High cis-1,4 content epoxy hydroxyl-terminated polybutadiene liquid rubber and preparation method thereof

A technology of hydroxyl-terminated polybutadiene and aldehyde-terminated polybutadiene, which is applied in the field of epoxidized hydroxyl-terminated polybutadiene liquid rubber with high cis-1,4 content and its preparation, can solve the problem that is difficult to achieve The microstructure of hydroxyl-terminated polybutadiene, the inability to prepare, and the inability to prepare high-cis forms have achieved the effects of simple and efficient process, wide industrial application prospects, and high reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

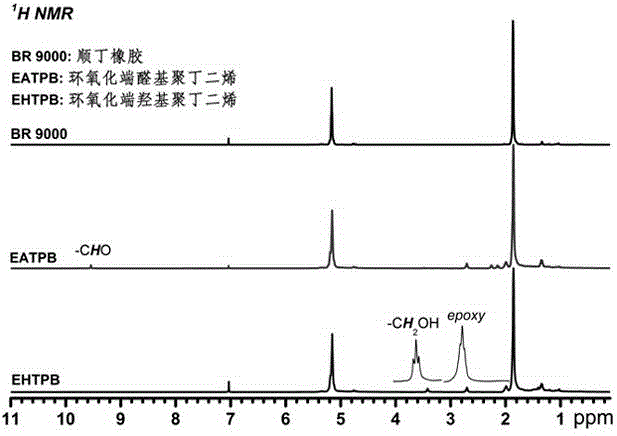

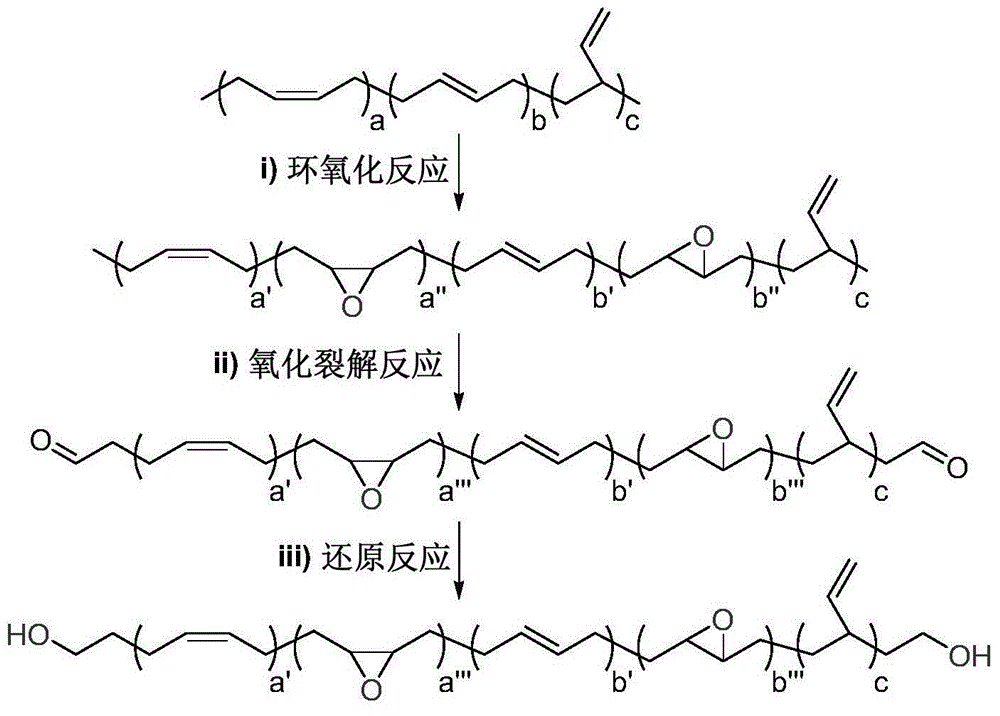

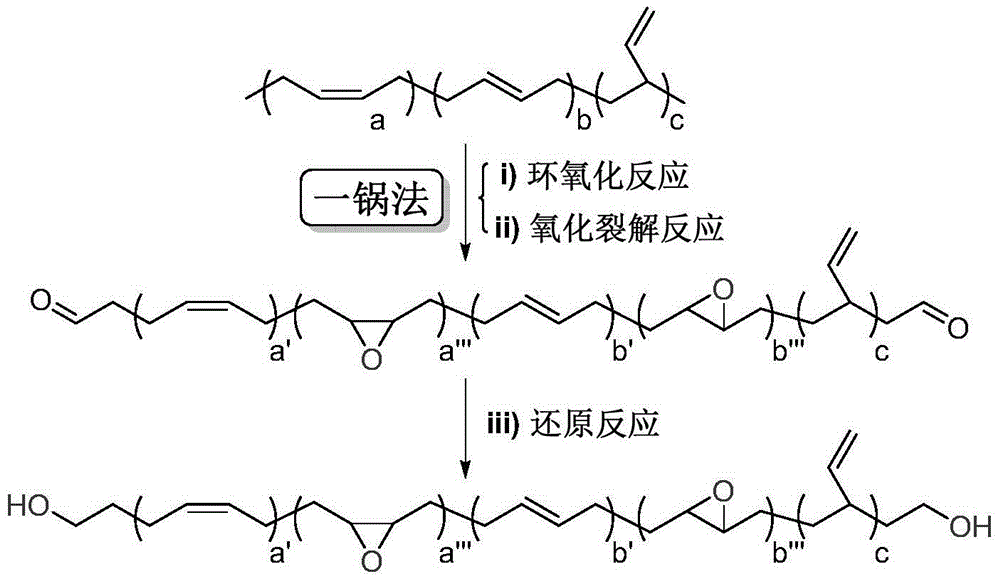

[0050] Take 5.00g of nickel-based butadiene rubber (BR 9000), dissolve it completely in 100mL of tetrahydrofuran, the rubber concentration is 50g / L, keep the temperature at 30°C, add m-chloroperoxybenzoic acid under vigorous stirring, the amount of m-chloroperoxybenzoic acid It is 2% of the butadiene structural unit in nickel-based butadiene rubber (BR 9000), and the reaction time is 6 hours. The product is precipitated with a large amount of ethanol and dried in vacuum. product by 1 H NMR showed that the epoxy content was 2.0%.

[0051] Take 4.00g of the above-mentioned epoxidized butadiene rubber, completely dissolve it in 100mL of tetrahydrofuran, the rubber concentration is 40g / L, keep the temperature at 30°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group is 1 :2, reacted for 30 minutes. The product can be filtered to obtain high cis-1,4 content epoxidized terminal aldehyde polybutadiene liquid rubber, and the product is passe...

Embodiment 2

[0054] Take 5.00g of cobalt-based butadiene rubber (Taipol), dissolve it completely in 200mL of cyclohexane, the rubber concentration is 25g / L, keep the temperature at 50°C, add m-chloroperoxybenzoic acid and m-chloroperoxybenzoic acid under vigorous stirring The dosage is 4% of the butadiene structural unit in cobalt-based butadiene rubber (Taipol), the reaction time is 4 hours, and the product is precipitated with a large amount of ethanol and dried in vacuum. product by 1 H NMR showed that the epoxy content was 4.0%.

[0055] Take 4.00g of the above-mentioned epoxidized butadiene rubber, completely dissolve it in 100mL cyclohexane, the rubber concentration is 40g / L, keep the temperature at 50°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group The ratio is 1:4, and the reaction time is 40 minutes. The product can be filtered to obtain high cis-1,4 content epoxidized aldehyde-terminated polybutadiene liquid rubber, and the epoxy rate...

Embodiment 3

[0058] Take 5.00g of neodymium-based butadiene rubber (BR 9100), dissolve it completely in 100mL of toluene, the rubber concentration is 50g / L, keep the temperature at 70°C, and add (1S,2S)-(+)-[1,2 -Cyclohexanediamine nitrogen-N,N'-bis(3,5-di-tert-butylsalicylidene)]manganese(III) chloride 0.005g, the amount of sodium hypochlorite is neodymium-based butadiene rubber (BR 9100) 8% of the structural unit of butadiene, the reaction time is 2 hours, the product is precipitated with a large amount of ethanol and dried in vacuum. product by 1 H NMR showed that the epoxy rate was 8.0%.

[0059] Take 4.00g of the above epoxidized butadiene rubber, completely dissolve it in 100mL of toluene, the rubber concentration is 40g / L, keep the temperature at 50°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group is 1 :8, reacted in 50 minutes. The product can be filtered to obtain high cis-1,4 content epoxidized terminal aldehyde polybutadiene liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com