Building plastic formwork and preparation method thereof

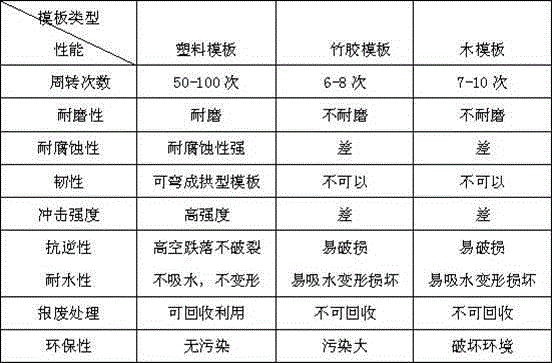

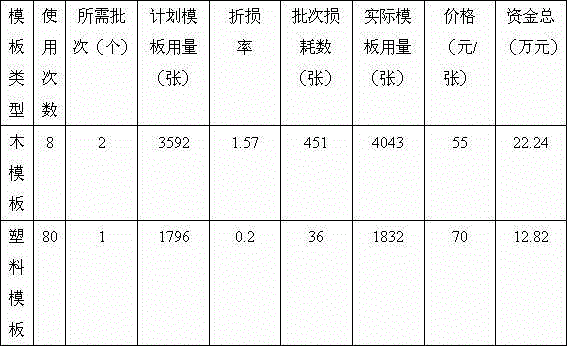

A plastic formwork and construction technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of waterproof layer damage, difficult recycling, damage, etc., and achieve less cleaning, high turnover rate, and good water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) The mass percentages of raw materials for the preparation of the middle layer are as follows: 25% polyethylene, 45% polypropylene copolymer, 20% polypropylene fiber, 7% double fly powder and 3% polyether modified polysiloxane, heat the mixer to 38 ℃, and then add the above-mentioned raw material components into the mixer and mix for 10 minutes.

[0030] 2) Feed the homogeneously mixed material in step 1) to the plastic single-screw extruder SJ90 for plasticization. The temperature is 170°C, the temperature in the fourth zone is 180°C, the temperature in the fifth zone is 190°C, the temperature in the sixth zone is 170°C, and the screw speed is 50 rpm.

[0031] 3) Feed the copolymerized polypropylene to another plastic single-screw extruder SJ90 for plasticization, and control the temperature of the first zone of the single-screw extruder barrel to 160°C, the temperature of the second zone to 165°C, and the temperature of the third zone to 170 ℃, the temperature i...

Embodiment 2

[0044] 1) The mass percentages of raw materials for the preparation of the middle layer are as follows: 35% polyethylene, 42.5% polypropylene copolymer, 18% polypropylene fiber, 3% double fly powder and 1.5% carboxylic acid-N-alkylamide, heat the mixer to 38 ℃, and then add the above-mentioned raw material components into the mixer and mix for 15 minutes.

[0045] 2) Feed the homogeneously mixed materials in step 1) to the single-screw extruder SJ90 for plasticization, and control the temperature of the first zone of the barrel of the single-screw extruder to 195°C, the temperature of the second zone to 170°C, and the temperature of the third zone The temperature in zone 4 is 180°C, the temperature in zone 4 is 190°C, the temperature in zone 5 is 180°C, the temperature in zone 6 is 180°C, and the screw speed is 80 rpm.

[0046] 3) Feed the copolymerized polypropylene into another single-screw extruder SJ90 for plasticization, and control the temperature of the barrel of the...

Embodiment 3

[0049] 1) The mass percentages of raw materials for the preparation of the middle layer are as follows: 31% polyethylene, 37.5% polypropylene copolymer, 25% polypropylene fiber, 5% double fly powder and 1.5% polyether modified polysiloxane, heat the mixer to 42°C , and then add the above-mentioned raw material components into the mixer and mix for 13 minutes.

[0050] 2) Feed the homogeneously mixed material in step 1) into the single-screw extruder for plasticization, and control the temperature of the first zone of the single-screw extruder barrel to 190°C, the temperature of the second zone to 165°C, and the temperature of the third zone to be 175°C, the temperature in the fourth zone is 185°C, the temperature in the fifth zone is 185°C, the temperature in the sixth zone is 170°C, and the screw speed is 70 rpm.

[0051] 3) Feed the copolymerized polypropylene to another single-screw extruder for plasticization, and control the temperature of the barrel of the single-scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com