Preparation method of amorphous nanocrystalline coating based on electric-spark deposition

An amorphous nanocrystalline and electric spark deposition technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of low efficiency, increased equipment and processes, and improved enterprise efficiency, and achieves simplified process, Improved deposition efficiency and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

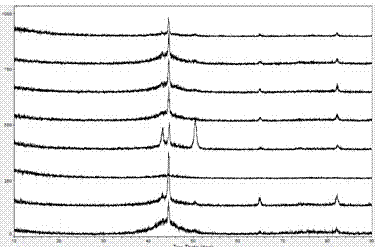

[0029] (1) FeB powder, Mo powder, Fe powder, Cr powder, Ni powder and graphite are used as raw materials to prepare Fe-6.0wt%B-48.0wt%Mo-2.5wt%Cr-3.1wt%Ni-0.5wt% The mixture of C; take 0.5% zinc stearate by weight of the above mixture and add it to the above mixture; put the mixture that has been added with the forming agent into a ball mill for ball milling, and when the ball milling is completed, the ball milled mixture Press into the required shape and size; put the pressed billet into the vacuum sintering furnace for vacuum sintering, the vacuum degree is higher than 1×10 -1 MPa, the sintering temperature is 1250°C, and the holding time is 30min.

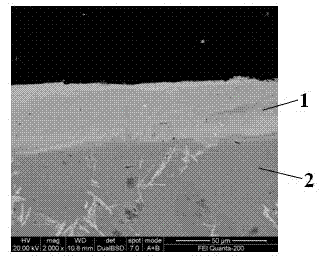

[0030] (2) The electrode material prepared in the previous step was used for EDM deposition, and protected with argon gas. The flow rate of argon gas was 8L / min. The rate is 4min / cm 2 . After every 5 min of electrode material deposition, it was cooled to room temperature before re-deposition.

Embodiment 2

[0032] (1) FeB powder, Mo powder, Fe powder, Cr powder, Ni powder and graphite are used as raw materials to prepare Fe-6.0wt%B-48.0wt%Mo-2.5wt%Cr-3.1wt%Ni-0.5wt% The mixture of C; take 0.5% zinc stearate by weight of the above mixture and add it to the above mixture; put the mixture that has been added with the forming agent into a ball mill for ball milling, and when the ball milling is completed, the ball milled mixture Press into the required shape and size; put the pressed billet into the vacuum sintering furnace for vacuum sintering, the vacuum degree is higher than 1×10 -1 MPa, the sintering temperature is 1250°C, and the holding time is 30min.

[0033] (2) The electrode material prepared in the previous step is used for EDM deposition, and protected with argon gas, the flow rate of argon gas is 0.1L / min, and the specific process parameters of deposition are: output power is 3000W, output voltage is 240V, The deposition rate is 4min / cm 2 . After every 8 min of electro...

Embodiment 3

[0035] (1) FeB powder, Mo powder, Fe powder and graphite are used as raw materials to prepare a mixture of Fe-8.0wt%B-23.62wt%Mo-0.5wt%C; Zinc fatty acid is added to the above mixture; the mixture that has been added with the forming agent is put into a ball mill for ball milling, and after the ball milling is completed, the ball-milled mixture is pressed into the required shape and size; the pressed blank is put into Vacuum sintering is carried out in a vacuum sintering furnace, and the vacuum degree is higher than 1×10 -1 MPa, the sintering temperature is 1210°C, and the holding time is 50min.

[0036] (2) Use the electrode material prepared in the previous step for EDM deposition, and use a mixed gas of argon and helium with a volume fraction of 50% for protection. The flow rate of the mixed gas is 4L / min. The specific process parameters of the deposition For: the output power is 2500W, the output voltage is 180V, the deposition rate is 4min / cm 2 . After every 15 min of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com