A kind of method for preparing isoborneol by continuous saponification of isoborneol acetate

A technology of isoborneol acetate and isoborneol, applied in the chemical industry, can solve the problems of high energy consumption, complicated saponification process, long reaction time, etc., to reduce the discharge of waste liquid, shorten the reaction time, and be conducive to sustainable production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

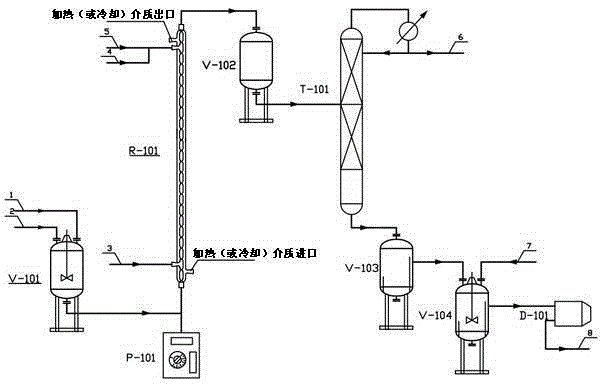

[0035] A method for preparing isoborneol by continuous saponification of isoborneol acetate, specifically comprising the following steps:

[0036] 1) Pump the sodium hydroxide aqueous solution (1) with a mass fraction of 46% and the polar solvent acetone (2) into the polar solution storage tank V-101, mix and stir evenly, and prepare a polar solution; the hydroxide The molar ratio of sodium aqueous solution to acetone is 1:3;

[0037] 2) According to the molar ratio of isobornyl acetate and sodium hydroxide as 1:1.2, pump the polar solution of isobornyl acetate (3) and step 1) into such as figure 1 In the oscillatory flow reactor R-101, the circulating water temperature is stabilized to 80°C, and the oscillatory pump P-101 is turned on at the same time, the oscillation frequency is adjusted to 4Hz, the oscillation amplitude is 0.03m, and the saponification reaction is 30min; the purity of the isobornyl acetate is 97.8%;

[0038] 3) When the height of the raw material liquid...

Embodiment 2

[0044] A method for preparing isoborneol by continuous saponification of isoborneol acetate, specifically comprising the following steps:

[0045] 1) Pump sodium hydroxide aqueous solution (1) with a mass fraction of 40% and polar solvent methanol (2) into the polar solution storage tank V-101, mix and stir evenly, and prepare a polar solution; the hydroxide The molar ratio of sodium aqueous solution to methanol is 1:1.4;

[0046] 2) According to the molar ratio of isobornyl acetate and sodium hydroxide as 1:1.15, pump the polar solution of isobornyl acetate (3) and step 1) into such as figure 1 In the oscillatory flow reactor R-101, the circulating water temperature is stabilized to 70°C, and the oscillatory pump P-101 is turned on at the same time, the oscillation frequency is adjusted to 3Hz, the oscillation amplitude is 0.05m, and the saponification reaction is 25min; the purity of the isobornyl acetate is 97.3%;

[0047] 3) When the height of the raw material liquid in...

Embodiment 3

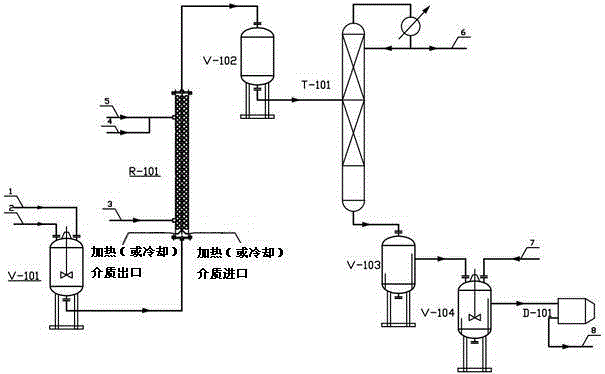

[0053] A method for preparing isoborneol by continuous saponification of isoborneol acetate, specifically comprising the following steps:

[0054] 1) Pump sodium hydroxide aqueous solution (1) with a mass fraction of 30% and polar solvent isopropanol (2) into the polar solution storage tank V-101, mix and stir evenly, and prepare a polar solution; The molar ratio of sodium hydroxide aqueous solution to isopropanol is 1:6;

[0055] 2) According to the molar ratio of isobornyl acetate and sodium hydroxide as 1:1.1, pump the polar solution of isobornyl acetate (3) and step 1) into such figure 2 Static mixer R-101, the circulating water temperature is stabilized to 60 ° C, saponification reaction 10min; the purity of the isobornyl acetate is 97.1%;

[0056] 3) When the height of the raw material liquid in the reactor reaches the height of the non-polar solvent inlet, according to the molar ratio of isobornyl acetate, non-polar solvent and water as 1:2:6, the non-polar solvent di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com