Preparation method of instant pumpkin powder

A pumpkin powder and instant technology, which is applied in food preparation, application, food science, etc., can solve the problems of low gelatinization degree of pumpkin powder starch, poor reconstitution and palatability, rough taste of the product, etc., and achieve good fluidity, powder The effect of small and loose grains and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of instant pumpkin powder, comprising the following steps:

[0027] 1) Pre-treatment: select fresh pumpkins that are half-ripe, remove spoiled and moldy pumpkins, clean the pumpkins, peel and remove seeds;

[0028] 2) crushing: crushing the above-mentioned pumpkin after deseeding into pumpkin particles with a particle size of less than 1cm×1cm with a crusher;

[0029] 3) Cooking: add 10-30% water of crushed pumpkin granules to the above-mentioned pumpkin granules, use a sandwich pot, cook at a temperature of 95-100°C for 30-35min; during this period, stir once every 5min to avoid scorching Make sure the pumpkin is boiled;

[0030] 4) beating: the product obtained in step 3) is beaten with a beater, and is divided into the first slag discharge and the second slag discharge according to the mesh diameter, (wherein the first sieve mesh aperture is Φ1.2mm, and the second sieve mesh aperture is Φ0.6mm), the first slag is first passed through the colloi...

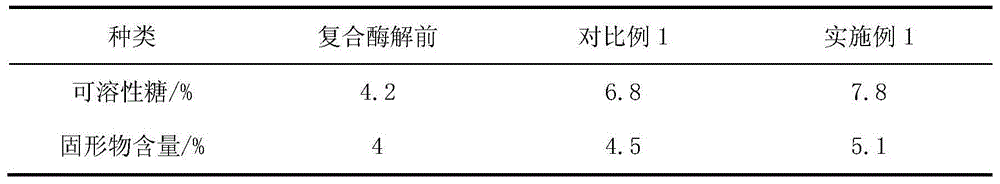

Embodiment 1

[0040] A preparation method of instant pumpkin powder, comprising the following steps:

[0041] 1) Pre-treatment: select fresh pumpkins that are half-ripe, remove spoiled and moldy pumpkins, clean the pumpkins, peel and remove seeds;

[0042] 2) crushing: the above-mentioned pumpkin after seed removal is crushed into pumpkin particles with a particle size of less than 1cm with a crusher;

[0043] 3) Cooking: Add 20% water of the crushed pumpkin granules to the above pumpkin granules, use a sandwich pot, and cook at a temperature of 95-100°C for 30 minutes; during this period, stir once every 5 minutes to avoid scorching and ensure that the pumpkin is boiled rotten;

[0044] 4) beating: the product obtained in step 3) is beaten with a beater, and is divided into the first slag discharge and the second slag discharge according to the mesh diameter, (wherein the first sieve mesh aperture is Φ1.2mm, and the second sieve mesh aperture is Φ0.6mm), the first slag is first passed th...

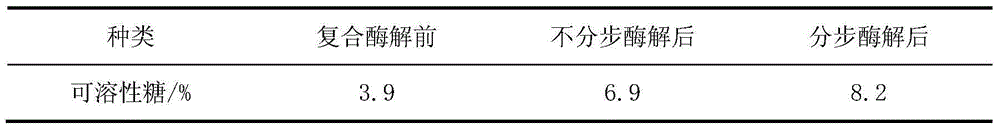

Embodiment 2

[0057] A preparation method of instant pumpkin powder, comprising the following steps:

[0058] 1) Pre-treatment: select fresh pumpkins that are half-ripe, remove spoiled and moldy pumpkins, clean the pumpkins, peel and remove seeds;

[0059] 2) crushing: the above-mentioned pumpkin after seed removal is crushed into pumpkin particles with a particle size of less than 1cm with a crusher;

[0060] 3) Cooking: Add 10% water of the crushed pumpkin granules to the above pumpkin granules, use a sandwich pot, and cook at a temperature of 95-100°C for 35 minutes; during this period, stir once every 5 minutes to avoid scorching and ensure that the pumpkin is boiled rotten;

[0061] 4) beating: the product obtained in step 3) is beaten with a beater, and is divided into the first slag discharge and the second slag discharge according to the mesh diameter, (wherein the first sieve mesh aperture is Φ1.2mm, and the second sieve mesh aperture is Φ0.6mm), the first slag is first passed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com