Polypropylene fiber autoclaved aerated concrete and preparation method thereof

A polypropylene fiber, autoclaved aeration technology, used in ceramic products, other household appliances, applications, etc., can solve the problems of easy collapse of buildings and difficult to achieve mechanical strength, and achieve the effect of excellent mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a method for preparing polypropylene fiber autoclaved aerated concrete, the method comprising:

[0015] a, oleic acid, triethanolamine and water are first mixed to make soluble oil;

[0016] b. Aluminum source, foaming agent and water are mixed for the second time to make aluminum powder suspension;

[0017] c, carrying out the third mixing of alkali and water to make alkali solution;

[0018] d. In the presence of a magnetic field with a magnetic field strength of 0.002-0.003T, mix cement, slag, sand, polypropylene fiber, phenolic resin, red brick particles, ferric oxide and water for the fourth time, and then add the Dissolved oil, the alkali solution and the aluminum powder suspension are mixed and poured for the fifth time, and then gas is produced to make polypropylene fiber autoclaved aerated concrete;

[0019] Wherein, the aluminum source is aluminum powder or aluminum paste, the foaming agent is one or more of pull-off powder, Pingpingji...

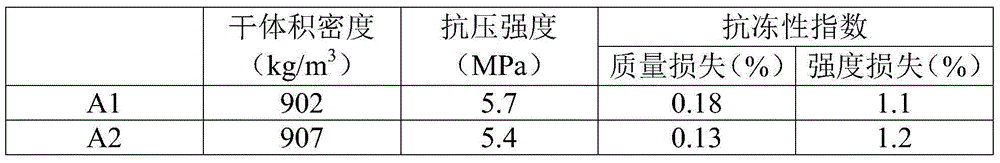

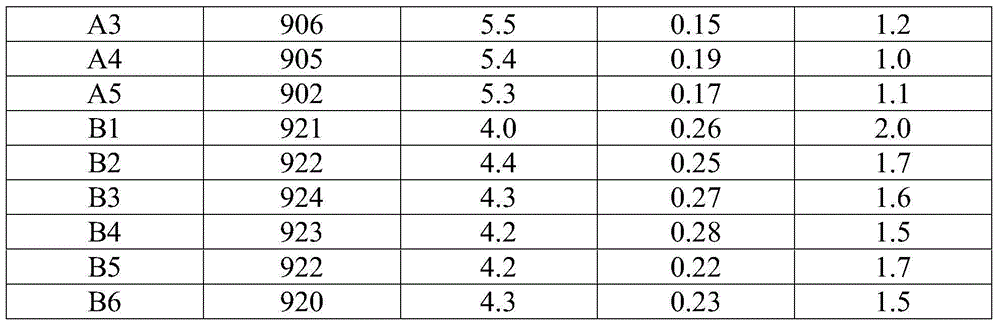

Embodiment 1

[0040] a. At 45°C, mix oleic acid, triethanolamine and water according to the mass ratio of 1:4:35 for the first 40 minutes to make soluble oil;

[0041] b. At 55°C, aluminum powder (with a specific surface area of 5000cm 2 / g), pull open powder and water according to the mass ratio of 1:1:20 for the second mixing for 2 minutes to make aluminum powder suspension;

[0042] c. At 70°C, mix the alkali and water for a third time for 50 minutes to make an alkali solution with a mass fraction of 38%;

[0043] d. In the presence of a magnetic field at 30°C and a magnetic field strength of 0.0025T, mix 100kg of portland cement 425, 170kg of copper slag, 280kg of sand (with a particle size of 5mm), and 15kg of polypropylene fiber (with a length of 5cm) in the presence of a magnetic field of 0.0025T , diameter is 2mm), 6kg phenolic resin (weight average molecular weight is 20000), 9kg red brick particle (particle diameter is 0.02mm), ferric oxide 4kg and water 300kg carry out the thi...

Embodiment 2

[0047] a. At 40°C, mix oleic acid, triethanolamine and water according to the mass ratio of 1:2:30 for the first 30 minutes to make soluble oil;

[0048] b. At 50°C, put aluminum powder (with a specific surface area of 4000cm 2 / g), pull apart powder and water according to the mass ratio of 1:0.8:15 for the second mixing for 1min to make aluminum powder suspension;

[0049] c. At 60°C, carry out the third mixing of alkali and water for 40 minutes to make an alkali solution with a mass fraction of 35%;

[0050] d. In the presence of a magnetic field at 20°C and a magnetic field strength of 0.002T, mix 100kg of Portland cement 425, 150kg of copper slag, 250kg of sand (with a particle size of 4mm), and 10kg of polypropylene fiber (with a length of 3cm) in the presence of a magnetic field of 0.002T. , diameter is 1mm), 5kg phenolic resin (weight-average molecular weight is 14000), 7kg red brick particle (particle diameter is 0.01mm), ferric oxide 3kg and water 250kg carry out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com