A kind of graphene oxide and gold nanorod composite ink and preparation method thereof

A technology of gold nanorods and graphene, which is applied to the composite ink of graphene oxide and gold nanorods and its preparation field, can solve the problems of easy agglomeration and easy oxidation of silver, and achieve low post-processing temperature and simple preparation process , the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

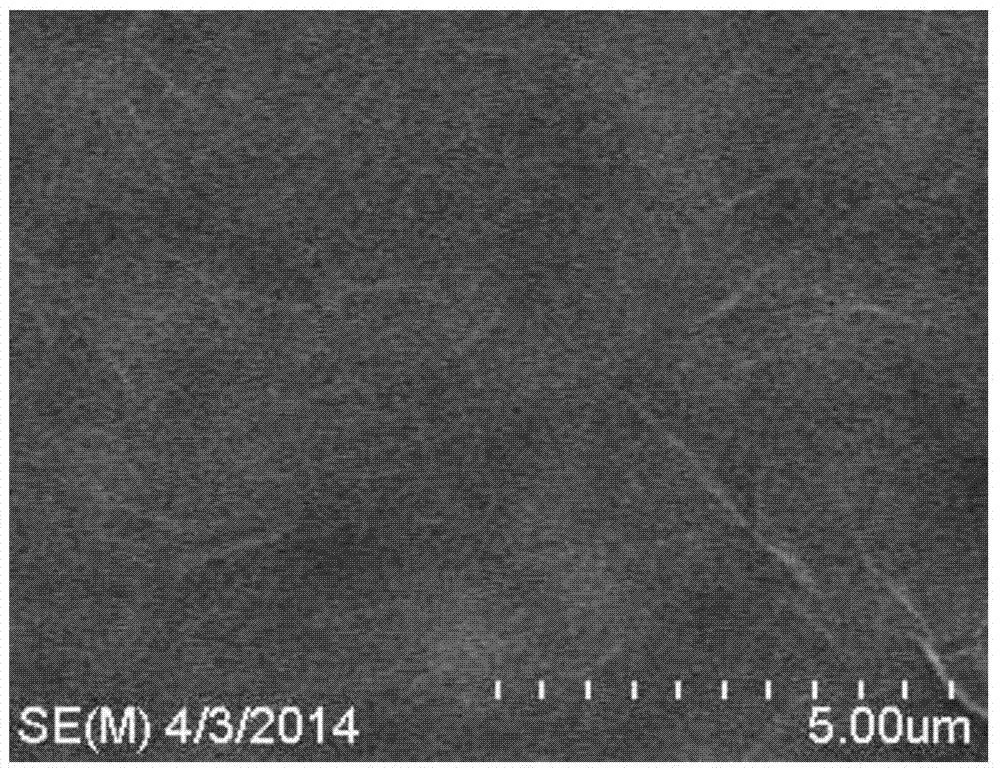

[0016] 1) The graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is processed at 200W for 5 hours with an ultrasonic crusher, and then passed through a 1.2 μM filter membrane to remove large-sized graphene oxide; the obtained solid is at room temperature Perform vacuum drying overnight to obtain graphene oxide with a size of 1000nm, which is dispersed in water to obtain a 0.05M graphene oxide dispersion;

[0017] 2) First, soak the glassware involved in the experiment in aqua regia, take it out after 3 hours, and wash it with plenty of water;

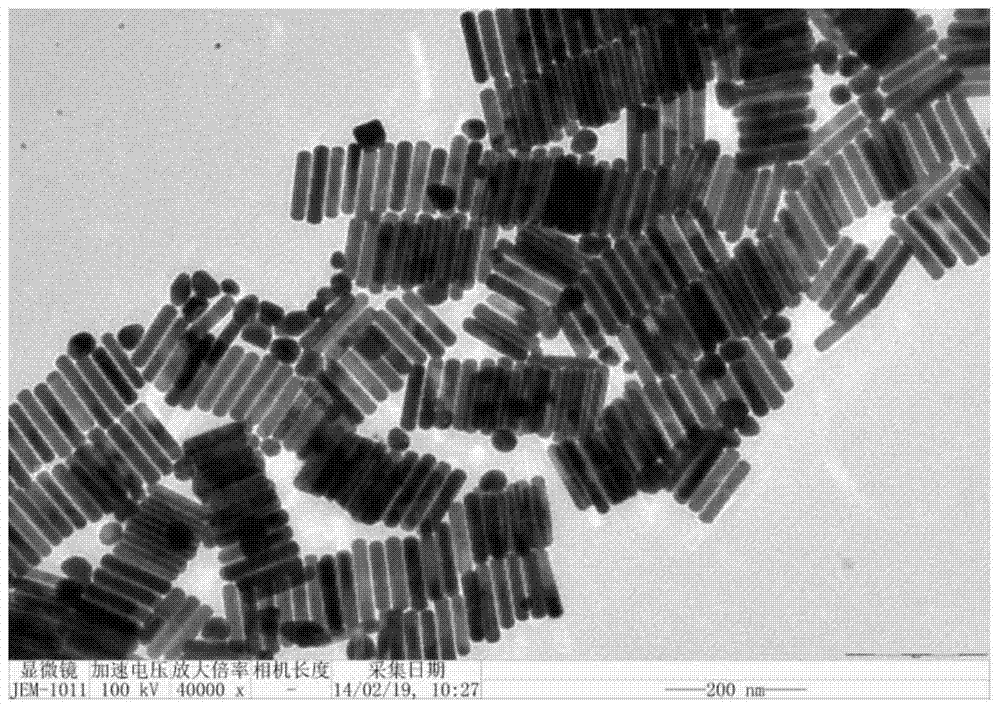

[0018] Synthetic seed solution: Add 5mL of 0.5mM chloroauric acid solution into 5mL of 0.2M cetyltrimethylammonium bromide solution, then add 0.5mL of 0.005M sodium borohydride solution, stir vigorously, the color of the solution From yellow to brown, stop stirring after 2 minutes and store at room temperature;

[0019] Dissolve 7.0g of cetyltrimethylammonium bromide and 9.0g of sodium oleate ...

Embodiment 2

[0022] 1) The graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is processed at 200W for 5 hours with an ultrasonic crusher, and then passed through a 1.2 μM filter membrane to remove large-sized graphene oxide; the obtained solid is at room temperature Perform vacuum drying overnight to obtain graphene oxide with a size of 800nm, which is dispersed in water to obtain a 0.01M graphene oxide dispersion;

[0023] 2) First, soak the glassware involved in the experiment in aqua regia, take it out after 3 hours, and wash it with plenty of water;

[0024] Synthetic seed solution: Add 5mL of 0.5mM chloroauric acid solution into 5mL of 0.2M cetyltrimethylammonium bromide solution, then add 0.5mL of 0.005M sodium borohydride solution, stir vigorously, the color of the solution From yellow to brown, stop stirring after 2 minutes and store at room temperature;

[0025] Dissolve 7.0g of cetyltrimethylammonium bromide and 9.0g of sodium oleate i...

Embodiment 3

[0029] 1) The graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is processed at 200W for 5 hours with an ultrasonic crusher, and then passed through a 1.2 μM filter membrane to remove large-sized graphene oxide; the obtained solid is at room temperature Perform overnight vacuum drying to obtain graphene oxide with a size of 1000nm, which is dispersed in water to obtain a 0.1M graphene oxide dispersion;

[0030] 2) First, soak the glassware involved in the experiment in aqua regia, take it out after 3 hours, and wash it with plenty of water;

[0031] Synthetic seed solution: Add 5mL of 0.5mM chloroauric acid solution into 5mL of 0.2M cetyltrimethylammonium bromide solution, then add 0.5mL of 0.005M sodium borohydride solution, stir vigorously, the color of the solution From yellow to brown, stop stirring after 2 minutes and store at room temperature;

[0032] Dissolve 7.0g of cetyltrimethylammonium bromide and 9.0g of sodium oleate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com