Electric stimulation antibiosis dressing device

An electrical stimulation, conductive clip technology, applied in artificial respiration, physical therapy and other directions, to prevent the formation of bacterial biofilms, easy to operate, and promote wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

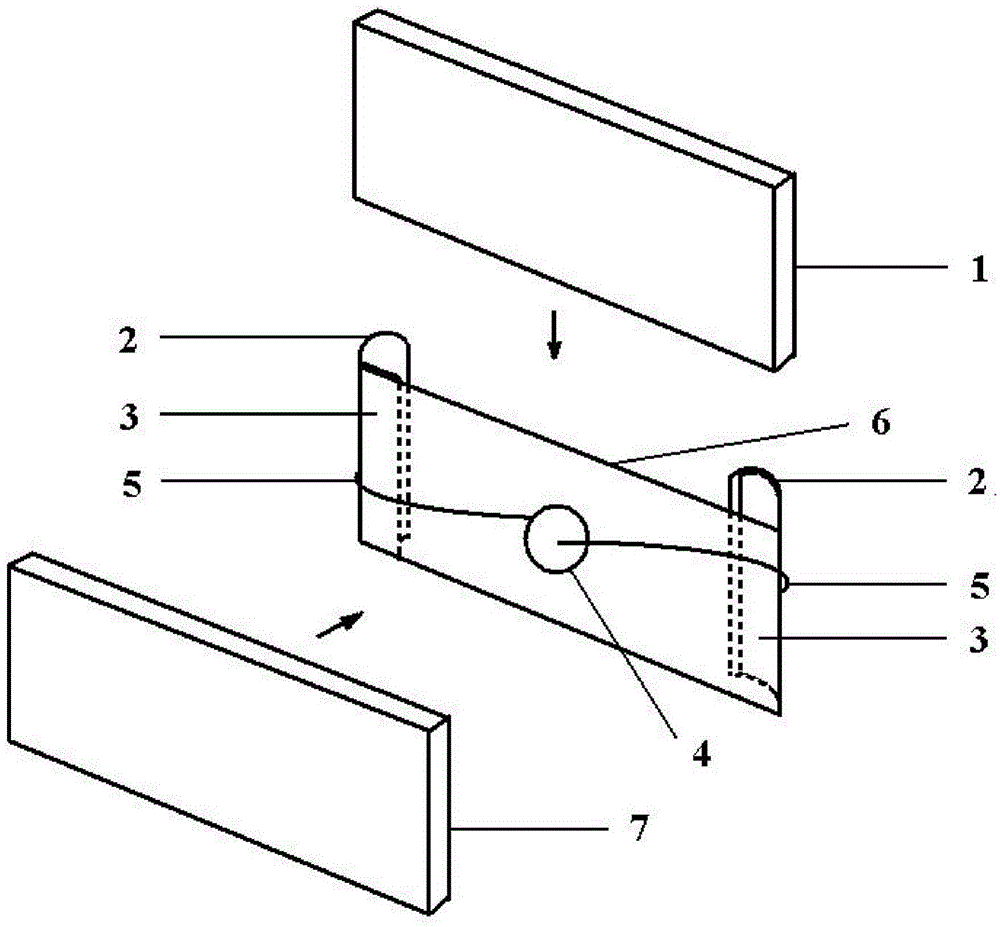

[0038] The bacterial cellulose membrane was obtained by fermentation of Acetobacter xylinum. After alkaline purification and freeze-drying, the membrane was fully immersed in a pyrrole monomer solution with a concentration of 5g / L, which contained 10μg / mL gentamicin. After 24 hours, place the film on a glass slide, apply direct current to both ends of the film, adjust the current to 0.25mA, and polymerize for 30 minutes. After the reaction was completed, the residual monomer solution on the surface was washed with deionized water. The conductivity of the conductive bacterial cellulose membrane is 0.05 S / cm. The prepared conductive bacterial cellulose dressing film 1 is fixed by insulating clips 2 and conductive clips 3, one side of the dressing film 1 is in contact with the liner 6, and the other side is exposed to the air. The conductive clips 3 located at both ends of the backing plate 6 are respectively in contact with and fixed on the front and back sides of the dressing ...

Embodiment 2

[0040]The bacterial cellulose membrane was obtained by fermentation with Agrobacterium, after alkaline purification and freeze-drying, the membrane was fully immersed in a pyrrole monomer solution with a concentration of 10g / L, which contained 10μg / mL amikacin. After 48 hours, place the film on a glass slide, apply direct current to both ends of the film, adjust the current to 0.35mA, and polymerize for 15 minutes. After the reaction was completed, the residual monomer solution on the surface was washed with deionized water. The prepared conductive bacterial cellulose dressing film 1 is fixed by insulating clips 2 and conductive clips 3, one side of the dressing film 1 is in contact with the liner 6, and the other side is exposed to the air. The conductive clips 3 located at both ends of the backing plate 6 are respectively in contact with and fixed on the front and back sides of the dressing film 1 . The conductive clip 3 is connected to the positive and negative poles of th...

Embodiment 3

[0042] The bacterial cellulose membrane was fermented by Acetobacter xylinum. After alkaline purification and freeze-drying, the membrane was fully immersed in a pyrrole monomer solution with a concentration of 5 g / L, which contained 5 μg / mL kitasamycin. After 10 hours, place the film on a glass slide, apply direct current to both ends of the film, adjust the current to 0.20 mA, and polymerize for 30 minutes. After the reaction was completed, the residual monomer solution on the surface was washed with deionized water. The prepared conductive bacterial cellulose dressing film 1 is fixed by insulating clips 2 and conductive clips 3, one side of the dressing film 1 is in contact with the liner 6, and the other side is exposed to the air. The conductive clips 3 located at both ends of the backing plate 6 are respectively in contact with and fixed on the front and back sides of the dressing film 1 . The conductive clip 3 is connected to the positive and negative poles of the butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com