Microcapsule capable of cladding 2,4-dichloro-3,5-dimethylphenol, as well as preparation and application of microcapsule

A technology of dimethylphenol and microcapsules, which is applied to microcapsule materials and the fields of preparation and application thereof, can solve problems such as human discomfort, achieve long-term antibacterial and antifungal properties, and maintain the effects of antibacterial and antifungal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

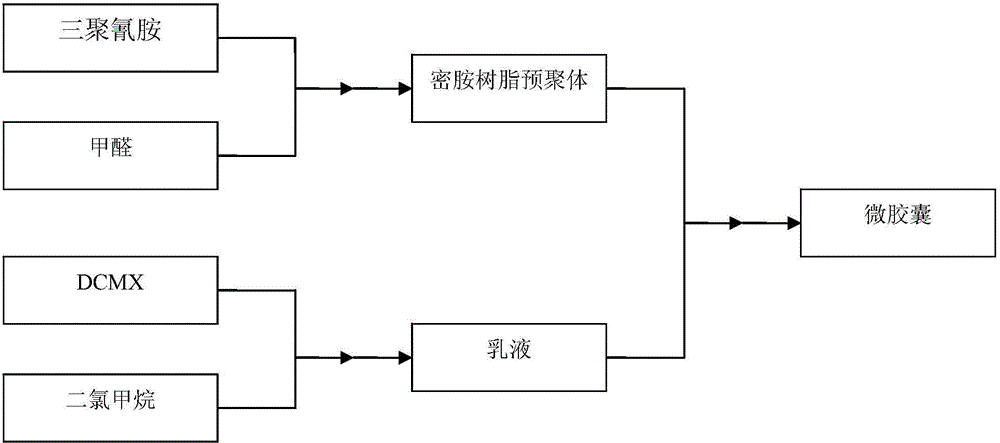

[0036] a. Preparation of Microcapsules

[0037] (1) Core material preparation

[0038] Weigh 1g of DCMX into a three-necked flask, pour 5ml of dichloromethane into it, fully dissolve, add 91ml of distilled water, 4ml of Tween 80 and 0.5ml of Span 80, and stir and emulsify at 1800r / min for 30min at room temperature.

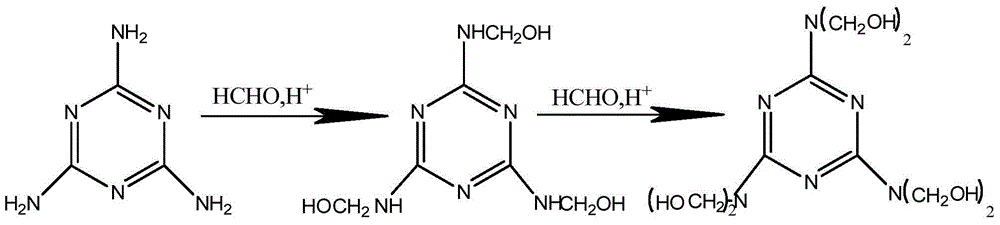

[0039] (2) Wall material preparation

[0040] Weigh 1.75g of melamine into a sealable reagent bottle, pipette 3.00ml of 37% formaldehyde solution into the reagent bottle, mix, stir evenly with a magnetic force, add 10% NaOH solution to adjust the pH to 8~9, and then put it in a water bath at 65°C~70°C Heating, after reacting until transparent, add 10ml of distilled water, and continue to react for 50min to obtain a transparent low molecular weight prepolymer.

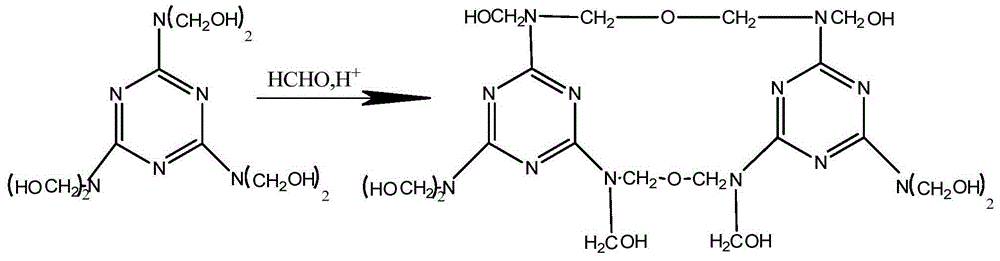

[0041] (3) Preparation of microcapsules

[0042] Add the obtained prepolymer into the core material emulsion, drop a few drops of defoamer to defoam, stir at 450r / min for 20min, add 10% citric acid dro...

Embodiment 2

[0050] a. Preparation of Microcapsules

[0051] (1) Core material preparation

[0052] Weigh 1g of DCMX into a three-necked flask, pour 6ml of dichloromethane into it, fully dissolve, add 90ml of distilled water, 4ml of Tween 80 and 0.5ml of Span 80, and stir and emulsify at 1800r / min for 30min at room temperature.

[0053] (2) Wall material preparation

[0054] Weigh 1.75g of melamine into a sealable reagent bottle, pipette 3.50ml of 37% formaldehyde solution into the reagent bottle, mix, stir evenly with a magnetic force, add 10% NaOH solution to adjust the pH to 8-9, heat in a water bath at 65°C to 70°C, After the reaction was transparent, 10ml of distilled water was added, and the reaction was continued for 50 minutes to obtain a transparent low molecular weight prepolymer.

[0055] (3) Preparation of microcapsules

[0056] Add the obtained prepolymer into the core material emulsion, drop a few drops of defoamer to defoam, stir at 450r / min for 20min, add 10% citric ac...

Embodiment 3

[0064] a. Preparation of Microcapsules

[0065] (1) Core material preparation

[0066] Weigh 1g of DCMX into a three-necked flask, pour 6ml of dichloromethane into it, fully dissolve, add 90ml of distilled water, 4ml of Tween 80 and 0.5ml of Span 80, stir at 2000r / min at room temperature, and emulsify for 25min.

[0067] (2) Wall material preparation

[0068] Weigh 2g of melamine into a sealable reagent bottle, pipette 3.00ml of 37% formaldehyde solution into the reagent bottle, mix, stir evenly with a magnetic force, add 10% NaOH solution to adjust the pH to 8-9, then heat in a water bath at 65°C to 70°C, After the reaction was transparent, 10ml of distilled water was added, and the reaction was continued for 40 minutes to obtain a transparent low molecular weight prepolymer.

[0069] (3) Preparation of microcapsules

[0070] Add the obtained prepolymer into the core material emulsion, drop a few drops of defoamer to defoam, stir at 500r / min for 20min, add 10% citric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com