Negative ion-containing antibacterial haze-cleaning paint

An antibacterial purification and negative ion technology, applied in epoxy resin coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of general air purification effect and low air anion induction, and achieve good antibacterial effect and clean haze effect, beneficial to industrialized large-scale production, and the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

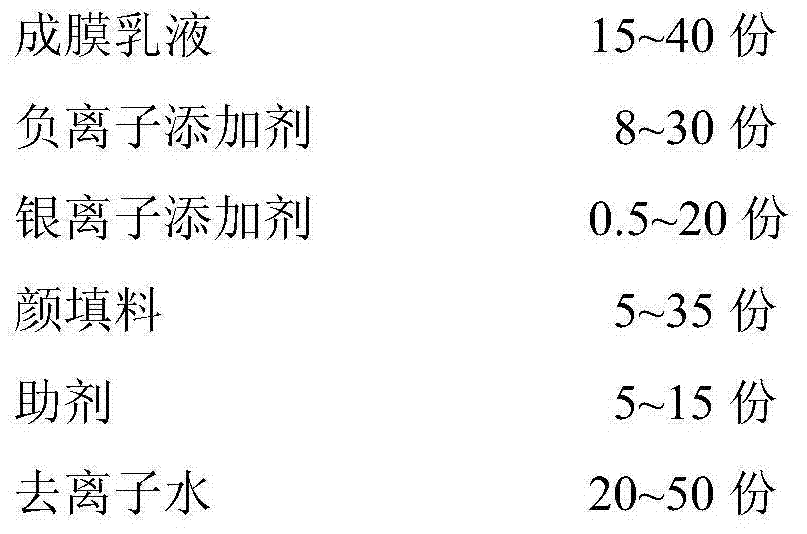

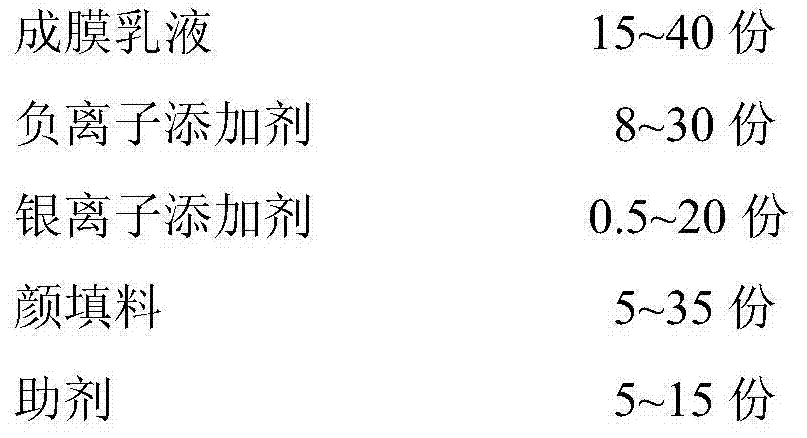

Method used

Image

Examples

Embodiment 1

[0034] Add 35 parts of deionized water, 0.7 part of propylene glycol, 3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 5 parts of talcum powder, 30 parts of negative ion additive ( The CZ-101 electro-excited nano-tourmaline produced by Hangzhou Green New Material Co., Ltd. has an anion concentration of 2000cm -3 ), 0.3 parts of polycarboxylate sodium salt dispersant (Nopco SN-5040), 1.5 parts of hydroxyethyl cellulose thickener (Dow Cellusize ER-30M) and 2-amino-2-methyl- 0.8 part of 1-propanol was ground at a speed of 1000r / min for 35min to obtain a slurry;

[0035] The slurry is transferred to a disperser, and 20 parts of pure acrylic emulsion (Rohm and Haas Easy Renda TM 2468), 5 parts of silver ion additive (Lishui Jindia YN-500, 50ppm) and 0.5 part of methyl silicone oil were added to the slurry, stirred and dispersed at a speed of 500r / min for 20min, and filtered through a 100-mesh screen to obtain The anion antibacterial and haze-cleaning paint product of t...

Embodiment 2

[0039] Add 20 parts of deionized water, 2 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 10 parts of rutile titanium dioxide, 5 parts of kaolin, and diatomaceous earth into the grinder 3 parts, 15 parts of negative ion additive (Green new material CZ-102, negative ion concentration is 10000cm -3 ), 0.5 parts of polycarboxylate sodium salt dispersant (Nopco SN-5040), 1.2 parts of hydroxyethyl cellulose thickener (Dow Cellusize ER-30M) and 2-amino-2-methyl- 0.8 part of 1-propanol was ground at a speed of 1500r / min for 20min to obtain a slurry;

[0040] Transfer the slurry to a disperser, add 30 parts of styrene-acrylic emulsion (Rohm and Haas AS-398), 0.5 parts of silver ion additive (Lishui Jindiya YN-500, 1000ppm) and 0.5 parts of methyl silicone oil to the slurry In the material, stir and disperse for 45min at a speed of 800r / min, and filter through a 90-purpose sieve to obtain the negative ion antibacterial and haze-cleaning coating product of the present inventi...

Embodiment 3

[0044]Add 50 parts of deionized water, 6.5 parts of propylene glycol, 4 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 15 parts of lithopone, and 5 parts of aluminum silicate into the grinder. parts, 5 parts of calcium carbonate, 20 parts of negative ion additives (Green new material CZ-103, negative ion concentration is 30000cm -3 ), 1.5 parts of polycarboxylate sodium salt dispersant (Nopco SN-5040), 1.2 parts of hydroxyethyl cellulose thickener (Dow Cellusize ER-30M) and 2-amino-2-methyl- 0.8 parts of 1-propanol were ground at a speed of 2000r / min for 60min to obtain a slurry;

[0045] Transfer the slurry to a disperser, add 40 parts of silicone acrylic emulsion (Oriental Yakeli BC-3206), 20 parts of silver ion additive (Lishui Jindia YN-500, 200ppm) and 1.0 part of methyl silicone oil to the slurry In the material, stir and disperse for 15min at a speed of 1500r / min, and filter through an 80-purpose sieve to obtain the negative ion antibacterial and haze-cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com