Preparation method of ultrafine magnesium-based rare earth hexaaluminate powder

A hexaaluminate, ultrafine powder technology, applied in rare earth metal compounds, chemical instruments and methods, alumina/aluminum hydroxide and other directions, can solve the problems of high production cost and harsh reaction conditions, and achieve low cost, The effect of lowering the firing temperature and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

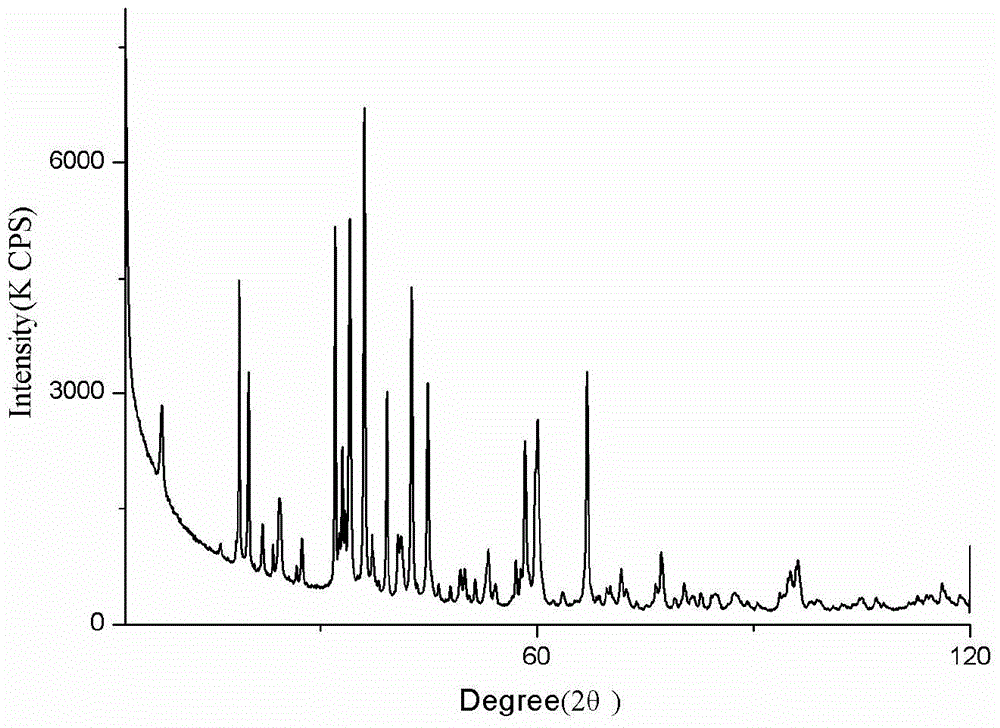

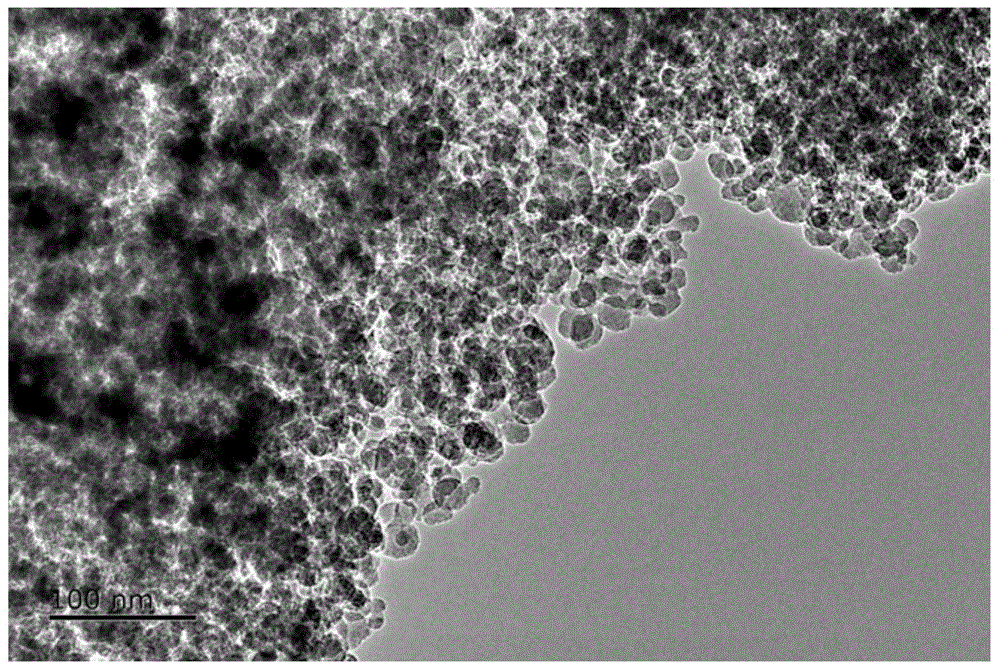

Embodiment 1

[0036] A preparation method of magnesium-based rare earth hexaaluminate ultrafine powder, comprising the following steps:

[0037] (1) Precursor colloid preparation:

[0038] a. Dissolve 375g of aluminum nitrate nonahydrate in water and stir until completely dissolved to make 1L of aluminum nitrate solution, in which Al 3+ The concentration is 1mol / L; Dissolve 203g of magnesium chloride hexahydrate in water and stir until completely dissolved to prepare 1L of magnesium chloride solution, in which Mg 2+ The concentration is 1mol / L; lanthanum oxide is dissolved in 5mol / L dilute nitric acid to prepare La 3+ A rare earth solution with a concentration of 0.05mol / L;

[0039] b. Mix the aluminum nitrate solution, magnesium chloride solution and rare earth solution prepared in step a uniformly to obtain solution A, and La in the gained solution A 3+ with Al 3+ The molar ratio of Al is 1:11, Al 3+ with La 3+ The total number of moles and Mg 2+ The molar ratio is 12:1;

[0040] c....

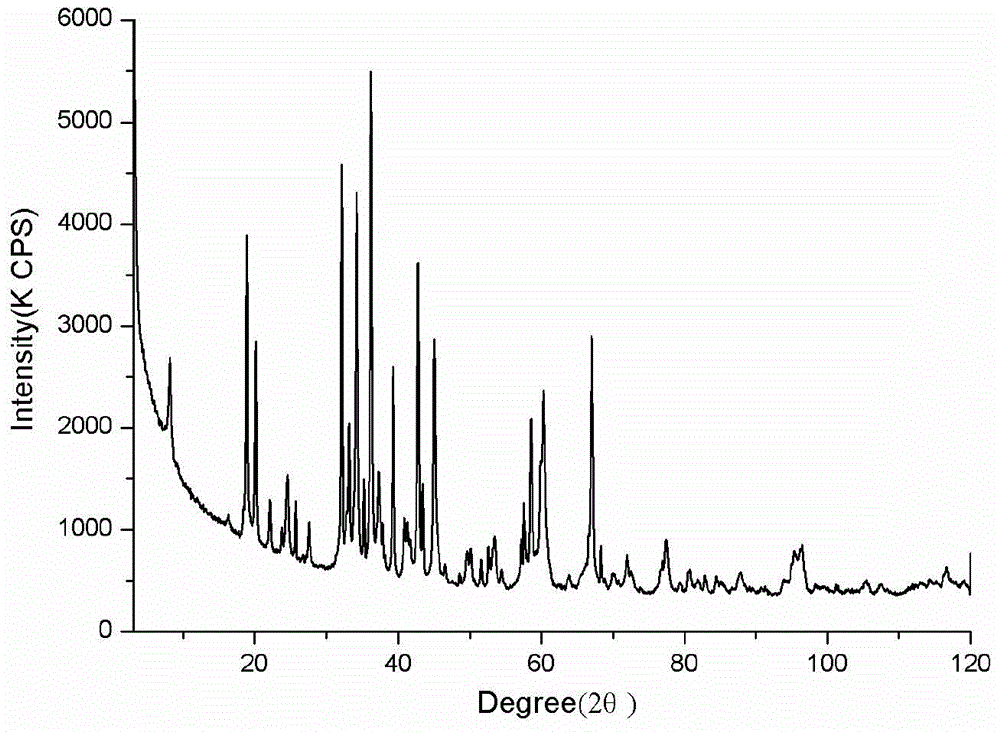

Embodiment 2

[0046] A preparation method of magnesium-based rare earth hexaaluminate ultrafine powder, comprising the following steps:

[0047] (1) Precursor colloid preparation:

[0048] a. Dissolve 187.5g of aluminum nitrate nonahydrate in water and stir until completely dissolved to prepare 1L of aluminum nitrate solution, in which Al 3+ The concentration is 0.5mol / L; Dissolve 101.5g of magnesium chloride hexahydrate in water and stir until completely dissolved to prepare 1L of magnesium chloride solution, in which Mg 2+ The concentration is 0.5mol / L; Dissolve neodymium oxide in dilute nitric acid to prepare Nd 3+ A rare earth solution with a concentration of 0.1mol / L;

[0049] b. Mix the aluminum nitrate solution, magnesium chloride solution and rare earth solution prepared in step a uniformly to obtain solution A, and the Nd in the obtained solution A 3+ with Al 3+ The molar ratio of Al is 1:50, Al 3+ with Nd 3+ The total number of moles and Mg 2+ The molar ratio is 12:1;

[0...

Embodiment 3

[0056] A preparation method of magnesium-based rare earth hexaaluminate ultrafine powder, comprising the following steps:

[0057] (1) Precursor colloid preparation:

[0058] a. Dissolve 96.4g of aluminum chloride hexahydrate in water and stir until completely dissolved to prepare 1L of aluminum chloride solution, in which Al 3+ The concentration is 0.4mol / L; Dissolve 81.2g of magnesium chloride hexahydrate in water and stir until completely dissolved to prepare 1L of magnesium chloride solution, in which Mg 2+ The concentration is 0.4mol / L; Dissolve samarium oxide in dilute nitric acid to prepare Sm 3+ A rare earth solution with a concentration of 0.2mol / L;

[0059] b. Mix the aluminum chloride solution, magnesium chloride solution and rare earth solution prepared in step a uniformly to obtain solution A. In the obtained solution A, Sm 3+ with Al 3+ The molar ratio of Al is 1:100, Al 3+ with Sm 3+ The total number of moles and Mg 2+ The molar ratio is 12:1;

[0060] c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com