Building powder coating with mildew resistance

A powder coating and construction technology, applied in the field of architectural powder coatings, can solve the problems that the coating is easy to breed bacteria and mold, does not have antibacterial and antifungal properties, and affects people's quality of life, so as to maintain antibacterial and antifungal properties and long-term antibacterial and antifungal properties. , the effect of stabilizing the dielectric constant and dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material source:

[0034] 2-(2-Benzothiazole) ethyl acetate: CAS number: 29182-42-1; purchase source: Shanghai Xianding Biotechnology Co., Ltd.;

[0035] Aminoethylaminopropyldimethoxysilane: CAS number: 3069-29-2; purchase source: Bailingwei Technology Co., Ltd.;

[0036] 1,2-Epoxy-9-decene: CAS number: 85721-25-1; purchase source: Shanghai Xianding Biotechnology Co., Ltd.

[0037] The preparation method of mildew-resistant modifier is:

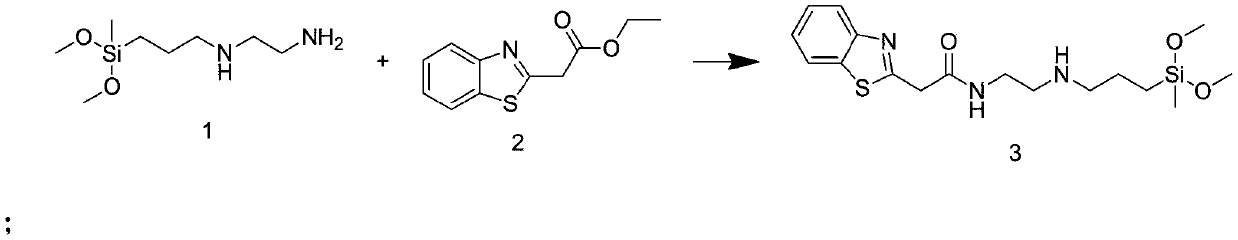

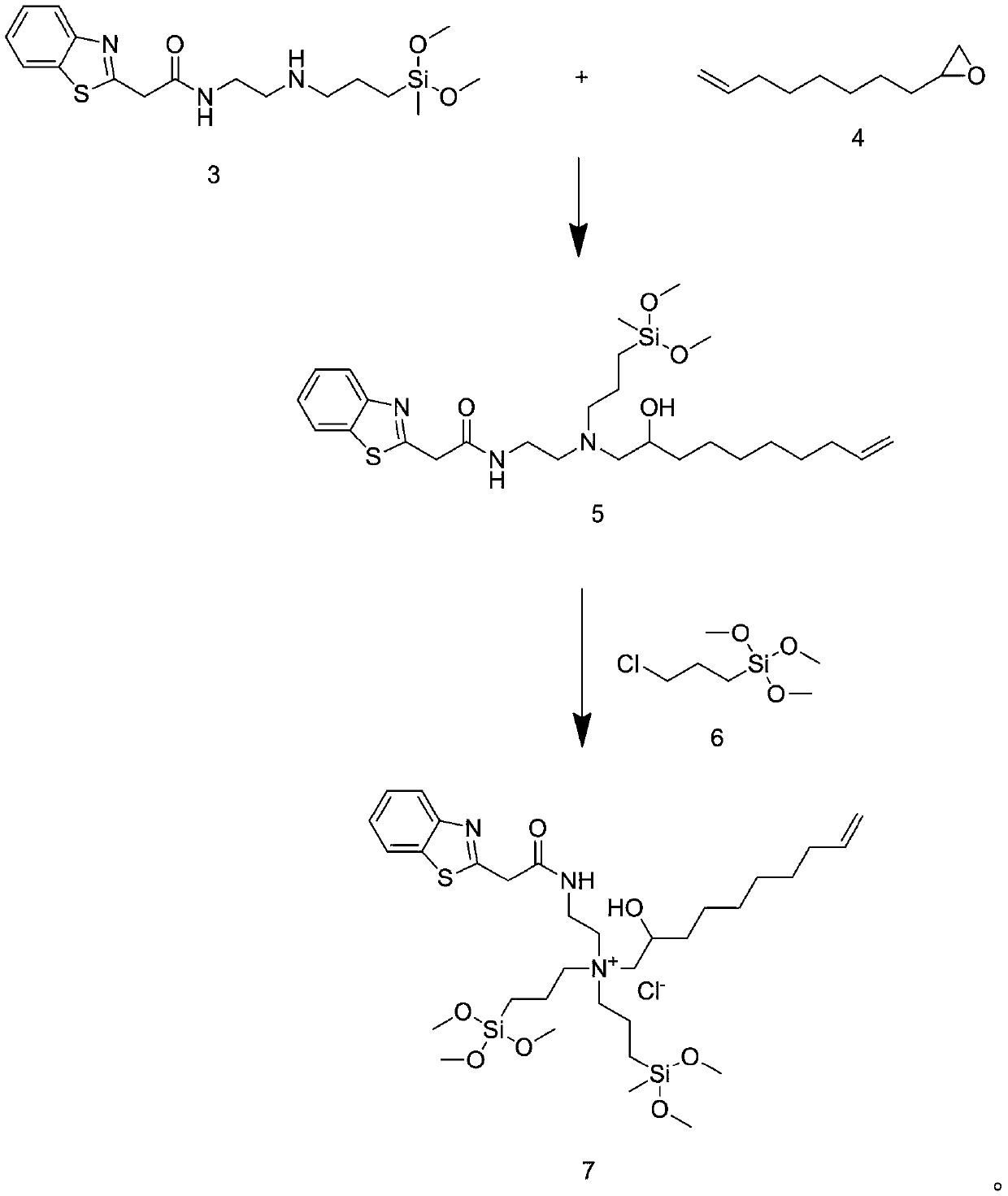

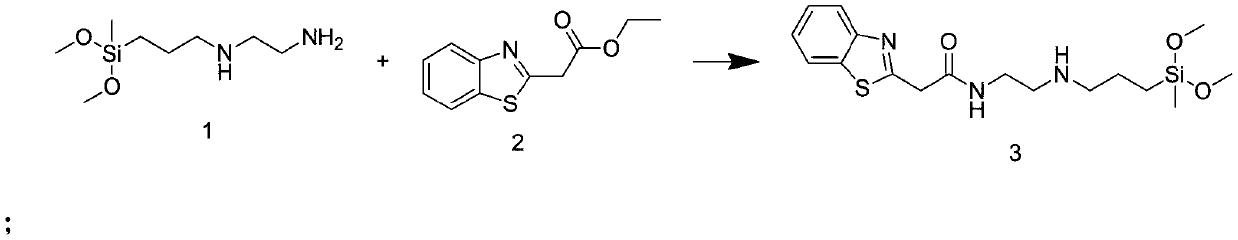

[0038] A1. Add 10mmol 2-(2-benzothiazole)ethyl acetate 2 and 800ml DMF as a solvent into the reaction kettle, start stirring, heat up to 95°C, add 0.2mmol sodium ethoxide, then dropwise add 10.6mmol aminoethylaminopropyl Dimethoxysilane 1 was fed into nitrogen gas at the same time, stirred and reacted for 3 hours, after the reaction was completed, the solvent and the reacted methanol were distilled off under reduced pressure to obtain amide compound 3 with a yield of 95.2%. The reaction formula is as follows:

[0039]

[004...

Embodiment 2

[0046] A kind of architectural powder coating with anti-mold performance, including the following raw materials in parts by weight: 55g modified acrylic resin, 8g polyvinyl acetate emulsion, 6g polyurethane, 20g titanium dioxide, 1g leveling agent polyacrylic acid, 1.5g antioxidant 1010 ;

[0047] The preparation method of this architectural powder coating is:

[0048] S1, preparation of modified acrylic resin

[0049] The modified acrylic resin is formed by free radical solution polymerization of 60g of 2-methyl methacrylate monomer, 30g of polyethylene glycol diacrylate monomer and 10g of anti-mold modifier monomer. Include the following steps:

[0050] The first step, pre-mixing

[0051] Add 2-methyl methacrylate monomer, polyethylene glycol diacrylate monomer and mildew-resistant modifier monomer into the ball mill, grind and mix for 15 minutes, then add 1.5g initiator and 8g medium ethanol, continue Carry out grinding and mixing for 10 minutes to obtain a homogeneous ...

Embodiment 3

[0057] A kind of architectural powder coating with anti-mildew performance, comprises the raw material of following weight part: 62g modified acrylic resin, 4g polyvinyl acetate emulsion, 4g polyurethane, 30g titanium dioxide, 1.5g leveling agent polyacrylic acid, 0.5g antioxidant 1010;

[0058] The preparation method of this architectural powder coating is:

[0059] S1, preparation of modified acrylic resin

[0060] The modified acrylic resin is formed by free radical solution polymerization of 75g of 2-methyl methacrylate monomer, 20g of polyethylene glycol diacrylate monomer and 5g of anti-mold modifier monomer. Include the following steps:

[0061] The first step, pre-mixing

[0062] Add 2-methyl methacrylate monomer, polyethylene glycol diacrylate monomer and anti-mildew modifier monomer into the ball mill, grind and mix for 20 minutes, then add 2g initiator and 10g medium ethanol, and continue Grind and mix for 15 minutes to obtain a uniformly mixed premix;

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com