Electrolytic aluminium waste gas treatment integrated device

A technology for waste gas treatment and electrolysis of aluminum, which is applied in the field of air pollution control and can solve problems such as waste gas pollution from electrolysis aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

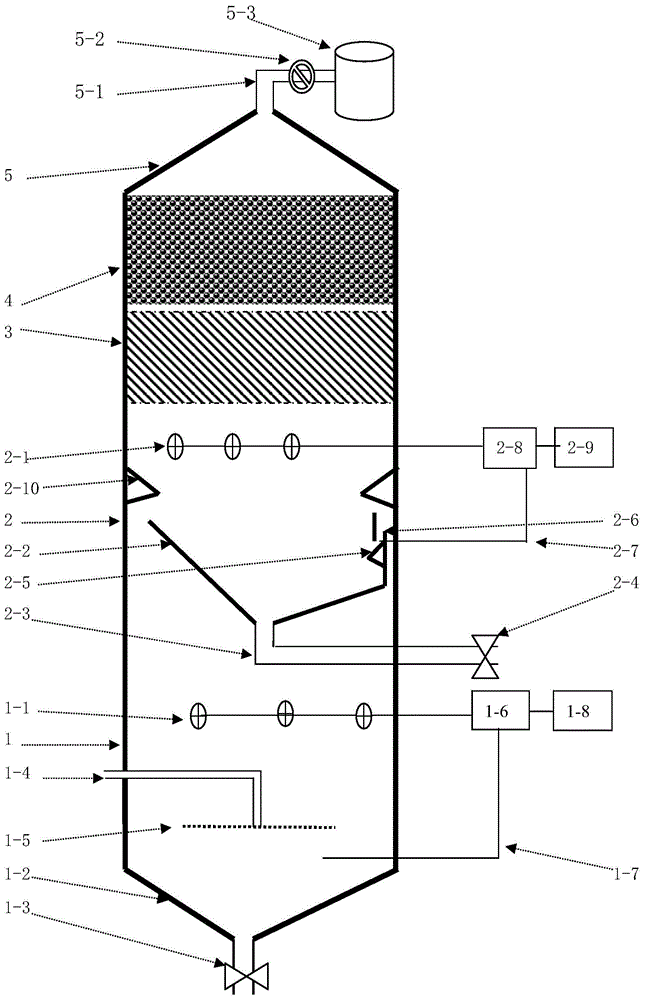

[0027] Such as figure 1 The shown integrated electrolytic aluminum waste gas treatment device of the present invention includes defluorination and dust removal area 1, alkalization absorption area 2, demister 3, drying area 4 and gas collection area 5 from the bottom of the device upwards.

[0028] The defluorination and dust removal area 1 is located at the bottom of the whole device; the defluorination and dust removal area 1 is provided with a defluorination and dust removal assembly, and the defluorination and dust removal assembly includes a defluorination and dust removal liquid located on the upper part of the defluorination and dust removal assembly Spray device 1-1, waste water collection conical tank 1-2 located at the lower part of the defluorination and dust removal assembly, waste water collection conical tank 1-2 is connected to the waste water treatment pool through the waste water discharge valve 1-3 and the pipeline, and the waste water treatment reaches the st...

Embodiment 2

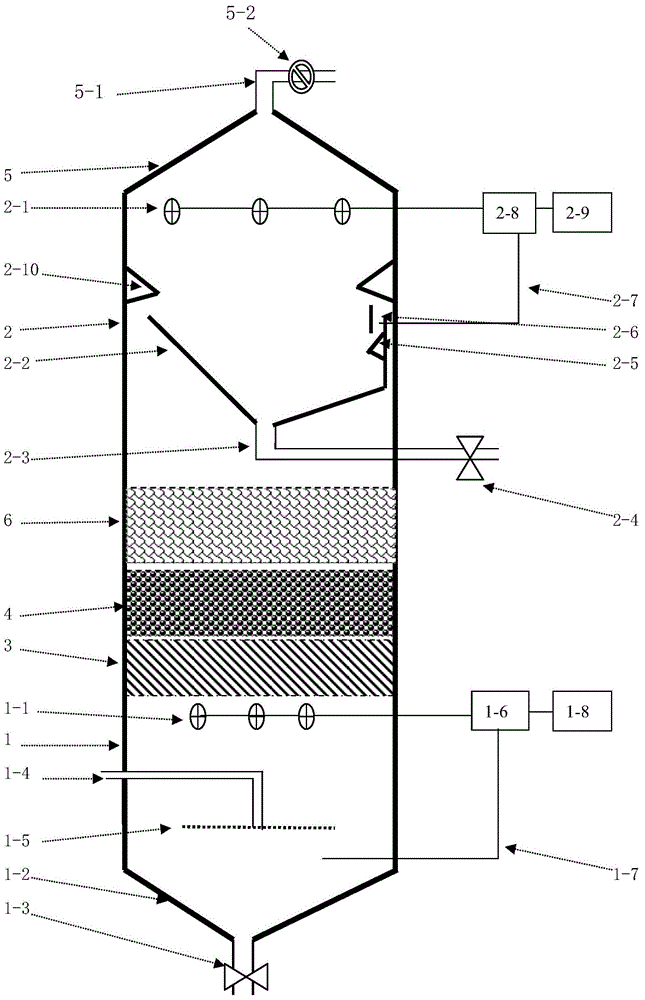

[0043] Such as figure 2 The difference between the electrolytic aluminum waste gas treatment integrated device of the present invention and the embodiment 1 is that the structure of the integrated device is defluorination and dust removal area 1, demister 3, drying area 4, oxidation area from the bottom of the device upwards. Zone 6, alkalization absorption zone 2.

[0044] The oxidation zone 6 is provided with an oxidation component, and the oxidation component includes an electric heating tube and a copper oxide active bed located on the upper part of the electric heating tube, and copper oxide scraps and copper oxide powder are placed on the copper oxide active bed.

[0045] The exhaust gas first enters the defluorination and dust removal area 1, and the defluorination and dust removal liquid is sprayed 1-1 from the uniformly distributed defluorination and dust removal liquid spraying device, forming countless fine mist droplets. After fully mixing and contacting with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com