Preparation method of nano-filtration membrane

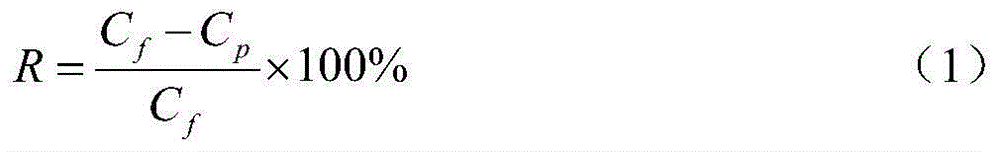

A technology of nanofiltration membrane and ultrafiltration membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of decreased desalination rate, uneven and stable water phase and oil phase solution, and low flux. Achieve the effect of increasing flux, improving retention rate, and cheap and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare 3wt% piperazine solution and stir evenly; prepare 0.08wt% n-hexane solution of polyfunctional acid chloride;

[0025] Fix the polysulfone ultrafiltration membrane with a molecular weight cut-off of about 50,000 on a glass plate, then pour a certain volume of aqueous phase solution on the surface of the membrane, and after standing for 10 seconds, pour off the aqueous phase solution, and the aqueous phase on the membrane surface After drying, pour a certain volume of oil phase solution on the surface of the membrane, place it for 10 seconds, pour off the oil phase, and then evaporate it in an oven at 80°C for 2 minutes to obtain a high-flux sodium filter membrane. The film was soaked in pure water for testing.

Embodiment 2

[0027] Take out the diaphragm in the oven, and immediately immerse it in 30wt%, 50wt% and 100wt% glycerin aqueous solution for 30s respectively, and other operating steps are the same as in Example 1.

Embodiment 3

[0029] Take out the diaphragm in the oven, and immediately immerse in 50 wt% 1,3-propanediol, diethanol, 1,2-propanediol and citric acid in the aqueous solution for 30 seconds respectively, and other operating steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com