Composite wear-resistant antifriction coating on titanium alloy surface and preparation method thereof

A surface composite and anti-friction coating technology, which is applied in the field of wear-resisting and anti-friction of titanium alloys, can solve problems such as no patent reports, improve bonding strength and bearing capacity, enhance storage and replenishment capacity, and improve surface friction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

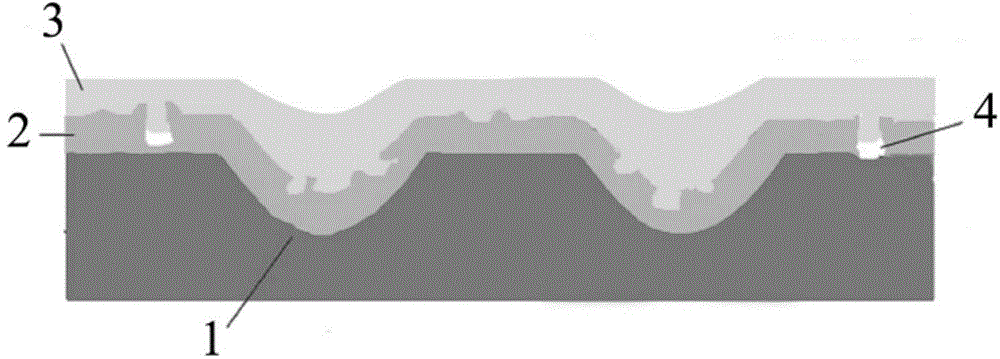

[0032] Surface Texturing / Ceramicization of a Titanium Alloy-MoS 2 The preparation method of composite coating, concrete preparation steps are as follows:

[0033] (1) Carry out polishing and degreasing pretreatment to titanium alloy substrate;

[0034] (2) Nd:YAG pulsed laser is used to texture the pretreated sample, the number of pulses at the same point is 5 times, the micropore diameter D=300 μm, the spacing L=800 μm, the depth h=55 μm, and the area occupancy rate S= 11%;

[0035] (3) Using HF-HNO 3 The solution activates the textured sample and removes surface oxides;

[0036] (4) Using the activated sample as the anode, perform plasma electrolytic oxidation treatment in the aluminate-phosphate mixed electrolyte, the electrolyte contains 12g / L of sodium aluminate, 1g / L of sodium phosphate, and 0.3g of sodium hydroxide / L, pH=12, where the pulse voltage is 460V, the pulse frequency is 100Hz, the duty cycle is 20%, and the processing time is 60min;

[0037] (5) Deposit ...

Embodiment 2

[0039]A kind of preparation method of titanium alloy surface texturing / ceramization-PTFE composite coating, concrete method is as follows:

[0040] (1) Carry out polishing and degreasing pretreatment to titanium alloy substrate;

[0041] (2) Nd: YAG pulsed laser is used to texture the pretreated sample, the number of pulses at the same point is 1, the micropore diameter D = 50 μm, the spacing L = 300 μm, the depth h = 15 μm, and the area occupancy rate S = 2%;

[0042] (3) Using HF-HNO 3 The solution activates the textured sample and removes surface oxides;

[0043] (4) Using the activated sample as the anode, carry out plasma electrolytic oxidation treatment in the phosphate electrolyte, the electrolyte contains sodium phosphate 15g / L, sodium hydroxide 1g / L, pH=14, wherein the pulse voltage is 400V, pulse Frequency 1kHz, duty cycle 10%, processing time 10min;

[0044] (5) On the textured / ceramic surface, a coating process is used to deposit a lubricating coating of nano-P...

Embodiment 3

[0046] A kind of preparation method of titanium alloy surface texturing / ceramization-graphite composite coating, concrete method is as follows:

[0047] (1) Carry out polishing and degreasing pretreatment to titanium alloy substrate;

[0048] (2) Nd: YAG pulsed laser is used to texture the pretreated sample, the number of pulses at the same point is 3 times, the micropore diameter D = 260 μm, the spacing L = 300 μm × 500 μm, the depth h = 35 μm, and the area occupancy S = 35%;

[0049] (3) Using HF-HNO 3 The solution activates the textured sample and removes surface oxides;

[0050] (4) Using the textured sample as the anode, conduct plasma electrolytic oxidation treatment in the aluminate electrolyte, the electrolyte contains 5g / L sodium aluminate, 0.6g / L sodium hydroxide, pH=13, where the pulse voltage 430V, pulse frequency 500Hz, duty cycle 15%, processing time 30min;

[0051] (5) On the textured / ceramic surface, a nano-graphite lubricating coating was deposited by a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com