A kind of flame retardant car roof material and preparation method thereof

A technology for a roof and a flame retardant, which is applied in the field of automotive interior materials, can solve the problems of insufficient heat resistance, insufficient flame retardancy, high environmental hazard, etc., and achieves good processing performance and mechanical performance, flame retardant The effect is obvious and the service life is long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 36kg of polypropylene, 20kg of trimethylolpropane trimethacrylate, 20kg of hydroxypropyl methylcellulose, 15kg of EPDM rubber, 12kg of polyvinyl alcohol, 5kg of ammonium polyphosphate, 1, 5kg of 2-indane, 3kg of corundum powder and 1kg of zinc oxide nanoparticles;

[0031] (2) Put the above raw materials into a homogenizer and mix them thoroughly, add 2kg of polyspirocyclophosphate diamide and 2kg of polyhexamethylene biguanide salt to the mixed materials and send them into the twin-screw extruder, Shearing, extrusion, granulation;

[0032] The temperature of each section of the twin-screw extruder is: 160°C in the first zone, 165°C in the second zone, 170°C in the third zone, and 180°C in the fourth zone.

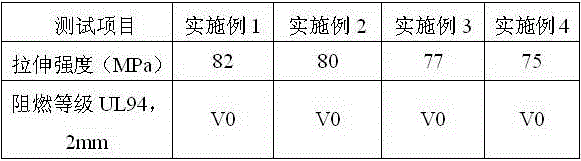

[0033] The performance test results of the prepared flame-retardant car roof materials are shown in Table 1.

Embodiment 2

[0035] (1) Weigh 36kg of polypropylene, 30kg of trimethylolpropane trimethacrylate, 30kg of hydroxypropyl methylcellulose, 20kg of EPDM rubber, 8kg of polyvinyl alcohol, 3kg of ammonium polyphosphate, 1, 2-indane 2kg and corundum powder 2kg;

[0036] (2) Put the above-mentioned raw materials into a homogenizer and mix them thoroughly, add 5kg of polyspirocyclic phosphate diamide and 1kg of polyhexamethylenediamine guanidine salt to the mixed materials and send them into the twin-screw extruder, after being sheared by the screws, cutting, extrusion, granulation;

[0037] The temperature of each section of the twin-screw extruder is: 160°C in the first zone, 165°C in the second zone, 170°C in the third zone, and 180°C in the fourth zone.

[0038] The performance test results of the prepared flame-retardant car roof materials are shown in Table 1.

Embodiment 3

[0040] (1) Weigh 38kg of polypropylene, 25kg of trimethylolpropane trimethacrylate, 25kg of hydroxypropyl methylcellulose, 18kg of EPDM rubber, 10kg of polyvinyl alcohol, 4kg of ammonium polyphosphate, 1, 2-indane 3kg, corundum powder 2kg and zinc oxide nanoparticles 2kg;

[0041] (2) Put the above raw materials into a homogenizer and mix them thoroughly, add 3kg of melamine cyanurate to the mixed materials and send them into a twin-screw extruder, extrude and granulate through the shearing action of the screws;

[0042] The temperature of each section of the twin-screw extruder is as follows: the first zone is 165°C, the second zone is 170°C, the third zone is 180°C, and the fourth zone is 190°C.

[0043] The performance test results of the prepared flame-retardant car roof materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com