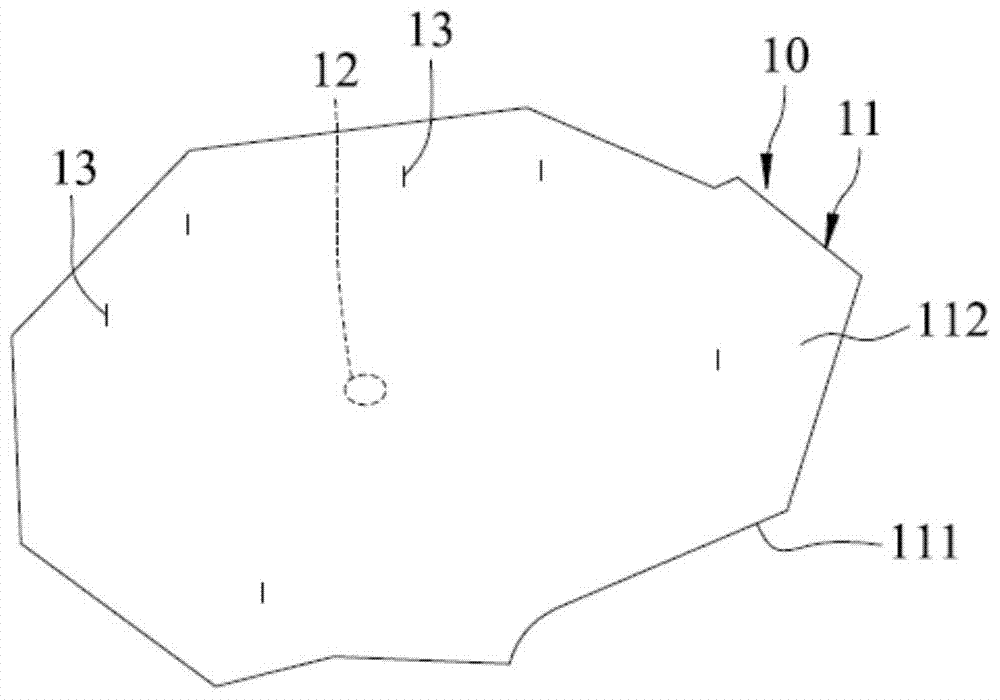

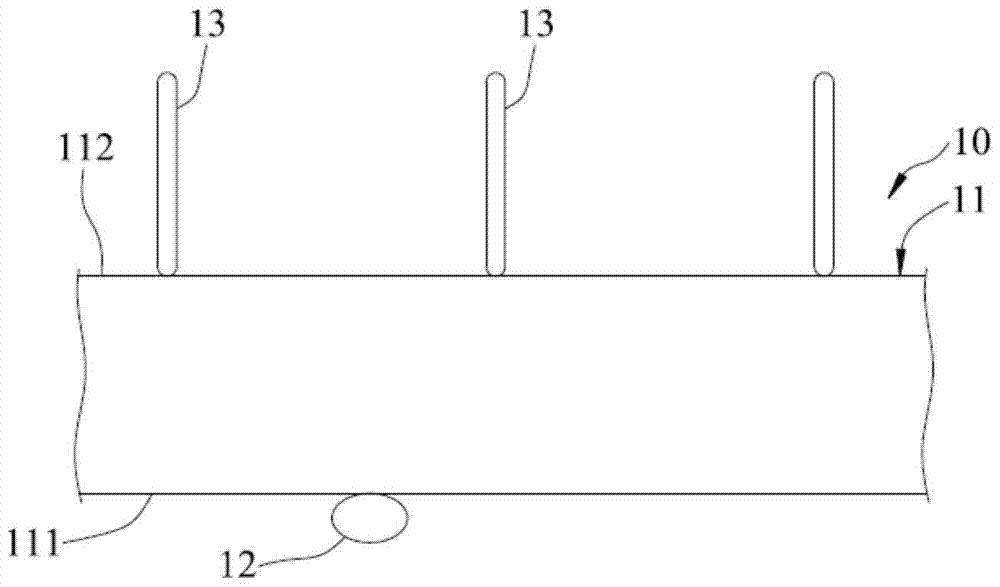

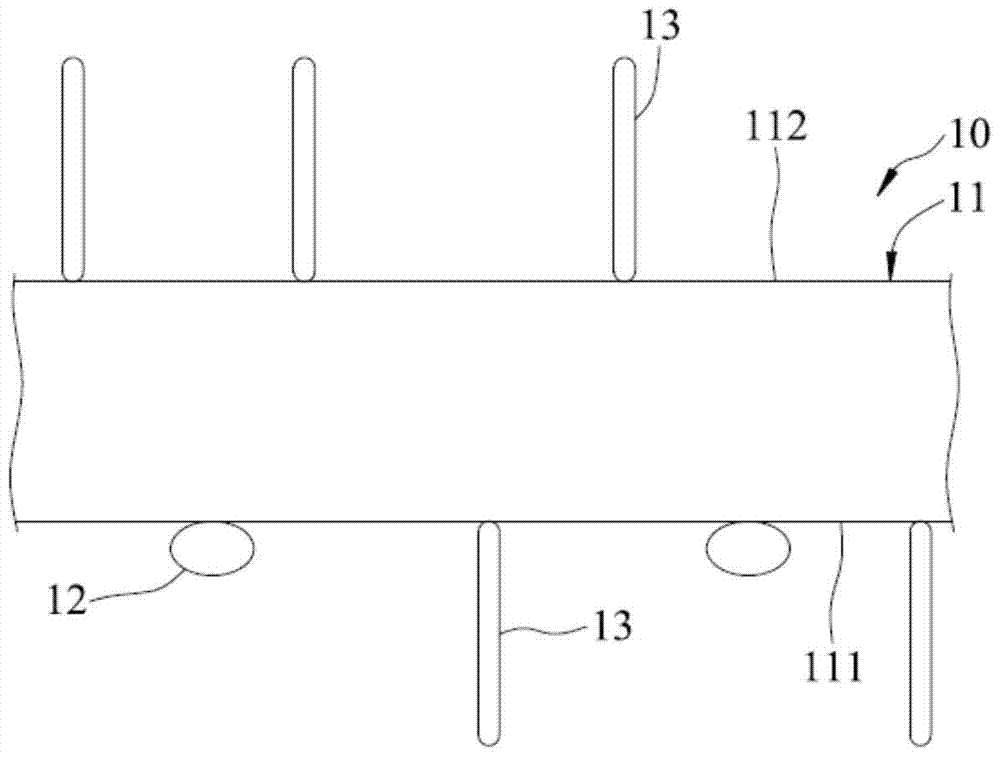

Pyroelectric material and its manufacturing method, and high-efficiency pyroelectric fiber made therefrom

A manufacturing method and pyroelectric technology, which can be applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of unsatisfactory infrared excitation and absorption efficiency, unable to generate resonance effect, etc., and achieve extensive and effective practical value. , Stable pyroelectric characteristics, the effect of increasing the cumulative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0088] Take the mineral material mixed with agate and quartzite and refine it into fragments with an average diameter of about 10 μm as the raw material of the pyroelectric substrate. The average weight of each piece of pyroelectric substrate is used to estimate the The quantity of the pyroelectric substrate, and then take the ratio of 10 gold nanoparticles and 10 carbon nanotubes corresponding to an average piece of pyroelectric substrate, and weigh specific amounts of the aforementioned three raw materials and mix them into a preset mixture, and then apply 10 to the mixed premix 8 The AC high voltage electric field of V / m is continuously applied for 20 minutes to carry out the polarization, and then the premix polarized by the high voltage electric field is dispersed and danced by an ultrasonic oscillator, so that the premix can be well mixed. In addition, the ultrasonic equipment used in this specific example uses a high-frequency pulse oscillator to generate high-frequenc...

specific example 2

[0095] Get pyroelectric material A prepared according to the preparation method of and polyethylene terephthalate (Polyethylene terephthalate, be called for short PET) master batch and mix into a composite raw material, the mixing ratio is 98.7 parts by weight Add 1.3 parts by weight of pyroelectric material A to the PET masterbatch (that is, the addition of pyroelectric material A in the composite raw material is 1.3wt%), melt and spin into fibers according to the existing spinning process, The prepared fibers were then woven into cloth, and a cloth piece of about 3 cm×5 cm was cut out as a test sample a. Observe the appearance of the produced fiber with a microscope, and send the sample a made of the fiber to the National Textile Products Quality Supervision and Inspection Center of the People's Republic of China, and carry out the test of the negative ion production concentration of the original sample and after washing 50 times. The method standard is CTTC F024-2007.

[...

specific example 3

[0100] Take the pyroelectric material A prepared by the method described in , and prepare it into test solutions a1, a2 and a3 with a concentration of 50 μg / ml, 100 μg / ml and 200 μg / ml respectively, and take silica ( That is, nano-silicon chips capable of inhibiting free radicals) were prepared as test solutions with a concentration of 50 μg / ml and 100 μg / ml, as a control test group. After the aforementioned test solution was cultured for 24 hours with the mouse mononuclear macrophage RAW264.7 induced by 0.01 μg / ml lipopolysaccharide (LPS for short), it was determined by western blot. The expression of inducible nitric oxide synthase (inducible nitric oxide synthase, referred to as iNOS) and β-actin (β-actin). In order to distinguish the effect of LPS, a blank test group 1 without LPS-induced macrophages and a blank test group 2 with LPS-induced macrophages without adding any test solution were set up. The culture environment and conditions were cultured, and the expression o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com