Tiamulin fumarate granule and preparation method thereof

A technology of tiamulin fumarate and granules, which is applied in the directions of antibacterial drugs, pharmaceutical formulations, and medical preparations with inactive ingredients, etc. The effect of increasing feeding rate, reducing moisture absorption, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

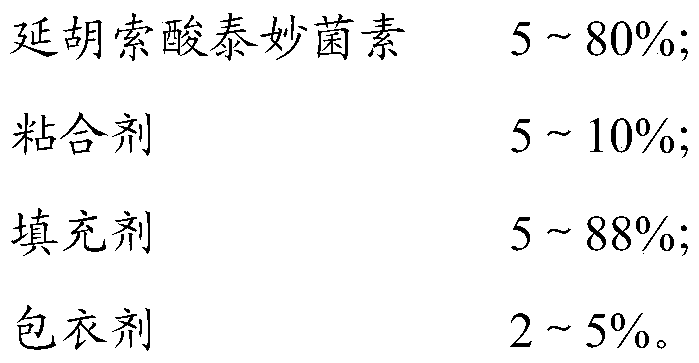

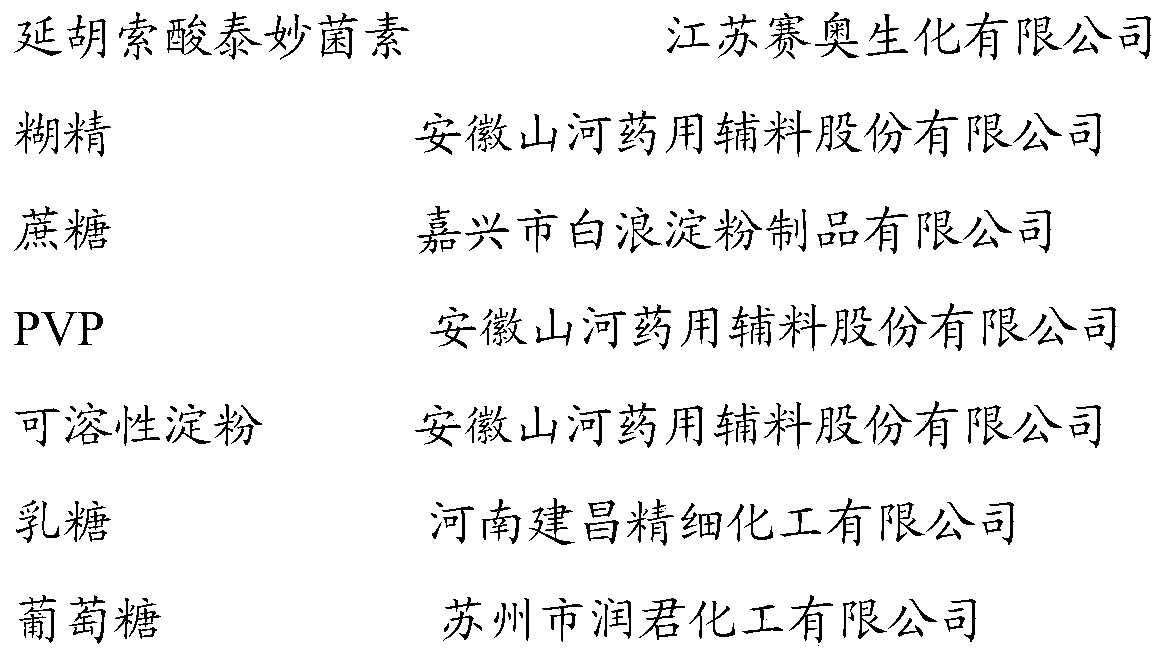

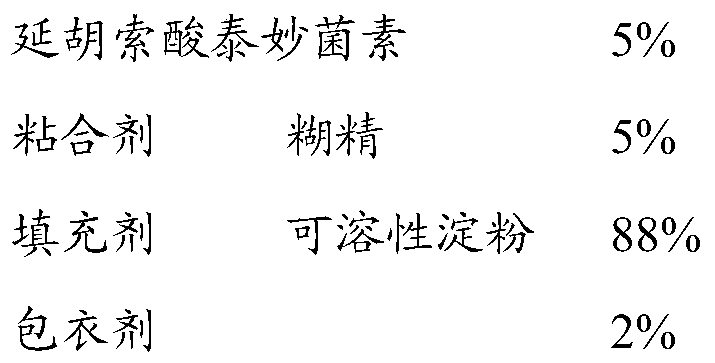

[0034] Weigh each raw material with the following mass percentage (take the total amount as 100g as an example):

[0035]

[0036] Grind and sieve tiamulin fumarate, binders and fillers, mix them evenly, then pour into a boiling granulator and spray pure water into granules, then dry the plain granules; spray the coating solution, and After drying, take out and pass through a 30-60 mesh sieve; finally obtain the finished product of tiamulin fumarate granules.

[0037] Conditions for boiling granulation: the pure water used is 60%, the fan frequency is 15Hz, the air inlet temperature is 50°C, the atomization pressure is 0.4MPa, and the peristaltic pump speed is 5mL / min. The coating liquid prescription is: 1gHPMC, 20mL ethanol, 1mL Tween-80, 10mL pure water.

[0038] The morphological investigation, determination of drug loading, and encapsulation efficiency of the obtained odorless granules were carried out, wherein the morphological investigation was to observe the shape o...

Embodiment 2

[0040] Weigh each raw material with the following mass percentage (take the total amount as 100g as an example):

[0041]

[0042] Grind and sieve tiamulin fumarate, binders and fillers, mix them evenly, then pour into a boiling granulator and spray pure water into granules, then dry the plain granules; spray the coating solution, and After drying, take out and pass through a 30-60 mesh sieve; finally obtain the finished product of tiamulin fumarate granules.

[0043] Conditions for boiling granulation: the pure water used is 20%, the fan frequency is 25Hz, the air inlet temperature is 40°C, the atomization pressure is 1.2MPa, and the peristaltic pump speed is 255mL / min. The coating liquid prescription is: 2gHPMC, 20mL ethanol, 0.2gPEG6000, 10mL pure water.

[0044] According to the method described in Example 1, the morphology of the obtained odorless granules was investigated, and the drug loading and encapsulation efficiency were measured. The specific results are shown...

Embodiment 3

[0046] Weigh each raw material with the following mass percentage (take the total amount as 100g as an example):

[0047]

[0048]

[0049] Grind and sieve tiamulin fumarate, binder and filler respectively and mix them evenly, pour into the boiling granulator and spray into the aqueous solution of PVP (5g) to granulate, then dry the plain granules; spray coating After drying, take it out and pass through a 30-60 mesh sieve; finally obtain the finished product of tiamulin fumarate granules.

[0050] Conditions for boiling granulation: the pure water used is 40%, the fan frequency is 30Hz, the air inlet temperature is 30°C, the atomization pressure is 0.8MPa, and the peristaltic pump speed is 155mL / min. The coating liquid prescription is: 2gHPMC, 30mL ethanol, 0.2g PEG6000, 1mL Tween-80, 0.1g talcum powder, 10mL pure water.

[0051] According to the method described in Example 1, the morphological investigation, the determination of drug loading, and the determination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com