A kind of synthetic method of di-tert-butyl terminated chain polysulfide

A technology of di-tert-butyl encapsulation and synthesis method, which is applied in the field of preparation of organic sulfides, and can solve problems such as low conversion rate of isobutylene and product yield, low activity of alumina, difficulty in recycling catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

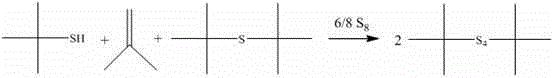

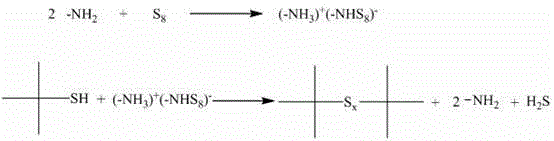

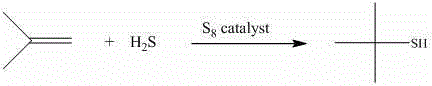

Method used

Image

Examples

Embodiment 1

[0030] Add 367.0g (11.44mol) of sulfur into a 2.5-liter reactor, add 0.734g of NH 2 - MIL-53(Al) catalyst (0.2% by mass based on sulfur), followed by a reinforced seal. Purge 3 times with 2.0MPa high-purity nitrogen, and finally release to normal pressure. Feed H into the above reaction kettle 2 S (129.8g, 3.81mol), heat up and control the temperature to 140oC, start stirring (rotating speed is about 320rpm). Start the metering pump, inject isobutene (427.6g, 7.62mol), adjust the flow rate of the metering pump so that the injection time of isobutene is 1h, and continue to react for 1h after the injection of isobutene is completed. Keep this temperature constant, release the pressure in the kettle and purging with nitrogen for 0.5h, and cool the tail gas with a primary condenser (ice water bath) and a secondary condenser (dry ice acetone bath) to recover by-products tert-butyl mercaptan and di-tert-butyl mono Sulfur ether, the cooled tail gas uses a fixed bed desulfurizer to...

Embodiment 2

[0032] Add 555.84g (17.37mol) of sulfur into a 2.5-liter reactor, add 0.556g of NH 2 -MIL-101(Al) catalysis

[0033]

[0034] When the mol ratio of hydrogen sulfide, sulfur and isobutylene was 1:3:2, the average chain length of the product was 4, and tetrasulfide was the main product in the product. When the mol ratio of hydrogen sulfide, sulfur and isobutylene was 1:2: When 2, the average chain length of the product is 3, and trisulfide is the main product in the product.

[0035] Although isobutene can be 100% converted, the by-products tert-butyl mercaptan and di-tert-butyl monosulfide are inevitably generated. Nitrogen stripping is carried out at 100 ° C, and the tail gas is passed through a primary condenser (ice-water bath) and a secondary The condenser (dry ice acetone bath) cools and recovers the by-products tert-butyl mercaptan and di-tert-butyl monosulfide, which can continue to react with sulfur to form chain di-tert-butyl polysulfide. The reaction formula is as...

Embodiment 3

[0039] Add 243.8g (7.62mol) of sulfur into a 2.5-liter reactor, add 0.975g of NH 2 - MIL-101 (Al) catalyst (0.4% by mass based on sulfur), followed by a reinforced seal. Purge 3 times with 2.0MPa high-purity nitrogen, and finally release to normal pressure. Feed H into the above reaction kettle 2 S (129.8g, 3.81mol), heat up and control the temperature at 150oC, and start stirring (rotation speed is about 320rpm). Start the metering pump, inject isobutene (427.6g, 7.62mol), adjust the flow rate of the metering pump so that the injection time of isobutene is 1h, and continue to react for 1h after the injection of isobutene is completed. Keep this temperature constant, release the pressure in the kettle and purging with nitrogen for 0.5h, and cool the tail gas with a primary condenser (ice water bath) and a secondary condenser (dry ice acetone bath) to recover by-products tert-butyl mercaptan and di-tert-butyl mono Sulfur ether, the cooled tail gas uses a fixed bed desulfuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com