Preparation method of fragrant capsules

A fragrance and capsule technology, which is applied in the field of preparation of intelligent fragrance capsules, can solve problems that have not been reported, achieve great application prospects and prolong the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of intelligent essence microcapsules, comprising the steps of:

[0020] (1) Weigh 100g of hexadecyl acrylate and 2g of azobisisobutyronitrile and mix evenly, pour into 500g of polyvinyl alcohol solution with a concentration of 2wt%, stir and mix evenly to obtain a uniform and stable solution. After raising the temperature to 80° C. and reacting for 3 hours, polylauryl acrylate particles were obtained, which were washed and dried for use.

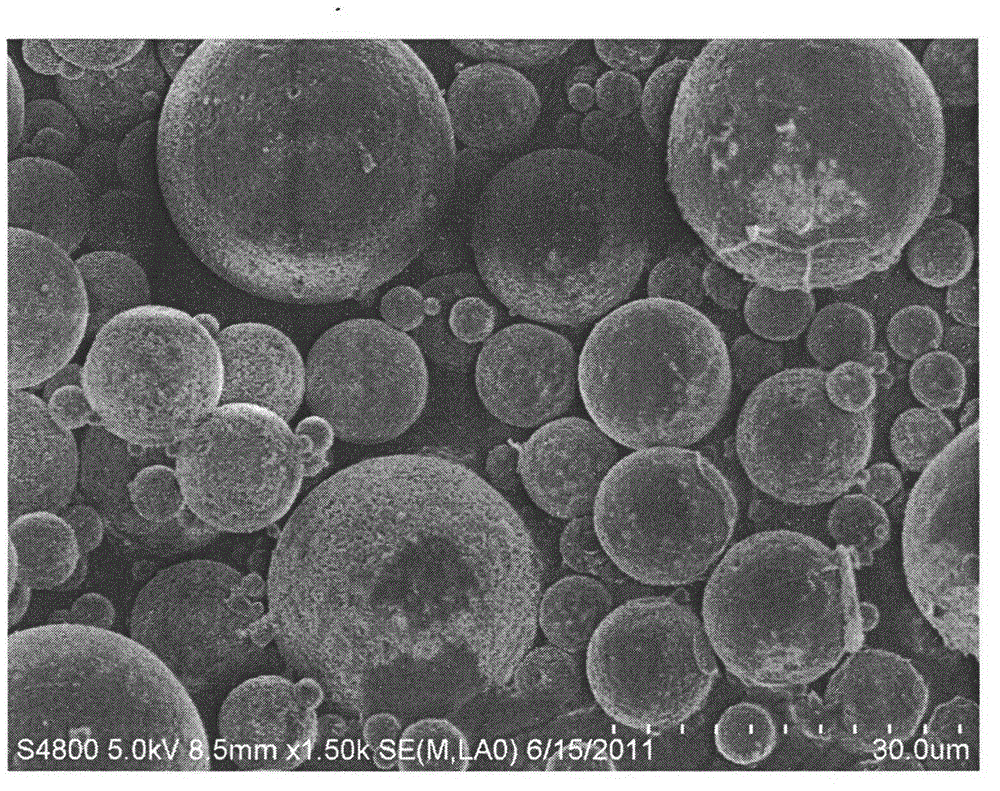

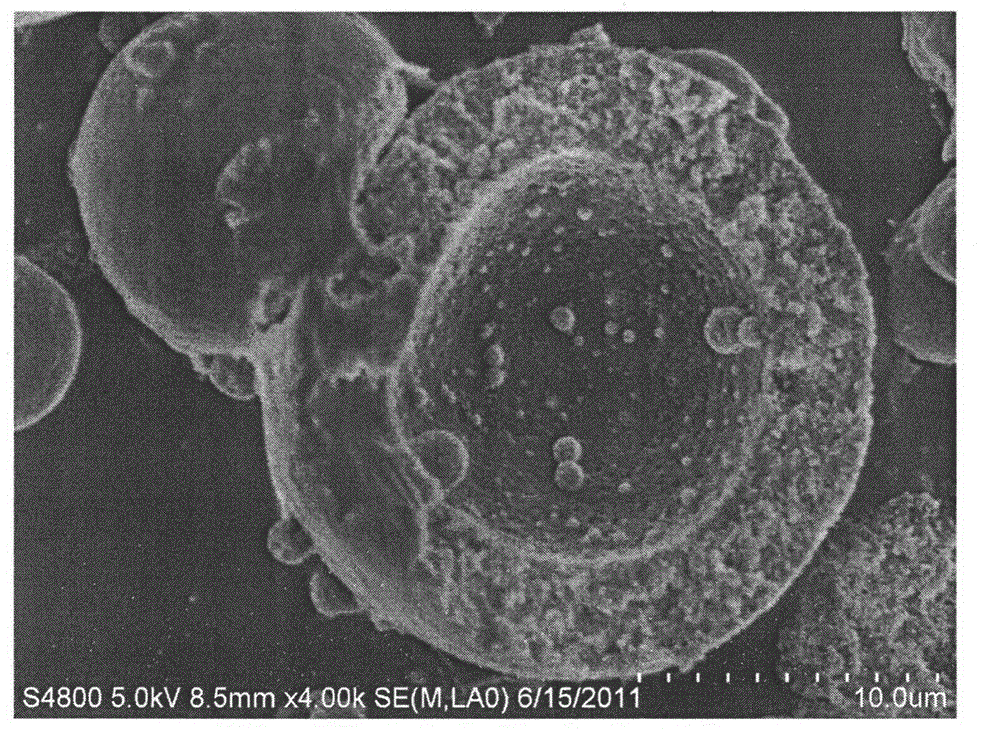

[0021] (2) 80 g of polyhexadecyl acrylate particles and 80 g of cypress essential oil essence were dissolved in 100 g of dichloromethane to obtain a uniform oil phase solution. Disperse the oil phase solution in 1000g of 5wt% polyvinyl alcohol aqueous solution, vigorously stir and emulsify to obtain a stable emulsion with an average particle diameter of about 20 microns.

[0022] (3) Gradually raise the temperature of the stable emulsion obtained in step (2) to 40° C., and continue stirring for 5 hours to remove ...

Embodiment 2

[0025] A preparation method of intelligent essence microcapsules, comprising the steps of:

[0026] (1) After weighing 1Kg of octadecyl methacrylate and 1g of azobisisoheptanonitrile and mixing uniformly, pour 5Kg concentration into 5wt% sodium lauryl sulfate solution and fully stir and mix uniformly to obtain a uniform stable solution . After heating up to 60°C, react for 3 hours to obtain polyoctadecyl methacrylate particles, which are washed and dried for use.

[0027] (2) 500 g of polyhexadecyl acrylate particles and 10 g of synthetic musk were dissolved in 500 g of ethyl acetate to obtain a uniform oil phase solution. Disperse the oil phase solution in 5kg of 5wt% styrene maleic anhydride aqueous solution, vigorously stir and emulsify to obtain a stable emulsion with an average particle diameter of about 5 microns.

[0028] (3) Gradually raise the temperature of the stable emulsion obtained in step (2) to 78° C., and continue stirring for 5 hours to remove ethyl acetate...

Embodiment 3

[0030] A preparation method of intelligent essence microcapsules, comprising the steps of:

[0031] (1) After weighing 500 g of behenyl acrylate and 10 g of benzoyl peroxide and mixing them uniformly, pour them into 2.5 kg of 2 wt % sodium alginate solution, stir and mix evenly to obtain a uniform and stable solution. After raising the temperature to 85° C. and reacting for 4.5 hours, polybehenyl acrylate particles were obtained, which were washed and dried for use.

[0032] (2) 350 g of polybehenyl acrylate particles and 3.5 kg of rose essential oil essence were dissolved in 500 g of 1,2-dichloroethane to prepare a uniform oil phase solution. Disperse the oil phase solution in 5kg of 5wt% gelatin aqueous solution, emulsify with vigorous stirring, and obtain a stable emulsion with an average particle diameter of about 80 microns.

[0033] (3) Gradually raise the temperature of the stable emulsion obtained in step (2) to 68° C., and continue stirring for 12 hours to remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com