Organic electroluminescent material, preparation method and applications thereof

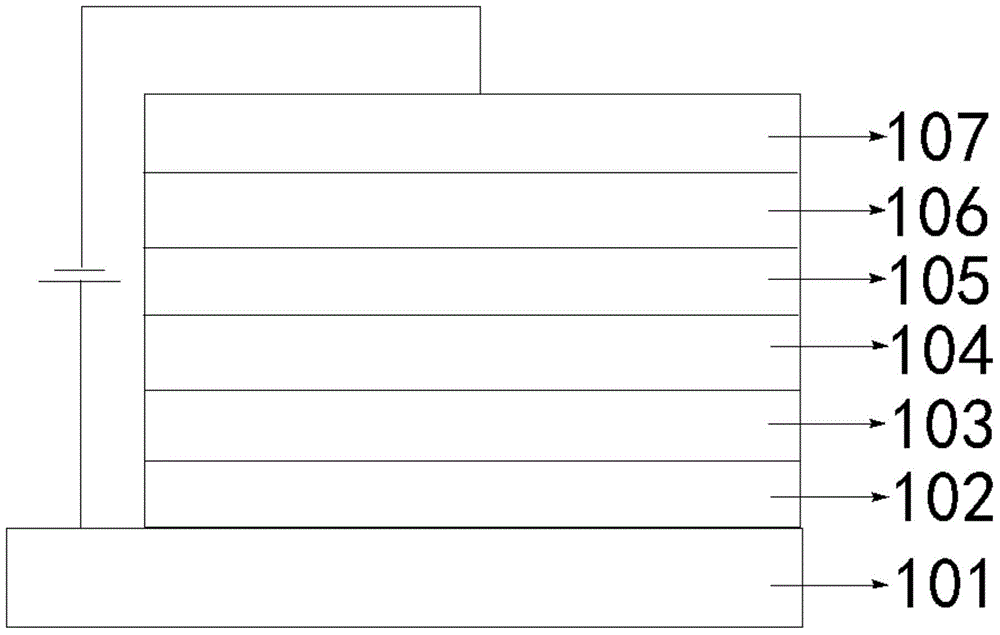

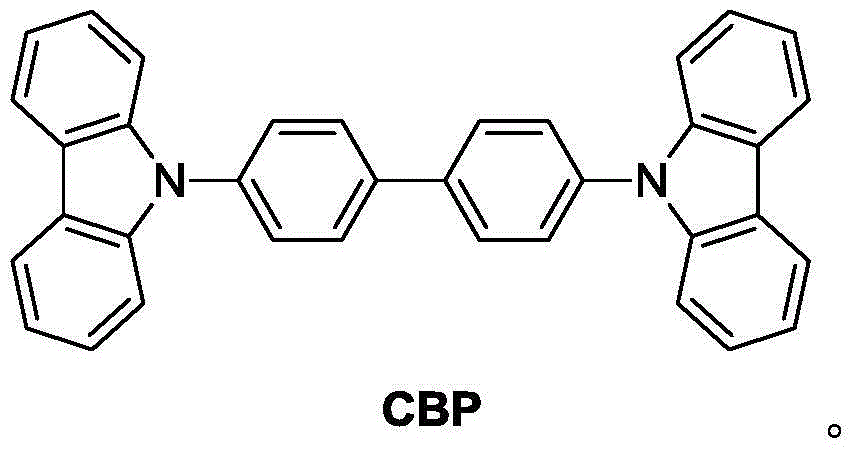

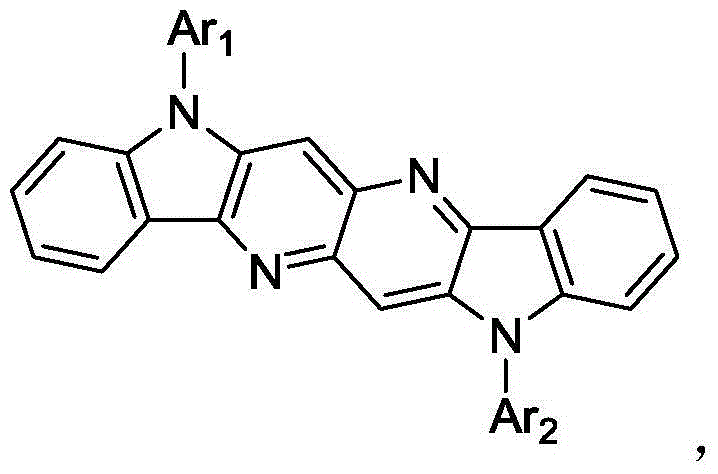

An electroluminescent material and electroluminescent technology, applied in the fields of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve problems such as poor spectral color purity, achieve good current efficiency, low lighting voltage, and reduced lighting voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of compound 1

[0042]

[0043] In a 2L three-necked flask, add 2,6-dibromo-1,5 naphthyridine (80.6g, 0.28mol), 2-nitro-phenylboronic acid ester (154g, 0.62mol), K 2 CO 3 (138g, 1.0mol), toluene (800mL), absolute ethanol (120mL), deionized water (240mL), N 2 protection, adding Pd(PPh 3 ) 4 (8.4g, 0.0072mol), heat up to reflux, keep the temperature for 30h, cool down to room temperature, add 300mL deionized water to the reaction bottle, stir for 5min, separate liquid, wash the organic phase once with 300mL deionized water, collect the organic phase, Anhydrous Na 2 SO4 Dry, filter, remove the solvent, the crude product is purified by silica gel column chromatography, the eluent is ethyl acetate:petroleum ether=1:1, to obtain compound 1, the total weight is 88.2g, the yield is 84.6%, MS (m / s ): 372.3.

Embodiment 2

[0044] Embodiment 2: the preparation of compound 2

[0045]

[0046] In a 2L three-necked flask, add compound 1 (85.6g, 0.23mol), triphenylphosphine (262.2g, 1.0mol), 600mL o-dichlorobenzene, N 2 Protect, heat up to internal temperature 165-170°C, keep warm for 10h, stop heating, cool down to room temperature, remove solvent under reduced pressure, the obtained crude product is purified by silica gel column chromatography, and the eluent is petroleum ether: ethyl acetate = 1: 1. Further recrystallization using methyl ethyl ketone as a solvent to obtain compound 2, brown-yellow crystals, with a total weight of 54.0 g, a yield of 76.2%, and MS (m / s): 308.1.

Embodiment 3

[0047] Embodiment 3: the preparation of compound 3 and compound C01

[0048]

[0049] In a 500mL three-necked flask, add compound 2 (30.8g, 0.10mol), iodobenzene (22.4g, 0.11mol), cuprous iodide (1.9g, 0.01mol), potassium carbonate (27.5g, 0.2mol), DMF (280mL), under the protection of nitrogen, raise the temperature to an internal temperature of 110-115°C, keep it warm for 16 hours, then cool down to room temperature, slowly pour the reaction solution into 1L of deionized water, stir at room temperature for 1 hour, filter with suction, collect the filter cake, and remove it to 400L Wash with ionic water, suction filter, rinse with 100mL methanol, collect the solid, purify by silica gel column chromatography, gradient elution, eluent first use petroleum ether:ethyl acetate=3:1, collect compound C01, slightly yellow Solid 11.2g, yield 24%; then the eluent was replaced with petroleum ether: ethyl acetate = 1:1, compound 3 was collected, light brown solid 18.7g, yield 48.6%, MS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com