A catalytic conversion method for producing ethylene and propylene

A catalytic conversion method and a technology of standby catalysts, which are applied in the production of bulk chemicals, chemical recovery, organic chemistry, etc., can solve the problems of low output of straight-run naphtha, impact on economy, and high local temperature, so as to improve operational stability The effect of overcoming high methane production rate and relieving huge pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

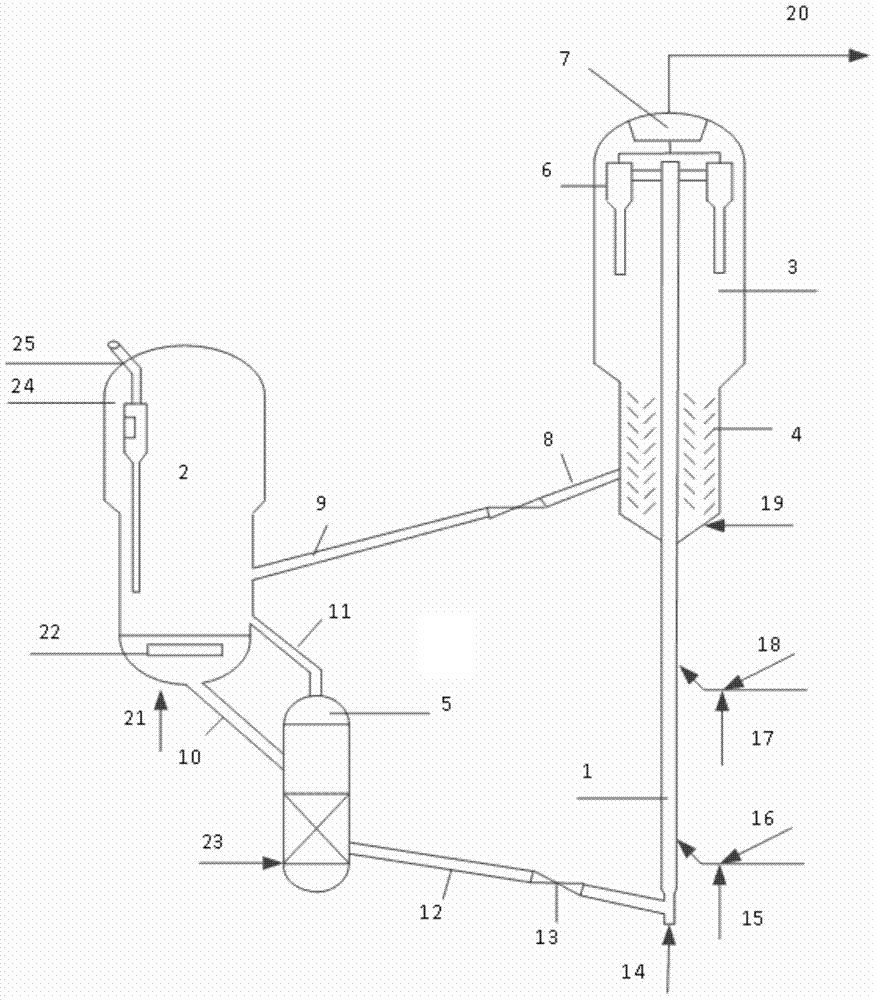

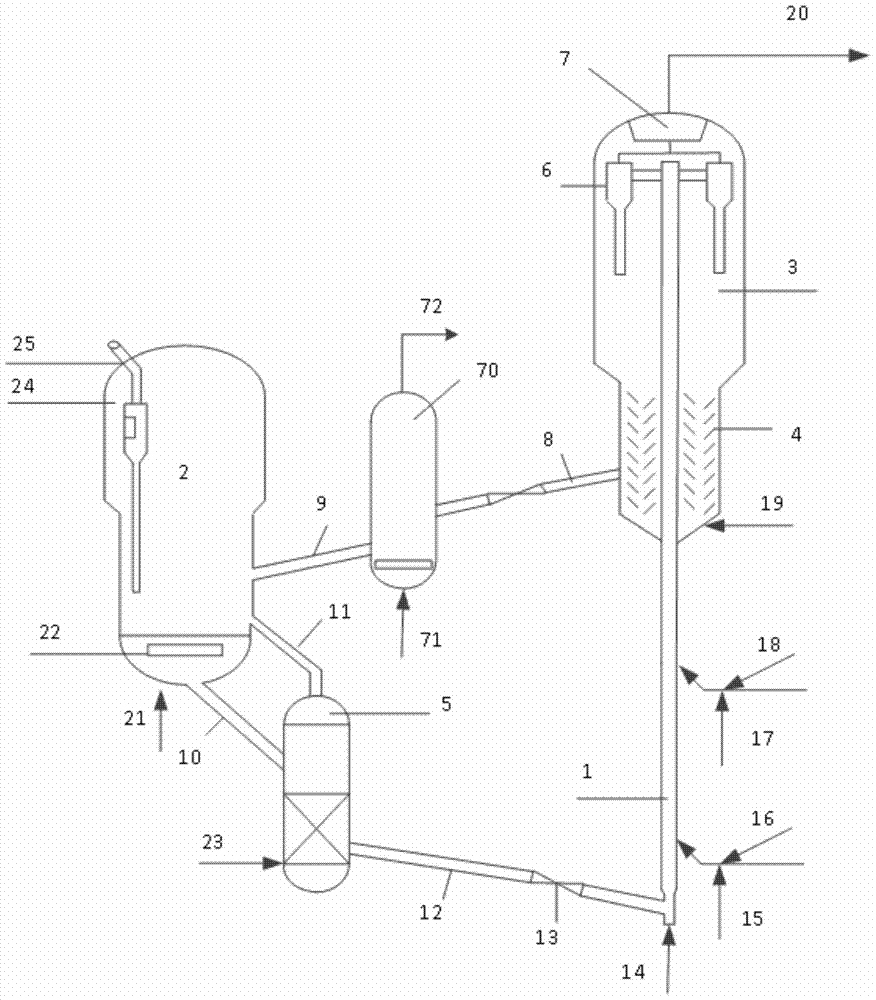

[0074] According to one embodiment of the present invention, when the method of the present invention is carried out in riser reactor, generally carry out as follows:

[0075] The regenerated catalyst (catalytic cracking catalyst) rich in medium pore zeolite enters the pre-lift section of the riser reactor and flows upward under the action of the pre-lift medium. The preheated raw material oil is mixed with part of methane, and the mixture flow is mixed with atomized steam They are injected into the lower part of the riser reactor together, contact with the regenerated catalyst for catalytic cracking reaction and flow upward at the same time; the reacted stream enters the cyclone separator through the outlet of the riser reactor, and the separated reaction oil gas extraction device is further separated to obtain methane, ethylene, Fractions such as propylene, C4 hydrocarbons, and pyrolysis gasoline; part of the methane is returned to the riser reactor, and the separated raw cat...

Embodiment 1

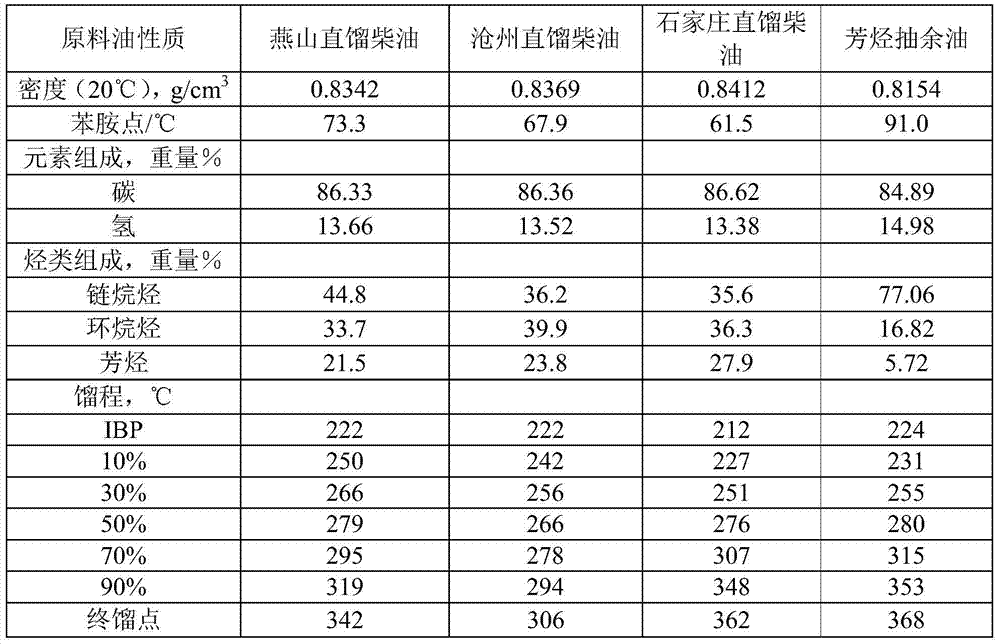

[0094] according to figure 2 The test is carried out on the medium-sized device of the riser reactor. The feedstock oil is Yanshan straight-run diesel oil (properties are shown in Table 1). The preheated feedstock oil is mixed with part of methane and then enters the bottom of the riser (methane and The mass ratio of the raw material oil is 5:100), the cracking reaction is carried out under the conditions of the reaction temperature of 650°C, the reaction time of 1.8 seconds, the weight ratio of the catalytic cracking catalyst to the raw material oil of 15, and the weight ratio of water vapor to the raw material oil of 0.25. The reaction oil gas, water vapor and ungenerated catalyst enter the closed cyclone separator from the outlet of the reactor, the reaction oil gas and the ungenerated catalyst are quickly separated, and the reaction oil gas is cut according to the distillation range in the separation system after exchanging heat with the raw material, so as to obtain metha...

Embodiment 2

[0098] This example follows figure 2 The process of the test is carried out, the raw material oil is Yanshan straight-run diesel oil, and the test is carried out on the medium-sized device of the riser reactor, and the preheated raw material oil is mixed with part of methane and then enters the bottom of the riser (the mass ratio of methane to the raw material oil is 7.5: 100), under the conditions of reaction temperature 630°C, reaction time 2.0 seconds, weight ratio of catalytic cracking catalyst to feedstock oil 18, weight ratio of water vapor to feedstock oil 0.25, the cracking reaction is carried out to react oil gas, water vapor and raw The catalyst enters the closed cyclone separator from the outlet of the reactor, and the reacted oil gas and the unborn catalyst are quickly separated. After heat exchange with the raw material, the reacted oil gas is cut according to the distillation range in the separation system, thereby obtaining four groups of methane, ethylene, prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com