Preparation method of photo-crosslinking polyvinyl alcohol/cellulose nanocrystal (PVA/CNC) composite film

A technology of nanocrystalline cellulose and polyvinyl alcohol, which is applied in the field of polymer materials and photosensitive materials, can solve problems such as toxicity or difficult control of reactions, and achieve good physical and chemical stability, strong polarity, and high temperature resistance to permeation flux. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of PVA / CNC mixed solution: Dissolve 5g of CNC in 95mL of deionized water, prepare a suspension with a mass fraction of 1%, disperse twice with an ultrasonic cell pulverizer at a power of 25w, 60 times each time, Each step is 5 seconds, and the interval is 5 seconds to obtain a well-dispersed CNC suspension; then dissolve 3g of PVA in 34.5mL of deionized water, heat and stir at 90°C for 40min in a collector-type magnetic heating stirrer, and then Add 0.05 g of 1% CNC suspension, continue heating and stirring at 90° C. in an oil bath for 1 h to obtain a PVA / CNC mixed solution.

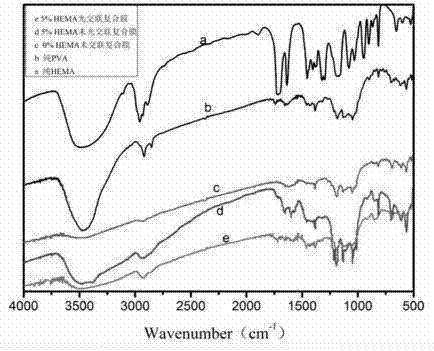

[0021] (2) Preparation of PVA / CNC composite film: After cooling the PVA / CNC mixed solution to room temperature, put it on a temperature-controlled magnetic stirrer, add 0.1222mL photocrosslinking agent HEMA (hydroxyethyl methacrylate) and 0.098g of photoinitiator 2959 (2-hydroxy-4'-(2-hydroxyethoxy)-2-methylbenzene) was stirred for 2 hours in the shade; The film was dried at 38° C...

Embodiment 2

[0024] (1) Preparation of PVA / CNC mixed solution: Dissolve 5g of CNC in 95mL of deionized water, prepare a suspension with a mass fraction of 1%, disperse twice with an ultrasonic cell pulverizer at a power of 25w, 60 times each time, Each step is 5 seconds, and the interval is 5 seconds to obtain a well-dispersed CNC suspension; then dissolve 3g of PVA in 34.5mL of deionized water, heat and stir at 90°C for 40min in a collector-type magnetic heating stirrer, and then Add 0.05 g of 1% CNC suspension, continue heating and stirring at 90° C. in an oil bath for 1 h to obtain a PVA / CNC mixed solution.

[0025] (2) Preparation of photocrosslinking PVA / CNC mixed solution: After cooling the PVA / CNC mixed solution to room temperature, put it on a temperature-controlled magnetic stirrer, add 0.1222mL photocrosslinking agent HEMA (hydroxyethyl methacrylate Esters) and 0.098g photoinitiator 2959 (2-hydroxy-4'-(2-hydroxyethoxy)-2-methylbenzene) were stirred for 2h in shading, and then the...

Embodiment 3

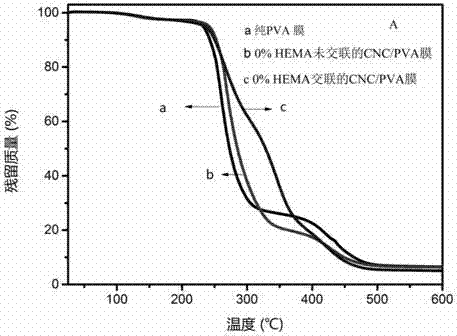

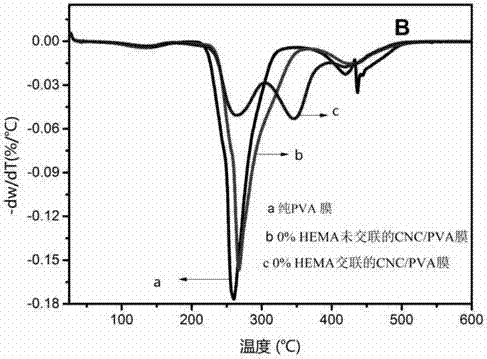

[0028] Thermogravimetric Analyzer (TGA) is used in TGA / 1100SF under nitrogen atmosphere with a heating rate of 15°C / min, and the temperature range is 25-600°C. The film (b) and the PVA-modified photocrosslinked composite film (c) were tested, and about 8-10 mg was used for each sample. Obtain the thermogravimetric graph (2) and DTG diagram (3) of the composite film etc.

[0029]It can be seen from Figure (2) that the initial decomposition temperatures of pure PVA film, PVA modified non-crosslinked composite film and PVA modified photocrosslinked composite film are 230°C, 240°C, and 235°C, respectively. As the temperature increased, the residual mass was 6.4% at 600°C. It can be seen from Figure (3) that pure PVA, PVA modified non-crosslinked composite film and PVA modified photocrosslinked composite film all slowly decompose and lose weight. PVA has an obvious weight loss peak near 260 ° C. The uncrosslinked composite film has a weight loss peak at 270 °C, and the PVA modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com