Syngas CO combined conversion method and apparatus

A shift device and synthesis gas technology, applied in the field of chemical engineering, can solve the problems of complex reactor structure, weak heat exchange effect, and reduced catalyst strength, and achieve the reduction of treatment process shortening, equipment reduction, catalyst consumption reduction, and equipment investment reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

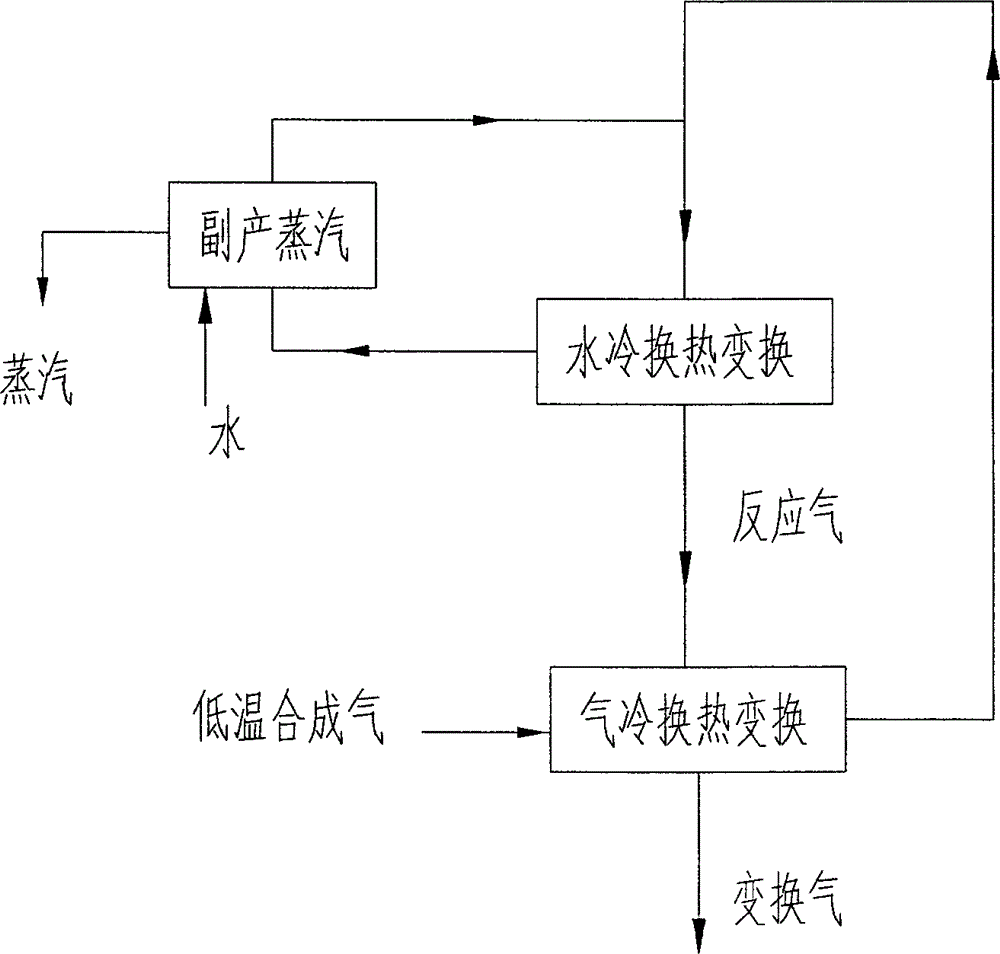

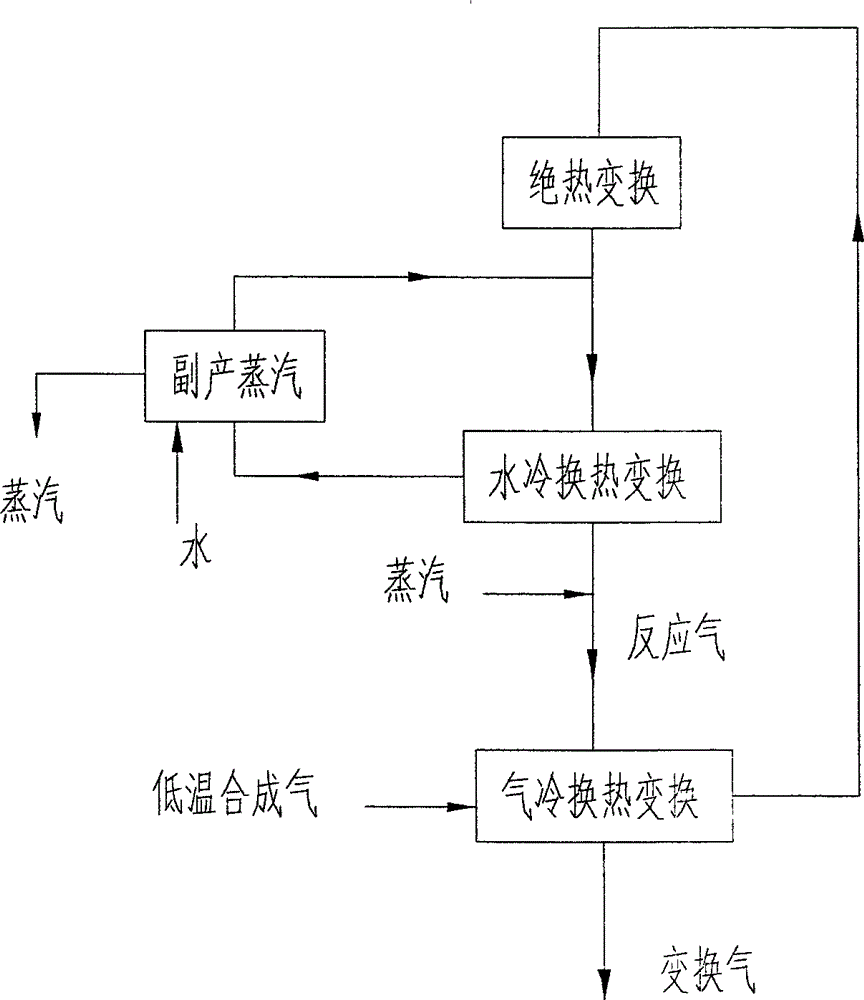

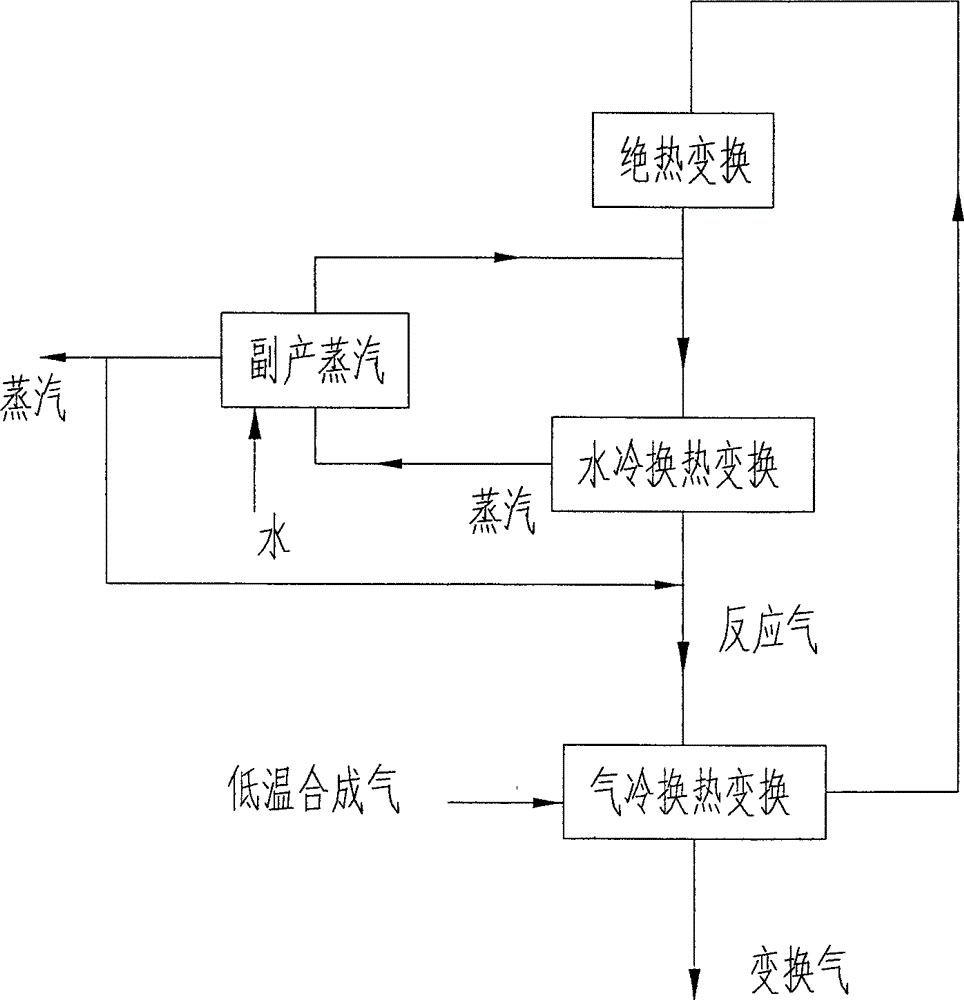

Method used

Image

Examples

Embodiment 1

[0042] use as Figure 8 The shown device comprises a crude gas filter 4, an air-cooled heat transfer shift reactor 1, a pre-shift reactor 5 and a water-cooled heat transfer shift reactor 2 connected in sequence, and the gas outlet of the crude gas filter 4 is connected to the gas The tube-side inlet of the cold heat-exchange shift reactor 1 is connected, the tube-side outlet of the air-cooled heat-exchange shift reactor 1 is connected to the inlet of the pre-shift reactor 5, and the outlet of the pre-shift reactor 5 is connected to the water-cooled heat-exchange shift reactor 2 The shell-side inlet of the water-cooled heat-exchange shift reactor 2 is connected to the shell-side inlet of the air-cooled heat-exchange shift reactor 1, and the two ends of the tube-side of the water-cooled heat-exchange shift reactor 2 are respectively connected Between the inlet and outlet of the drum 3, the steam outlet of the steam drum 3 and the inlet pipeline of the water-cooled heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com