Lithium ion battery anode material and preparation method thereof, and lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of amorphous carbon with large specific surface area, high activity, shedding, and material pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

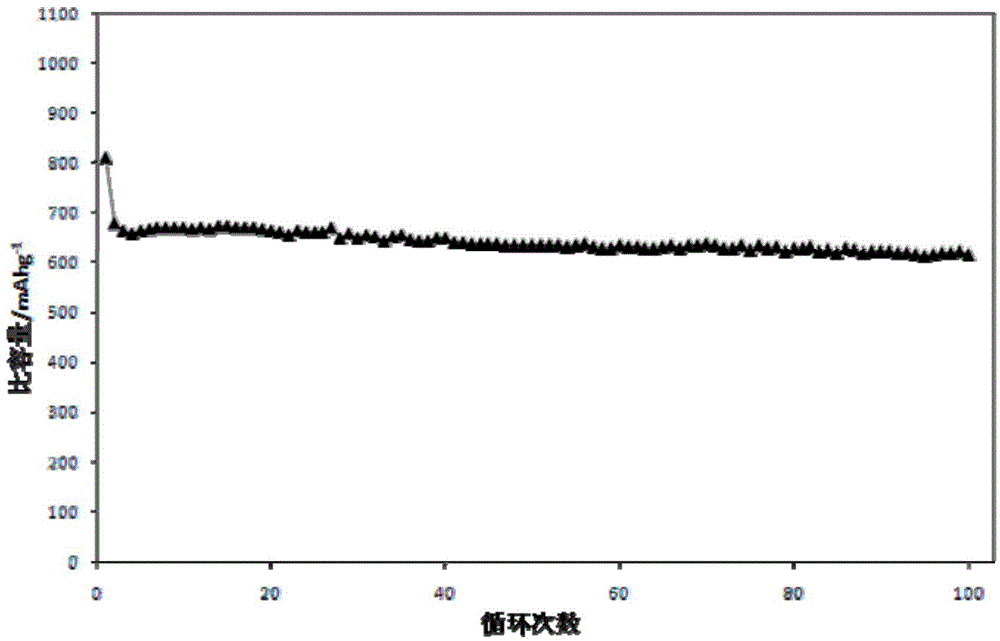

Image

Examples

Embodiment 1

[0022] This embodiment provides a preparation method of lithium ion battery negative electrode material, comprising the following steps:

[0023] (1) Mix aluminum powder and silicon oxide, wherein the particle size of aluminum powder is 5 μm, and the particle size of silicon oxide is 75 μm to obtain a mixture, which includes silicon oxide and aluminum powder, wherein silicon oxide The mass ratio to aluminum powder is 1.2:1. When the mass ratio of the silicon oxide to the aluminum is 1.2:1, the aluminum can fully reduce the active oxygen in the finally prepared lithium ion negative electrode material and improve the first charge and discharge efficiency of the lithium ion negative electrode material.

[0024] (2) Put the mixture obtained in step (1) into a high-temperature furnace with an inert atmosphere, raise the temperature to 900°C at a heating rate of 6°C / min, and burn for 6 hours to obtain the negative electrode material for lithium-ion batteries.

[0025] When silicon ...

Embodiment 2

[0031] This embodiment provides a preparation method of lithium ion battery negative electrode material, comprising the following steps:

[0032] (1) Mix the aluminum powder and silicon oxide, wherein the particle size of the aluminum powder is 10 μm, and the particle size of the silicon oxide is 30 μm, and put it into a planetary ball mill at a speed of 300 rpm for 8 hours to obtain a mixture. In the mixture It includes silicon oxide and aluminum powder, wherein the mass ratio of silicon oxide to aluminum powder is 1.7:1. When the mass ratio of the silicon oxide to the aluminum is 1.7:1, the aluminum can fully reduce the active oxygen in the finally prepared lithium ion negative electrode material, and improve the first-time efficiency of charge and discharge of the lithium ion negative electrode material .

[0033] (2) Put the mixture obtained in step (1) into a high-temperature furnace under vacuum conditions, raise the temperature to 1000°C at a heating rate of 4°C / min, a...

Embodiment 3

[0036] This embodiment provides a preparation method of lithium ion battery negative electrode material, comprising the following steps:

[0037](1) Mix the aluminum powder and silicon oxide, wherein the particle size of the aluminum powder is 1 μm, and the particle size of the silicon oxide is 5 μm, and put it into a planetary ball mill at a speed of 500 rpm for 4 hours to obtain a mixture. It includes silicon oxide and aluminum powder, wherein the mass ratio of silicon oxide to aluminum powder is 2.2:1. When the mass ratio of the silicon oxide to the aluminum is 2.2:1, the aluminum can fully reduce the active oxygen in the finally prepared lithium ion negative electrode material, and improve the first-time efficiency of charge and discharge of the lithium ion negative electrode material .

[0038] (2) Put the mixture obtained in step (1) into a high-temperature furnace with an inert atmosphere. The first stage: heat up from room temperature to 710°C at a heating rate of 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com