Viscose fiber X-ray tracking line containing high-dose barium sulfate

A viscose fiber and barium sulfate technology, which is applied in the field of X-ray tracking line, can solve the problems of high difficulty of X-ray tracking line, long process flow and high processing difficulty, so as to expand application fields, reduce costs, and improve social and economic benefits. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

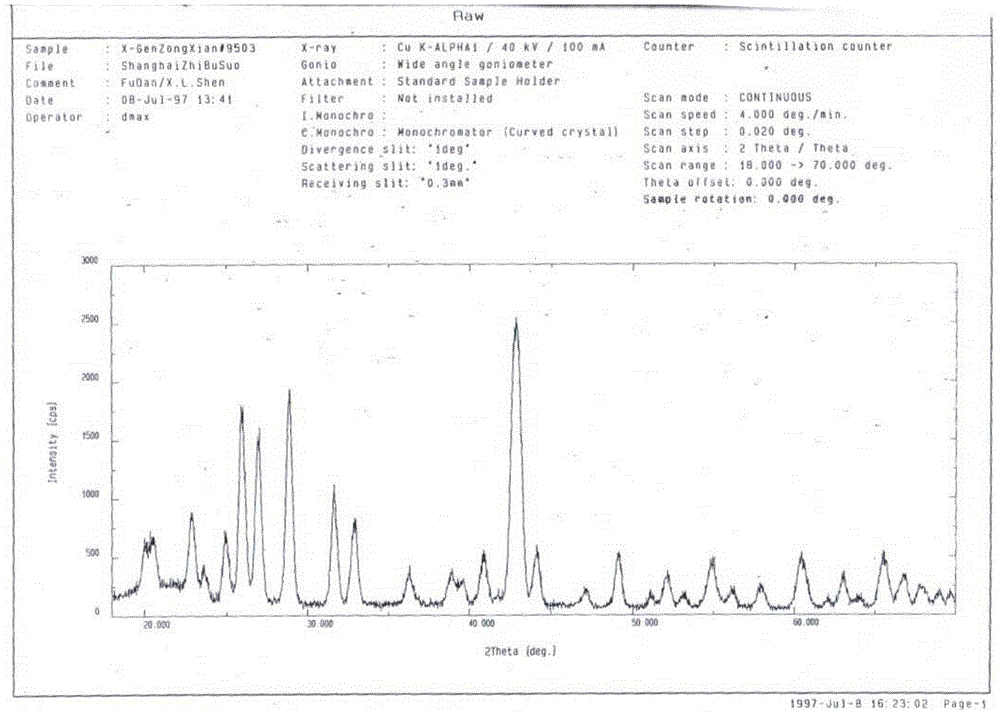

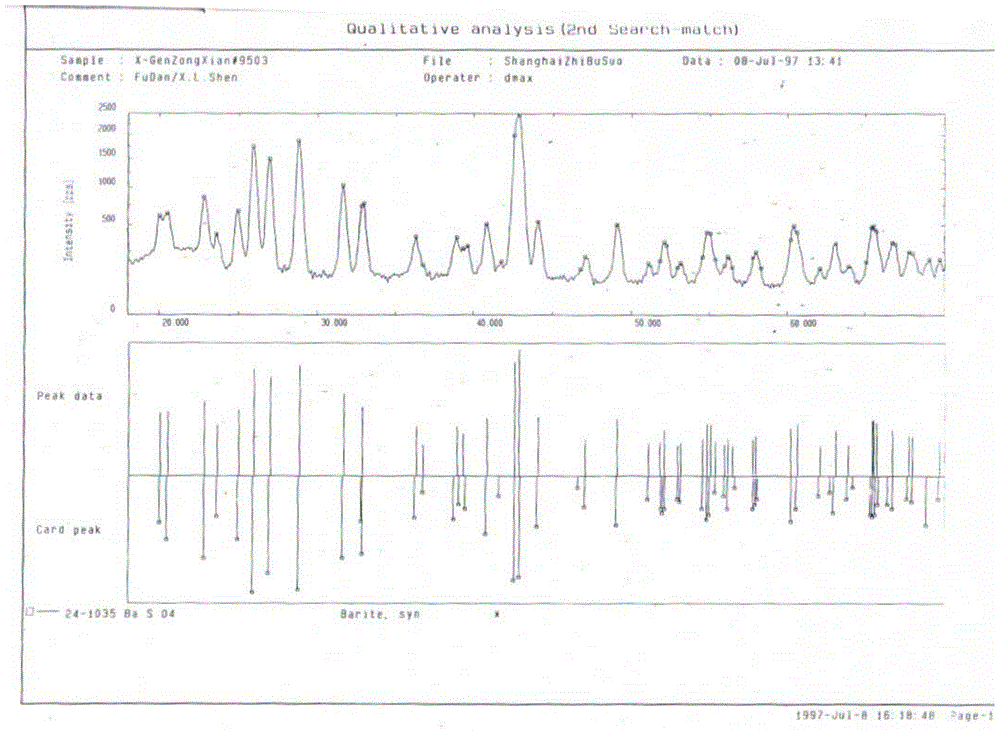

[0046] The X-ray tracing line includes barium sulfate grinding liquid and viscose slurry.

[0047] 1. Preparation of barium acid grinding solution

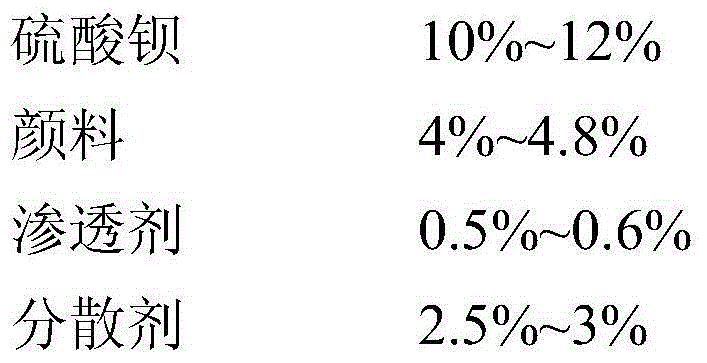

[0048] Grind the barium sulfate particles so that more than 95% of the particles are below 3um, the purity of the barium sulfate is 98%, and the weight percentage is 10%, and then the weight percentage is respectively pigment: ketone phthalocyanine 4%, dispersant: fatty alcohol Polyoxyethylene ether silane 2.5%, penetrating agent: fatty alcohol polyoxyethylene ether 0.5%, leveling agent: fatty alcohol ethylene oxide condensate 0.4%, defoaming agent: alkyl silicone oil 0.5%, water 82.1%, made into a certain concentration of emulsion.

[0049] 2. Preparation of viscose slurry

[0050] Viscose fiber belongs to regenerated cellulose fiber, which is made of natural cellulose such as wood or cotton linters. The biggest feature of viscose fiber is that it is similar to some properties of natural fiber cotton. Viscose fiber has good mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com