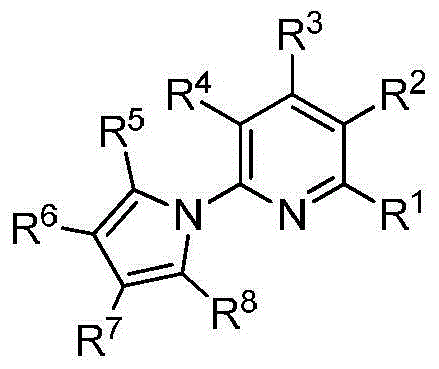

Polysubstituted 2-pyrrolopyridine derivative and preparation method thereof

A technology of pyrrole pyridine and multi-substitution, which is applied in the field of multi-substituted 2-pyrrole pyridine derivatives and its preparation, can solve the problems of difficulty in synthesizing multi-substituted 2-pyrrole pyridine derivatives, metal residues in products, limited use, etc., and achieve The effect of strong reaction specificity, mild reaction conditions and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

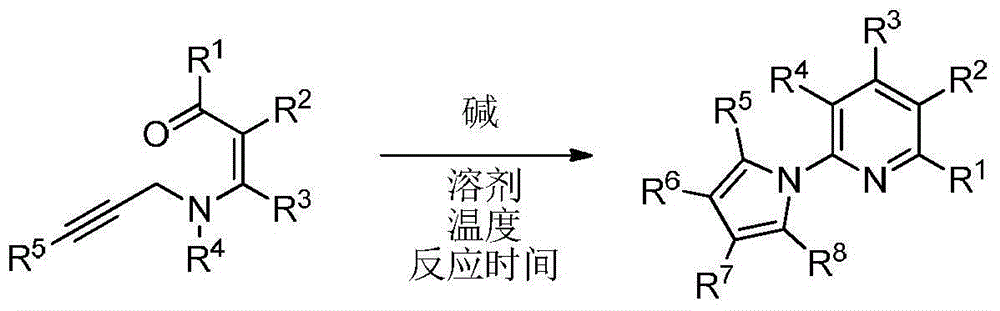

Method used

Image

Examples

Embodiment 1

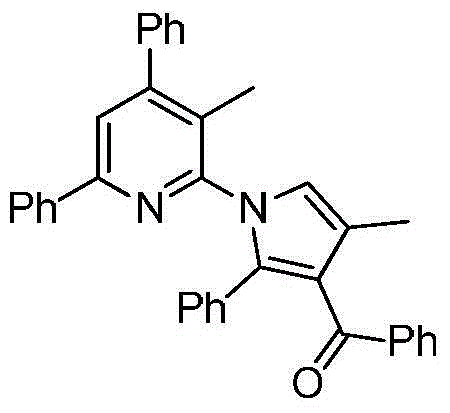

[0023] Preparation of 2-(3-benzoyl-2-phenyl-4-methylpyrrole-1-)-4,6-diphenyl-3-methylpyridine

[0024]

[0025] Add 0.5mmol of 1,3-diphenyl-3-(prop-2-yne-1-amino)prop-2-en-1-one, 1mmol of potassium hydroxide, and 1.5mL of acetonitrile into a 10mL reaction tube, and place In an oil bath at 120°C, react for 0.5h. Stop the reaction and cool to room temperature. The reaction solution was diluted with ethyl acetate, washed three times with water, and the organic phase was washed with anhydrous Na 2 SO 4 Dried, filtered, concentrated, and purified by column chromatography to obtain 114.7 mg of the target product with a yield of 91%. The NMR characterization of this compound is as follows: 1 H NMR (400MHz, CDCl 3 )δ8.03(d,J=7.4Hz,2H),7.50–7.41(m,4H),7.24(dd,J=7.9,3.1Hz,2H),7.21–7.13(m,2H),7.03–6.84 (m,9H),6.82(d,J=7.4Hz,1H),2.43(s,3H),2.31(s,3H),1.41(s,3H),0.86(d,J=6.8Hz,3H) . 13 C NMR (101MHz, CDCl3) δ196.0, 154.0, 153.3, 151.3, 140.4, 139., 138.4, 138.1, 136.8, 135.0, 13...

Embodiment 2

[0027] Preparation of 2-(3-o-tolyl-2-phenyl-4-methylpyrrole-1-)-4-o-tolyl-6-phenyl-3-methylpyridine

[0028]

[0029] Add 0.5mmol of 1-o-tolyl-3-phenyl-3-(prop-2-yne-1-amino)prop-2-en-1-one, 1mmol of NaOH, and 5mL of acetonitrile into a 10mL reaction tube, and place In an oil bath at 80°C, react for 0.5h. Stop the reaction and cool to room temperature. The reaction solution was diluted with ethyl acetate, washed three times with water, and the organic phase was washed with anhydrous Na 2 SO 4 Dry, filter, concentrate, and purify by column chromatography to obtain 103.7 mg of the target product with a yield of 78%. The NMR characterization of this compound is as follows: 1 H NMR (400MHz, CDCl 3 )δ8.03(d,J=7.4Hz,2H),7.50–7.41(m,4H),7.24(dd,J=7.9,3.1Hz,2H),7.21–7.13(m,2H),7.03–6.84 (m,9H),6.82(d,J=7.4Hz,1H),2.43(s,3H),2.31(s,3H),1.41(s,3H),0.86(d,J=6.8Hz,3H) ; 13 C NMR (101MHz, CDCl 3 )δ196.0, 154.0, 153.3, 151.3, 140.4, 139., 138.4, 138.1, 136.8, 135.0, 131.3, 130.3,...

Embodiment 3

[0031] Preparation of 2-(3-p-tolyl-2-phenyl-4-methylpyrrole-1-)-4-p-tolyl-6-phenyl-3-methylpyridine

[0032]

[0033] Add 0.5mmol of 1-p-tolyl-3-phenyl-3-(prop-2-yne-1-amino)prop-2-en-1-one, 1mmol of potassium tert-butoxide and 3mL of dimethylsulfoxide to 10mL In a reaction tube, placed in an oil bath at 50°C, reacted for 1 h. Stop the reaction and cool to room temperature. The reaction solution was diluted with ethyl acetate, washed three times with water, and the organic phase was washed with anhydrous Na 2 SO 4 Dry, filter, concentrate, and purify by column chromatography to obtain 66.2 mg of the target product with a yield of 49%. The NMR characterization of this compound is as follows: 1 H NMR (400MHz, CDCl 3 )δ8.02(d, J=7.7Hz, 2H), 7.60(d, J=7.5Hz, 3H), 7.46(dt, J=14.4, 7.1Hz, 3H), 7.17(d, J=7.9Hz, 2H), 7.06–6.88(m,10H), 2.36(s,3H), 2.27(s,3H), 2.23(s,3H), 1.59(s,3H); 13 C NMR (100MHz, CDCl 3 )δ1945,154.0,153.1,151.9,142.1,138.3,138.1,137.0,136.6,135.9,131.7,1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com