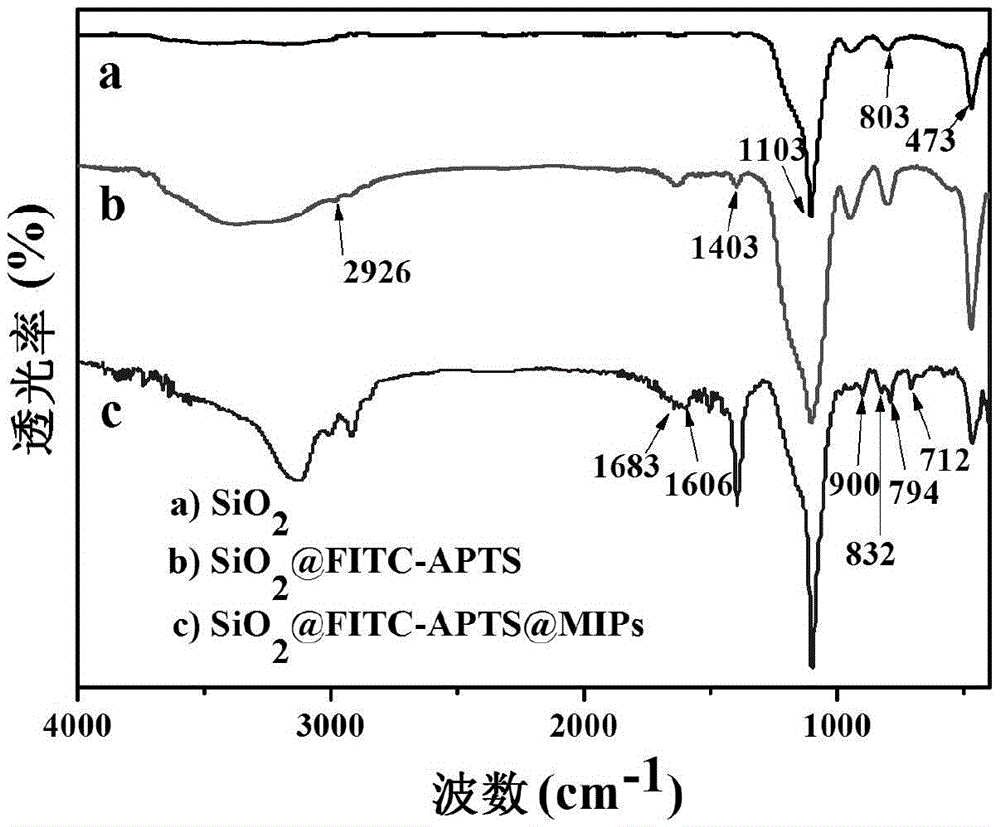

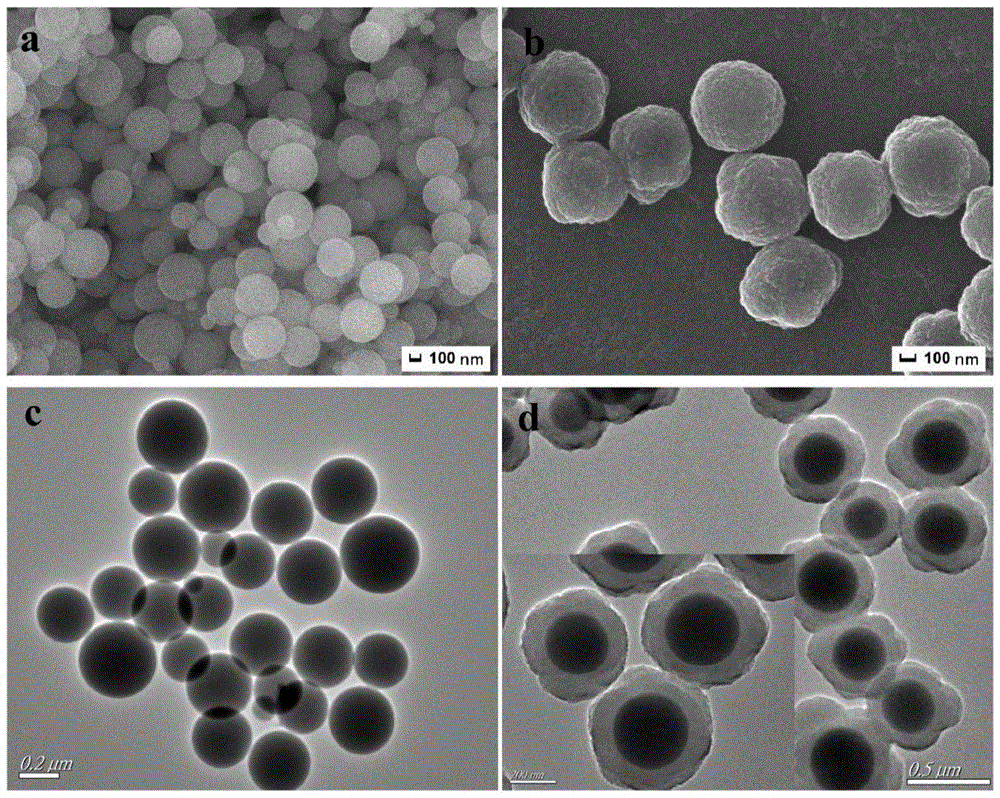

[0030] SiO prepared by the Stöver method 2 Nanospheres were added to every 100 mL of ethanol and distilled water at a ratio of 10:3, (v / v) 5.0 mL of ammonia-water mixture, and stirred continuously after ultrasonication for 30 minutes; Aminopropyltriethoxysilane (APTS) was mixed and continuously stirred for 24 hours, and then slowly dropped into the above dispersion liquid. After the dropwise addition, it was kept under room temperature and kept stirring for another 24 hours; after the reaction, ethanol and After being washed several times with distilled water, it was collected by a high-speed centrifuge and dried overnight in a vacuum oven at 40°C to obtain SiO 2 @FITC - APTS microspheres. FTIR as figure 2 shown.

Embodiment 2

[0032] The SiO obtained in 200 mg embodiment 1 2 @FITC-APTS microspheres were ultrasonically dispersed in 70 mL of acetonitrile, and 0.50 mmol of template molecules (cyhalothrin, LC), 2.0 mmol of functional monomers (acrylamide, AM) and 0.4 mL of cross-linking agent (divinyl Benzene, DVB). Self-assembled at room temperature for 12 hours, after the functional monomers and template molecules fully interacted, 2.5% of the initiator azobisisobutyronitrile (AIBN) based on the total amount of the monomers was added. Air was purged by bubbling nitrogen gas for 15 minutes, and sealed under nitrogen atmosphere. Thermally initiated polymerization was used, and it was placed in a constant temperature oil bath at 60°C for 24 h to react. After the polymerization was completed, a pale yellow precipitated polymer was obtained. Soxhlet extraction and elution with a solution of methanol: acetic acid at 9:1 (V / V) to remove cyhalothrin, and then soak the precipitate repeatedly with methanol so...

Embodiment 3

[0034] The SiO obtained in 200 mg embodiment 1 2 @FITC-APTS microspheres were ultrasonically dispersed in 70 mL of acetonitrile, and 0.75 mmol of template molecules (cyhalothrin, LC), 3.0 mmol of functional monomers (acrylamide, AM), and 0.6 mL of cross-linking agent (diethylene phenylene, DVB). Self-assembled at room temperature for 12 hours, after the functional monomers and template molecules fully interacted, 2.5% of the initiator azobisisobutyronitrile (AIBN) based on the total amount of the monomers was added. Air was purged by bubbling nitrogen gas for 15 minutes, and sealed under nitrogen atmosphere. Thermally initiated polymerization was used, and it was heated in a constant temperature oil bath at 60 °C for 24 h. After the polymerization was completed, a pale yellow precipitated polymer was obtained. Soxhlet extraction and elution with a solution of methanol: acetic acid at 9:1 (V / V) to remove cyhalothrin, and then soak the precipitate repeatedly with methanol solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com