A synthesis method of cadmium telluride quantum dots and a synthesis method of type II cadmium telluride core-shell quantum dots

A technology for cadmium telluride quantum dots and a synthesis method is applied in the field of synthesis of quantum dots and achieves the effects of excellent environmental safety, mild reaction conditions and reasonable economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

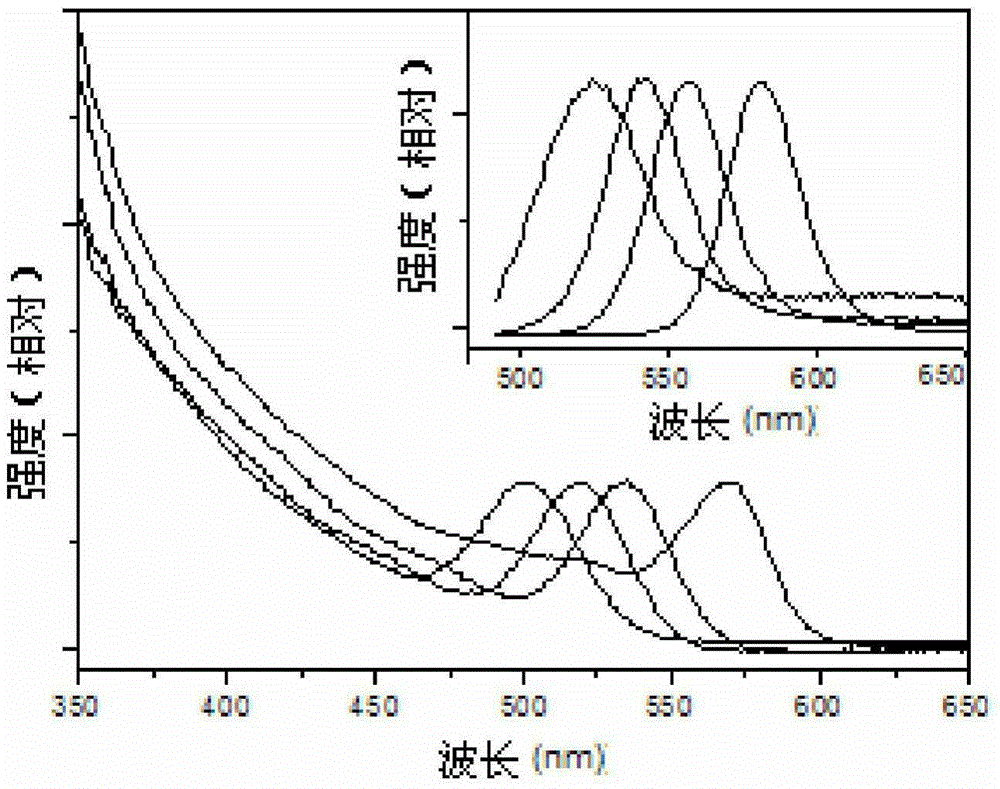

[0036] Example 1: Synthesis of CdTe quantum dots in octadecene medium

[0037] 0.2mmol cadmium stearate, 0.2mmolTe(OCH 2 CH 2 O) 2 , 0.80mmol of dodecyl mercaptan and 9.60g of octadecene were added to a 25mL three-necked flask, protected by argon, heated to 220°C at a heating rate of 20°C / min under stirring, and kept for 5 minutes; to 240°C (heating time is 40min), heat preservation reaction for 5min, stop heating after the reaction is over, pour the reaction liquid into 50mL of absolute ethanol when the reaction liquid is cooled to 50°C, precipitate cadmium telluride quantum dots, and then anhydrous Ethanol is used as a non-solvent, n-hexane is used as a solvent, the cadmium telluride quantum dots are precipitated and dissolved three times, the quantum dots are purified, and finally dried.

[0038] When the temperature of the reaction solution reaches 220°C, samples are taken at regular intervals, added to toluene, and spectroscopically measured to observe the reaction pro...

Embodiment 2

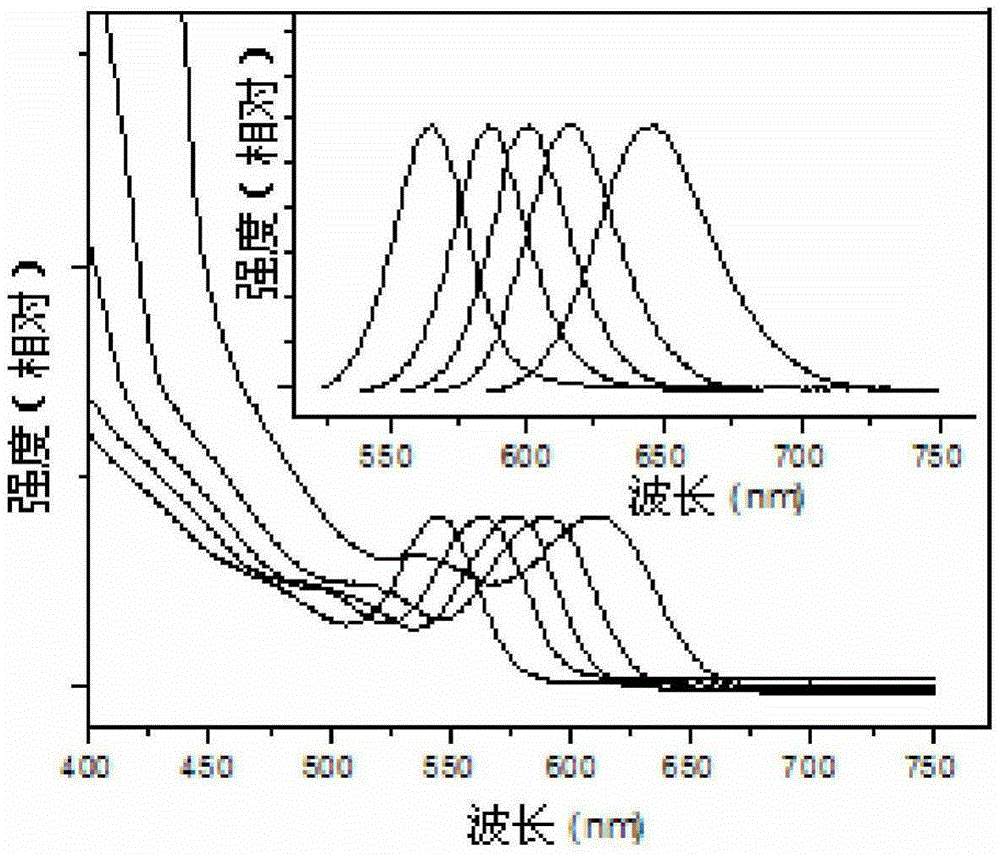

[0039] Example 2: Synthesis of CdTe / CdS quantum dots in octadecene medium

[0040] 0.2mmol cadmium stearate, 0.2mmolTe(OCH 2 CH 2 O) 2 , 0.80mmol of dodecyl mercaptan and 9.60g of octadecene were added to a 25mL three-necked flask, protected by argon, heated to 220°C at a heating rate of 20°C / min under stirring, and kept for 5 minutes; to 230°C (heating time is 10min), heat preservation reaction for 5min, and stop heating after the reaction; when the reaction solution is cooled to 100°C, add 0.2mmol cadmium stearate and 0.19mmol diallyl disulfide (prepared to 0.2mol / Diallyl disulfide octadecene solution of L) was added), the temperature was raised to 180-190°C at a heating rate of 10°C / min, the heat preservation reaction was carried out for 40min, and the heating was stopped to complete the first shelling; When the temperature is below 100°C, add 0.2mmol cadmium stearate and 0.19mmol diallyl disulfide (prepared to add 0.2mol / L diallyl disulfide octadecene solution) to the ...

Embodiment 3

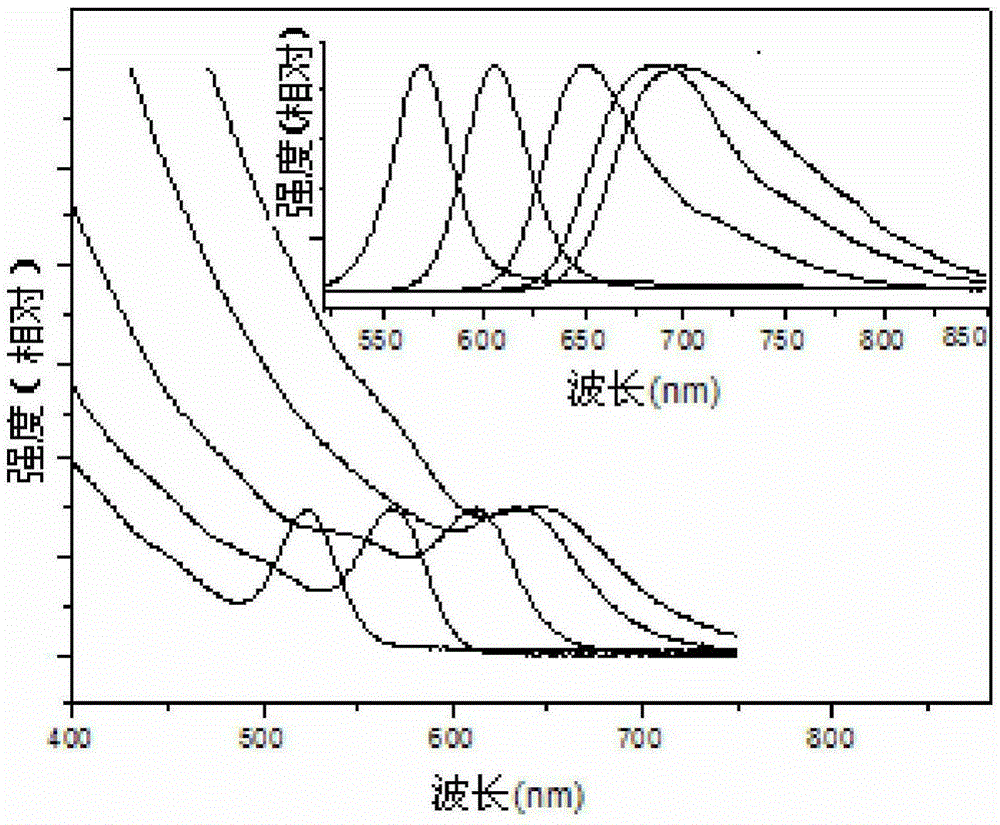

[0042] Example 3: Synthesis of CdTe / CdSe quantum dots in octadecene medium

[0043] 0.2mmol cadmium stearate, 0.2mmolTe(OCH 2 CH 2 O) 2 , 0.80mmol of dodecyl mercaptan and 9.60g of octadecene were added to a 25mL three-necked flask, protected by argon, heated to 220°C at a heating rate of 20°C / min under stirring, and kept for 5 minutes; to 240°C (heating time is 30min), heat preservation reaction for 5min, and stop heating after the reaction; when the reaction liquid is cooled to 100°C, add 0.2mmol cadmium stearate and 0.19mmol dibenzyl selenide (prepared to 0.2mol / L Dibenzyl selenide octadecene solution is added), the heating rate is 15°C / min, the temperature is raised to 200-210°C, the heat preservation is 35min, the heating is stopped, and the first shelling is completed; when the temperature of the reaction solution drops below 100°C, it is heated again Add 0.2mmol cadmium stearate and 0.19mmol dibenzyl selenide (prepared into 0.2mol / L dibenzyl selenide octadecene solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com