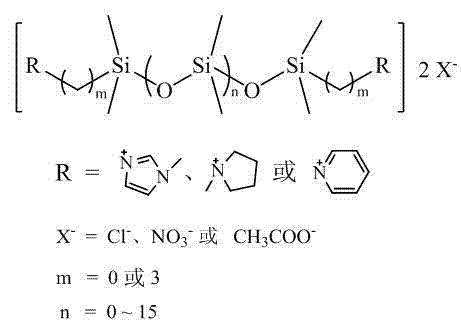

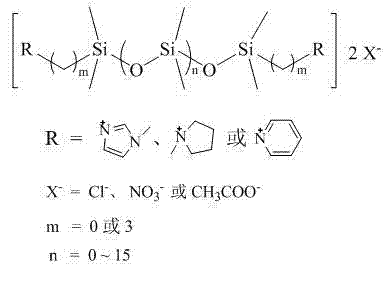

Method for preparing Bola ionic liquid type organosilicon surfactant

A technology of surfactants and ionic liquids, which is applied in the field of synthesis of silicone surfactants, can solve the problems affecting the activity of surfactants and unsatisfactory surface tension, and achieve easy operation, excellent thermal stability and biophase The effect of capacitive and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 6.0 g of octamethylcyclotetrasiloxane, 2.9 g of 1,3-di(chloropropyl)tetramethyldisiloxane, and the addition of concentrated sulfuric acid catalyst in the reactor are 2% (mass fraction), After stirring at room temperature for 2-4 hours, wash with water until neutral, and remove from low boiling. α, ω-dichloropropylpolysiloxane was obtained with a degree of polymerization of 6.6.

[0024] In a 100ml three-neck flask equipped with a condenser tube, add 5.0 g α, ω-dichloropropyl polysiloxane, 6.0 g N-methylimidazole, 10 ml isopropanol, N 2 React at 85°C for 36 hours under protection, and cool to room temperature naturally after the reaction. Pour into 30 ml of ethyl acetate to precipitate the crude product, pour off the upper layer solution, and then add 2 ml of anhydrous methanol to dissolve the crude product. Then the dissolved product was added to 30 ml of ethyl acetate to precipitate again, and the dissolution-precipitation was repeated 5 times with anhydrous methanol...

Embodiment 2

[0026] 6.0 g of octamethylcyclotetrasiloxane, 2.9 g of 1,3-di(chloropropyl)tetramethyldisiloxane, and concentrated sulfuric acid catalyst were added in an amount of 2% (mass fraction) in the reactor, After stirring at room temperature for 2-4 hours, wash with water until neutral, and remove from low boiling. α, ω-dichloropropyl polysiloxane was obtained, and the polymer was 6.6.

[0027] In a 100 ml three-necked flask equipped with a condenser tube, add 5.0 g α, ω-dichloropropyl polysiloxane, 6.2 g N-methylpyrrolidine, 10 ml isopropanol, N 2 React at 80°C for 34 hours under protection, and cool to room temperature naturally after the reaction. Pour into 30 ml of ethyl acetate to precipitate the crude product, pour off the upper layer solution, and then add 2 ml of anhydrous methanol to dissolve the crude product. Then the dissolved product was added to 30 ml of ethyl acetate to precipitate again, and the dissolution-precipitation was repeated 5 times with anhydrous methanol-...

Embodiment 3

[0029] In the reactor, 7.4 g of octamethylcyclotetrasiloxane, 2.4 g of 1,3-bis(chloromethyl)tetramethyldisiloxane, and the addition of concentrated sulfuric acid catalyst are 2% (mass fraction), Stir at room temperature for 2 to 4 hours, wash with water until neutral, and take off the low boil. α, ω-Dichloromethylpolysiloxane was obtained with a degree of polymerization of 8.9.

[0030] In a 100ml three-necked flask equipped with a condenser tube, add 5.0 g α, ω-dichloromethylpolysiloxane, 5.8 g N-methylimidazole, 20 ml isopropanol, N 2 React at 80°C for 30 hours under protection, and cool to room temperature naturally after the reaction. Pour into 40 ml of ethyl acetate to precipitate the crude product, pour off the upper layer solution, and then add 2 ml of anhydrous methanol to dissolve the crude product. Then the dissolved product was added to 30 ml of ethyl acetate to precipitate again, and the dissolution-precipitation was repeated 6 times with anhydrous methanol-ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com