Solar battery backboard modified PET (polyethylene glycol terephthalate) base material and preparation method thereof

A technology for solar cells and back sheets, which is applied in the field of modified PET substrates for solar cell back sheets and their preparation, can solve the problems of general connection force, easy peeling and falling off, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

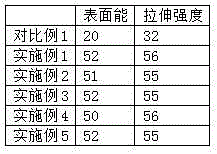

Examples

Embodiment 1

[0028] A modified PET base material for a solar battery back sheet, comprising the following components in parts by weight: 50 parts of n-butyl acetate, 60 parts of PET, 70 parts of hexabromocyclododecane, 3-methyl-2-butene- 90 parts of 1-alcohol, 150 parts of methyl ethyl ketone, 60 parts of titanium dioxide, 40 parts of maleic anhydride grafted polypropylene, 80 parts of stabilizer, 70 parts of carbonate, 35 parts of phthalates.

[0029] The particle size of titanium dioxide is 100 to 200 μm.

[0030] The stabilizer is a mixture of diphenylthiourea and 2-phenylindole with a mass ratio of 1:1.

[0031] The carbonate is sodium carbonate.

[0032] Phthalates are a mixture of diisobutyl phthalate, dimethyl phthalate, and diethyl phthalate in a mass ratio of 1:1:1.

[0033] The preparation method of the above-mentioned modified PET base material for the solar battery back sheet comprises the following steps:

[0034] (1) Mix n-butyl acetate, PET, hexabromocyclododecane, 3-meth...

Embodiment 2

[0040]A modified PET base material for a solar battery back sheet, comprising the following components in parts by weight: 30 parts of n-butyl acetate, 40 parts of PET, 40 parts of hexabromocyclododecane, 3-methyl-2-butene- 30 parts of 1-alcohol, 100 parts of methyl ethyl ketone, 40 parts of titanium dioxide, 20 parts of maleic anhydride grafted polypropylene, 40 parts of stabilizer, 20 parts of carbonate, 30 parts of phthalates.

[0041] The particle size of titanium dioxide is 100 to 200 μm.

[0042] The stabilizer is thiolauric anhydride.

[0043] The carbonate is potassium carbonate.

[0044] Phthalates are a mixture of diethyl phthalate and diisononyl phthalate in a mass ratio of 1:2.

[0045] The preparation method of the above-mentioned modified PET base material for the solar battery back sheet comprises the following steps:

[0046] (1) Mix n-butyl acetate, PET, hexabromocyclododecane, 3-methyl-2-buten-1-ol, titanium dioxide and phthalates evenly, heat to 800-950°C...

Embodiment 3

[0052] A modified PET base material for a solar cell back sheet, comprising the following components in parts by weight: 80 parts of n-butyl acetate, 80 parts of PET, 100 parts of hexabromocyclododecane, 3-methyl-2-butene- 150 parts of 1-alcohol, 200 parts of methyl ethyl ketone, 80 parts of titanium dioxide, 50 parts of maleic anhydride grafted polypropylene, 120 parts of stabilizer, 120 parts of carbonate, 40 parts of phthalates.

[0053] The particle size of titanium dioxide is 100 to 200 μm.

[0054] The stabilizer is a mixture of trimethylolpropane and thiolauric anhydride in a mass ratio of 2:5.

[0055] The carbonate is calcium carbonate.

[0056] The phthalates are diethyl phthalate.

[0057] The preparation method of the above-mentioned modified PET base material for the solar battery back sheet comprises the following steps:

[0058] (1) Mix n-butyl acetate, PET, hexabromocyclododecane, 3-methyl-2-buten-1-ol, titanium dioxide and phthalates evenly, heat to 800-950...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com