Antibacterial false tooth soft lining material and application thereof

A bacteriostatic and denture technology, applied in dental preparations, dental prostheses, compression molding cups, etc., can solve the problems of high cytotoxicity, concentration dependence, and easy drug resistance, and achieve good biocompatibility and strong The effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Formulation and preparation method

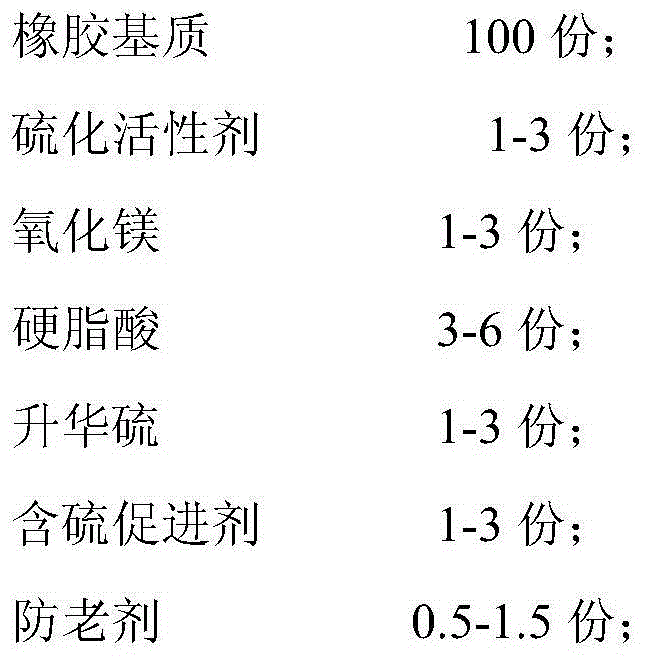

[0042] formula:

[0043]

[0044] Wherein, the rubber matrix is composed of eucommia gum and butadiene rubber, and the mass ratio of eucommia gum and butadiene rubber is: 10-90:90-10.

[0045] Preparation:

[0046] According to the proportion by weight, Eucommia ulmoides gum, butadiene rubber, vulcanization activator, magnesium oxide, stearic acid, and sulfur-containing accelerator were added in sequence, mixed evenly at 70°C-80°C, and then cooled, and waited for After cooling to room temperature, add sublimated sulfur and mix well; then stand for 22-26 hours, vulcanize at 140°C-160°C for 20-40 minutes to form, the vulcanization pressure is 9.5MPa-10.5MPa, and the material is released after curing.

[0047] 2. Materials and methods

[0048] 2.1 Main materials

[0049]

[0050] 2.2 Main equipment

[0051]

[0052]

[0053] 2.3 Extraction of eucommia gum

[0054] Using the petroleum ether-ethanol method, first cr...

Embodiment 2

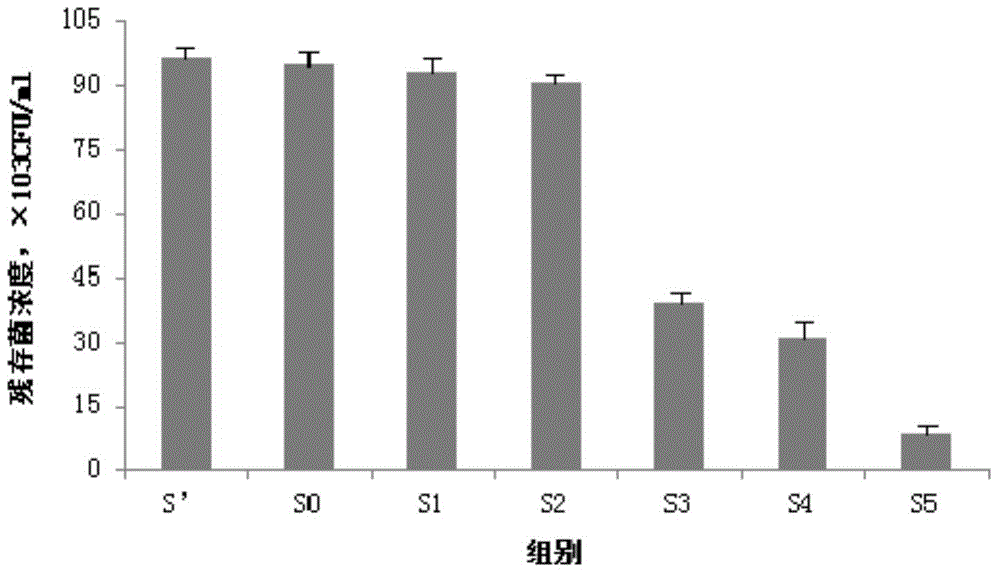

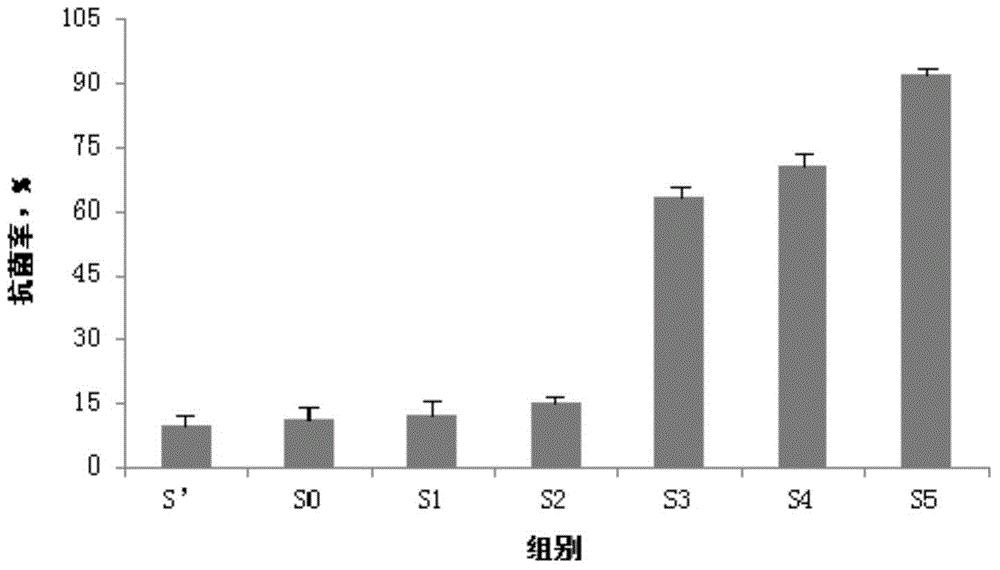

[0167] Embodiment 2 bacteriostasis test

[0168] 1. English abbreviation

[0169]

[0170] 2.1 Experimental materials

[0171] 2.1.1 Standard strains

[0172] Candida albicans CMCC (F) 98001, provided by China Microorganism Collection Management Center.

[0173] 2.1.2 Main experimental equipment and instruments

[0174]

[0175]

[0176] Water sandpaper of various particle sizes, glass test tube, sterilized tweezers, 250ml Erlenmeyer flask, inoculation loop, alcohol lamp

[0177] 2.1.3 Main experimental materials

[0178] 2.1.3.1 Eucommia gum composite material

[0179] The eucommia gum and butadiene rubber were softened several times on the double-roll mill at about 65°C according to the formula in the following table (Table 2-1), and then added sublimated sulfur, zinc oxide, magnesium oxide, stearic acid, Sulfur-containing accelerator CZ, anti-aging agent, fumed white carbon black, knead for a period of time, after the kneading is even, thin pass several times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com