Cefquinome sulfate suspension injection and preparation method thereof

A technology for cefquinome sulfate and suspension injection, which is applied in the field of cefquinome sulfate suspension injection and its preparation, can solve the problems of unstable chemical properties, limited clinical application, short half-life, etc., and achieve cheap raw materials and wide Application prospect, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

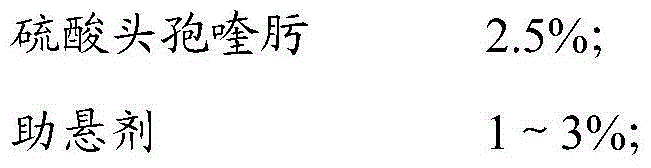

[0027] Weigh each raw material with the following mass percentage (take the total amount as 100mL as an example):

[0028]

[0029] Take ceftiofur hydrochloride and pulverize it in a pulverizer until 90% of the particles have a particle size of ≤20 μm; heat the soybean oil to 110°C, heat it for 3 hours to sterilize it, and then cool it to room temperature; add the sterilized cefotaxime sulfate, Glyceryl monostearate and vitamin E are stirred evenly to completely disperse them into a suspension; the resulting suspension is ultrafine through a ball mill to obtain the cefquinome sulfate suspension injection.

Embodiment 2

[0031] Weigh each raw material with the following mass percentage (take the total amount as 100mL as an example):

[0032]

[0033] Take ceftiofur hydrochloride and pulverize it in a pulverizer until 90% of the particles have a particle size of ≤20 μm; heat ethyl oleate to 120°C, keep it warm for 2 hours to sterilize, and then cool to room temperature; add the sterilized cefotaxime sulfate in the prescribed amount Stir the oxime, Span 80 and vitamin E evenly to make it completely dispersed into a suspension; ultrafine the obtained suspension through a ball mill to obtain the cefquinome sulfate suspension injection.

Embodiment 3

[0035] Weigh each raw material with the following mass percentage (take the total amount as 100mL as an example):

[0036]

[0037] Take ceftiofur hydrochloride and pulverize it in a pulverizer until 90% of the particles have a particle size of ≤20 μm; heat the MCT to 130° C., keep it warm for 1 hour to sterilize, and then cool to room temperature; add the sterilized cefotaxime sulfate and Disc 83 and vitamin E are stirred evenly to completely disperse them into a suspension; the obtained suspension is ultrafine through a ball mill to obtain the cefquinome sulfate suspension injection.

[0038] Observe the outward appearance of above embodiment gained cefquinome sulfate suspension injection, and carry out the mensuration of moisture and content, the result is as shown in table 1.

[0039] Table 1

[0040] Example

character

Moisture (%)

Content (%)

1

light brown suspension liquid

0.13

100.3

2

light brown suspension liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com