Method for preparing nitrogen and sulfur-doped fluorescent carbon quantum dots

A technology of carbon quantum dots and nitrogen sulfur, which is applied in the field of preparation of fluorescent carbon quantum dots, can solve the problems that limit the large-scale production and practical application of fluorescent carbon quantum dots, the cumbersome synthesis process, and the high cost of synthesis, so as to achieve easy promotion and large-scale The production and preparation process equipment is simple and the effect of low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

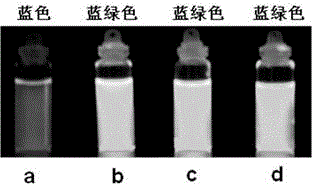

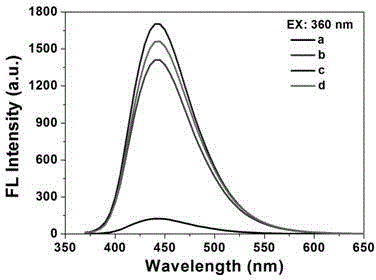

[0026] (1) Put 0.6 g of citric acid and 0.2 g of L-glutathione powder into an agate mortar and grind to obtain a uniform white powder;

[0027] (2) Put the above-mentioned white powder into a microwave oven, use 700 W power, and microwave for 1.5 min to obtain a white carbon quantum dot solid;

[0028] (3) Dissolve the white solid obtained in (2) into 5 mL of water, and ultrasonically obtain a uniform carbon quantum dot solution;

[0029] (4) The solution obtained in step (3) was injected into a dialysis bag for dialysis, the molecular weight cut-off was 500 D, the dialysis time was 48 h, and the water was changed every 6 h;

[0030] (5) The dialysis product is evaporated to obtain a concentrated solution;

[0031] (6) Freeze-dry the concentrated solution at –50 °C to powder to obtain nitrogen-sulfur-doped carbon quantum dots with a yield of about 2% and a quantum yield of about 4.5%.

Embodiment 2

[0033] (1) Put 0.6 g of citric acid and 0.2 g of L-glutathione powder into an agate mortar and grind to obtain a uniform white powder;

[0034] (2) Put the above-mentioned white powder into a microwave oven, adopt 700 W power, microwave radiation for 2 min, and obtain brown carbon quantum dot solid;

[0035] (3) Dissolve the brown solid obtained in (2) into 5 mL of water, and ultrasonically obtain a uniform carbon quantum dot solution;

[0036] (4) The solution obtained in step (3) was injected into a dialysis bag for dialysis, the molecular weight cut-off was 500 D, the dialysis time was 48 h, and the water was changed every 6 h;

[0037] (5) The dialysis product is evaporated to obtain a concentrated solution;

[0038] (6) Freeze-dry the concentrated solution at –50 °C to powder to obtain nitrogen-sulfur-doped carbon quantum dots with a yield of about 12% and a quantum yield of about 50%.

Embodiment 3

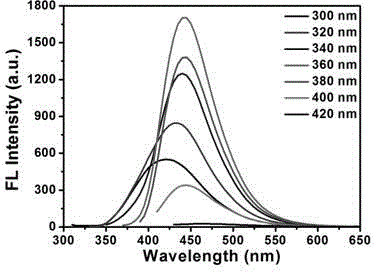

[0040] (1) Put 0.6 g of citric acid and 0.2 g of L-glutathione powder into an agate mortar and grind to obtain a uniform white powder;

[0041] (2) Put the above-mentioned white powder into a microwave oven, use 700 W power, and microwave for 2.5 minutes to obtain a reddish-brown carbon quantum dot solid;

[0042] (3) Dissolve the reddish-brown solid obtained in (2) into 5 mL of water, and ultrasonically obtain a uniform carbon quantum dot solution;

[0043] (4) The solution obtained in step (3) was injected into a dialysis bag for dialysis, the molecular weight cut-off was 500 D, the dialysis time was 48 h, and the water was changed every 6 h;

[0044] (5) The dialysis product is evaporated to obtain a concentrated solution;

[0045] (6) The concentrated solution was freeze-dried at –50 °C to powder to obtain nitrogen-sulfur-doped carbon quantum dots with a yield of about 15% and a quantum yield of about 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com