High-transparency alumina ceramic preparation method

A high-transparency technology for alumina ceramics, applied in low-cost transparent ceramic preparation technology and high-temperature forging, can solve the problems of non-industrial production, reduced mechanical strength, uneven dispersion, etc., and achieves increased light transmittance and obvious light transmittance , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

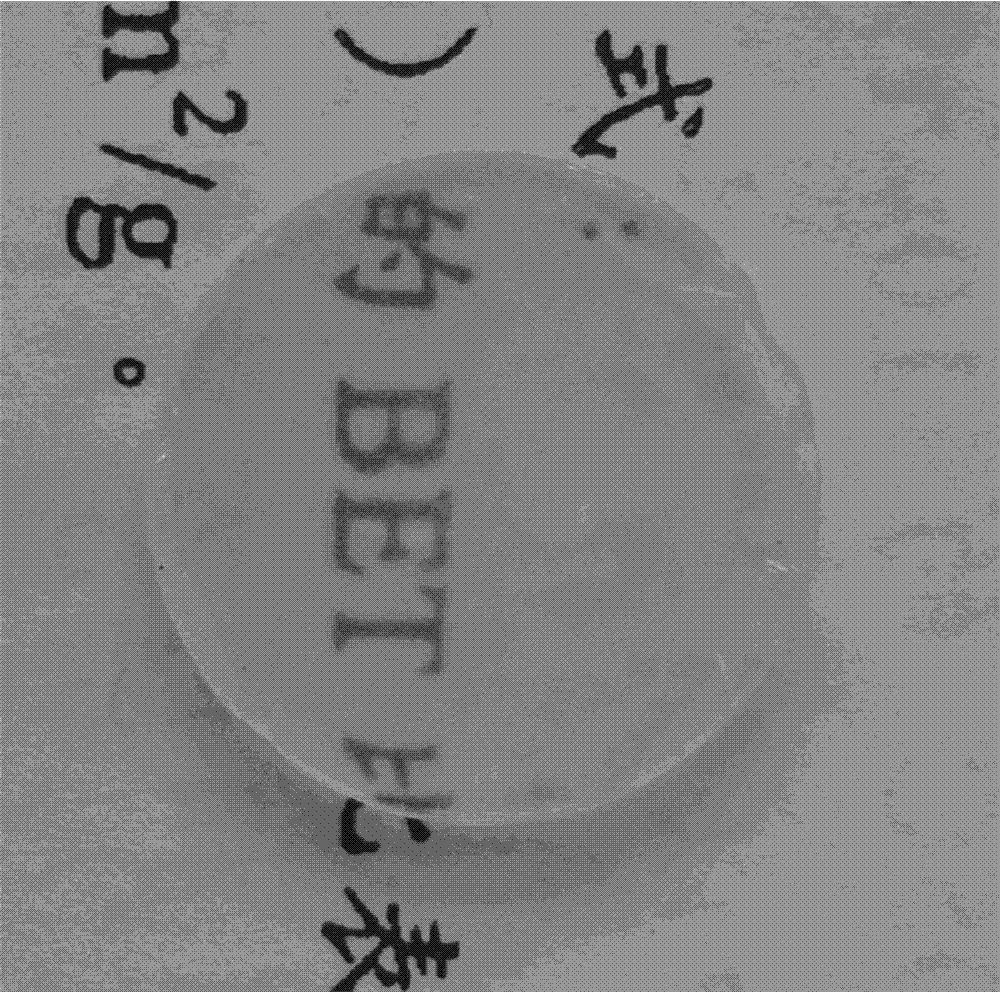

Image

Examples

Embodiment 1

[0021] The high-purity alumina powder with 0.1% by weight of magnesia was formed by 200MPa cold isostatic pressing; then the formed ceramic green body was pre-fired in an air atmosphere at 750°C for 120 minutes; the pre-fired green body was placed Sintering at 1700°C for 60 minutes in a high-temperature vacuum environment to obtain a translucent alumina ceramic body with a light transmittance of 32%; the alumina ceramic body was placed in a box furnace for post-treatment at a temperature of 1500°C, the highest Keep warm at the temperature for 2 hours; use the air hammer to forge the processed ceramic rod blank along the height direction of the slab; after forging, perform annealing treatment at 900°C for 1 hour; finally use multi-wire cutting machine, surface grinder and diamond grinding paste Cutting, grinding and polishing of ceramics.

[0022] The obtained transparent ceramic body had a relative density of 99.92% and an average grain size of 0.40 μm. The light transmit...

Embodiment 2

[0024] The high-purity alumina powder with 0.1% by weight of magnesia was formed by 200MPa cold isostatic pressing; then the formed ceramic body was pre-fired in an air atmosphere at 820°C for 150 minutes; the pre-fired body was Sintering at 1800°C for 90 minutes in a high-temperature vacuum environment to obtain a translucent ceramic body with a light transmittance of 40%; the alumina ceramic body was placed in a box furnace for post-processing at a temperature of 1600°C, and the highest temperature was Insulate for 1.5 hours; use air hammer to forge the processed ceramic rod body along the length of the slab; after forging, perform annealing treatment at 1150°C for 1.5 hours; Ceramics are cut, ground and polished.

[0025] The relative density of the obtained transparent ceramic body was 99.94%, and the average grain size was 0.60 μm. The light transmittance of transparent ceramic sheets in the visible light region (380nm~760nm) can reach 68%, while in the infrared region ...

Embodiment 3

[0028] The high-purity alumina powder with 0.2% by weight of yttrium oxide was molded by 200MPa cold isostatic pressing; then the formed ceramic green body was pre-fired in an air atmosphere at 900°C for 60 minutes; the pre-fired green body was Sintered at 1820°C for 180min in a high-temperature vacuum environment to obtain a translucent ceramic body with a light transmittance of 38%; the alumina ceramic body was placed in a box furnace for post-treatment at a temperature of 1700°C, and the highest temperature was Heat preservation for 0.5 hours; use air hammer to forge the processed ceramic rod body along the width direction of the slab; after forging, perform annealing treatment at 1250 °C for 3 hours; finally use multi-wire cutting machine, surface grinder and diamond abrasive paste to Ceramics are cut, ground and polished.

[0029] The relative density of the obtained transparent ceramic body was 99.92%, and the average grain size was 0.92 μm. The light transmittance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com