Wood-plastic composite prepared by use of short fiber and preparation method thereof

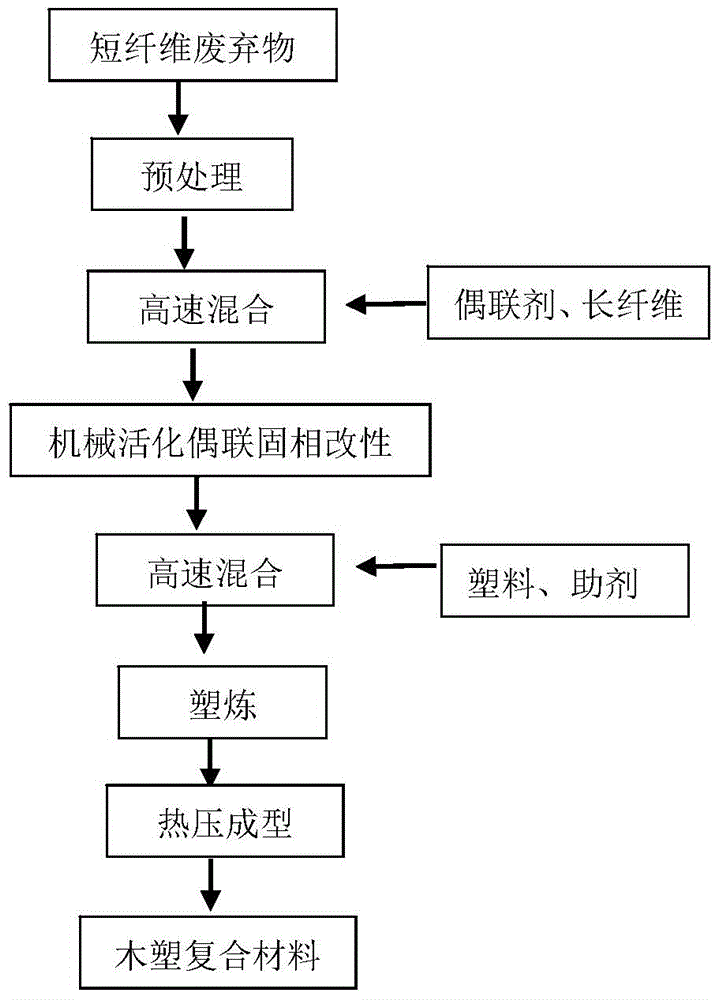

A wood-plastic composite material and short fiber technology, which is applied in the removal of solid waste and grain processing, can solve the problems of high cost and low mechanical properties, and achieve the effects of low cost, improved mechanical properties, and reduced edge wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Select 4kg of cassava wine tank short fiber, dry it at 100°C to make its water content ≤ 5%, crush it to 60 mesh, and obtain cassava wine tank powder; add the above cassava wine tank powder into the mixer, and add 0.1kg The silane coupling agent and 1 kg of sisal fiber are uniformly mixed in a high-speed mixer to obtain a mixed fiber.

[0043] Add the above-mentioned mixed fiber and grinding medium pile volume into the mechanically activated stirring ball mill according to the ratio of 100g:200ml, stir and mix at the speed of 600rpm and the temperature of the constant temperature water bath at 60°C, after the activation time of 30min is reached, stop heating and stirring, and quickly After cooling, the raw materials and balls are taken out and separated to obtain modified fibers.

[0044] The modified fiber obtained above, polyethylene plastics, calcium stearate lubricant, di-n-tin laurate heat stabilizer and β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid normal T...

Embodiment 2

[0047] Select 4.5kg of short sisal slag fibers, dry them at a high temperature of 120°C to make their water content ≤ 5%, grind them to 40 meshes, and obtain sisal slag powder; put the above sisal slag powder into a mixer, and add 0.2 Kg aluminate coupling agent and 1.5Kg sisal fiber are mixed uniformly in a high-speed mixer to obtain a mixed fiber.

[0048] Add the above-mentioned mixed fiber and grinding medium bulk volume into a mechanically activated agitating ball mill according to the ratio of 100g:300ml, and stir the reaction at a speed of 400rpm and a constant temperature water bath temperature of 65°C. After the activation time of 40min, stop heating and stirring, and quickly After cooling, the raw materials and balls are taken out and separated to obtain modified fibers.

[0049] The above-mentioned obtained modified fiber, polyvinyl chloride plastic, zinc stearate lubricant, calcium-zinc composite heat stabilizer and pentaerythritol tetrakis (bis-T-butyl hydroxyhydr...

Embodiment 3

[0052] Select 2.5kg of the mixture of sisal residue and cassava wine tank, dry it at a high temperature of 100°C to make its water content ≤ 5%, grind it to 80 mesh, and obtain short fiber powder; put the above short fiber powder into the mixer, and add 0.15Kg of aluminate and titanate mixture, 2Kg of sisal fiber and bagasse fiber mixture were uniformly mixed in a high-speed mixer to obtain mixed fibers.

[0053] Add the above-mentioned mixed fiber and grinding medium bulk volume into the mechanically activated agitating ball mill according to the ratio of 100g:400ml, stir and mix at a speed of 500rpm and a constant temperature water bath temperature of 70°C, after the activation time of 20min is reached, stop heating and stirring, and quickly After cooling, the raw materials and balls are taken out and separated to obtain modified fibers.

[0054] The modified fiber obtained above, polypropylene, oleic acid amide and calcium stearate mixture, thiol octyl ester and rare earth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com