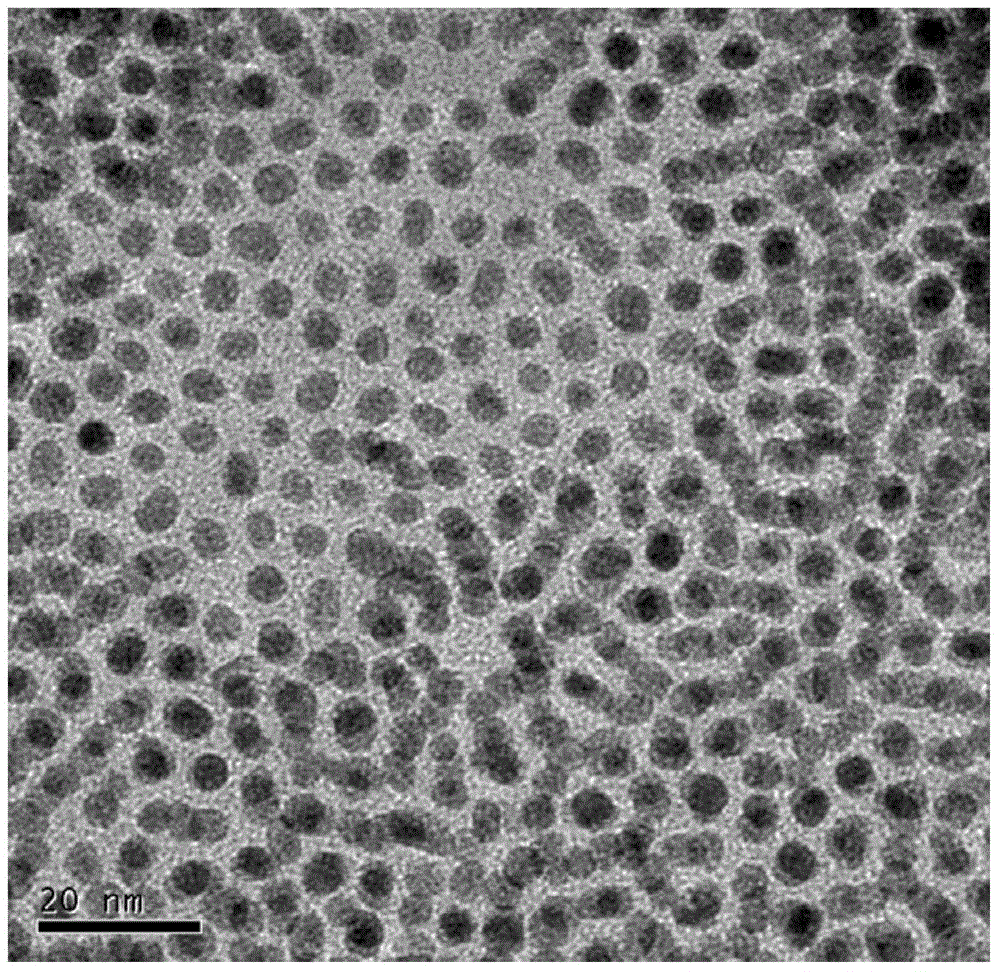

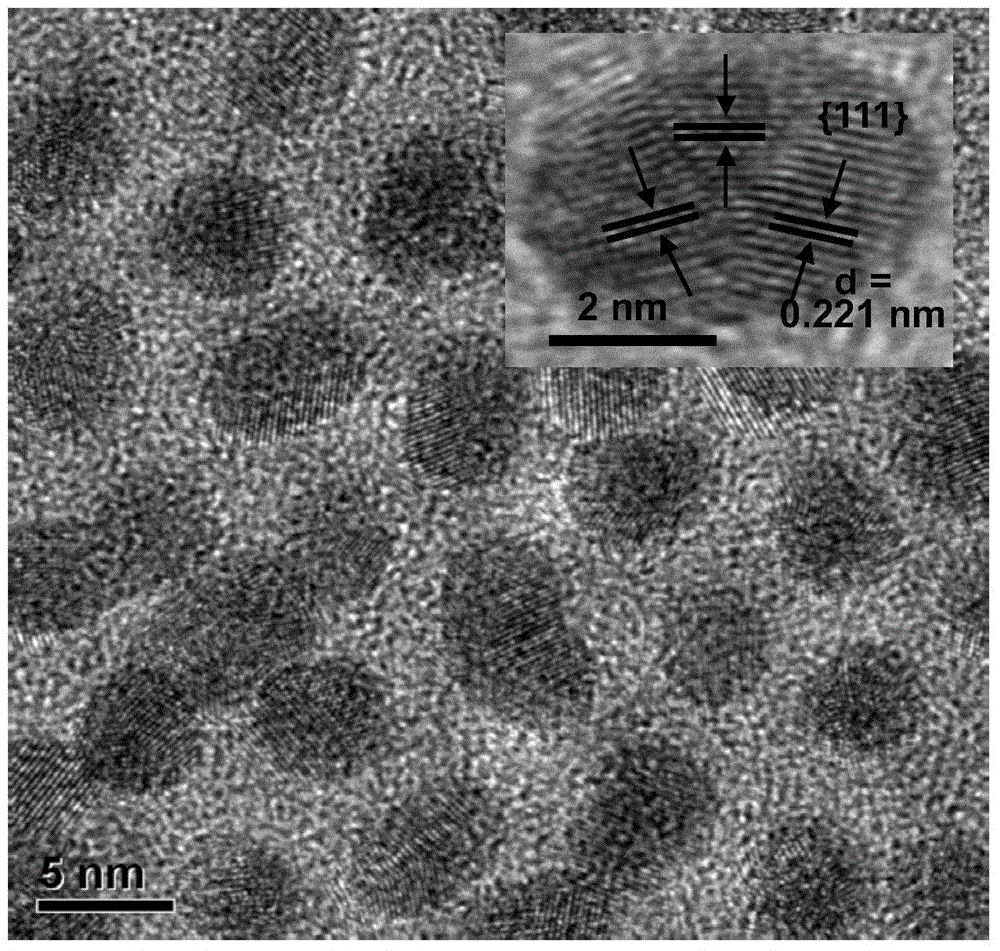

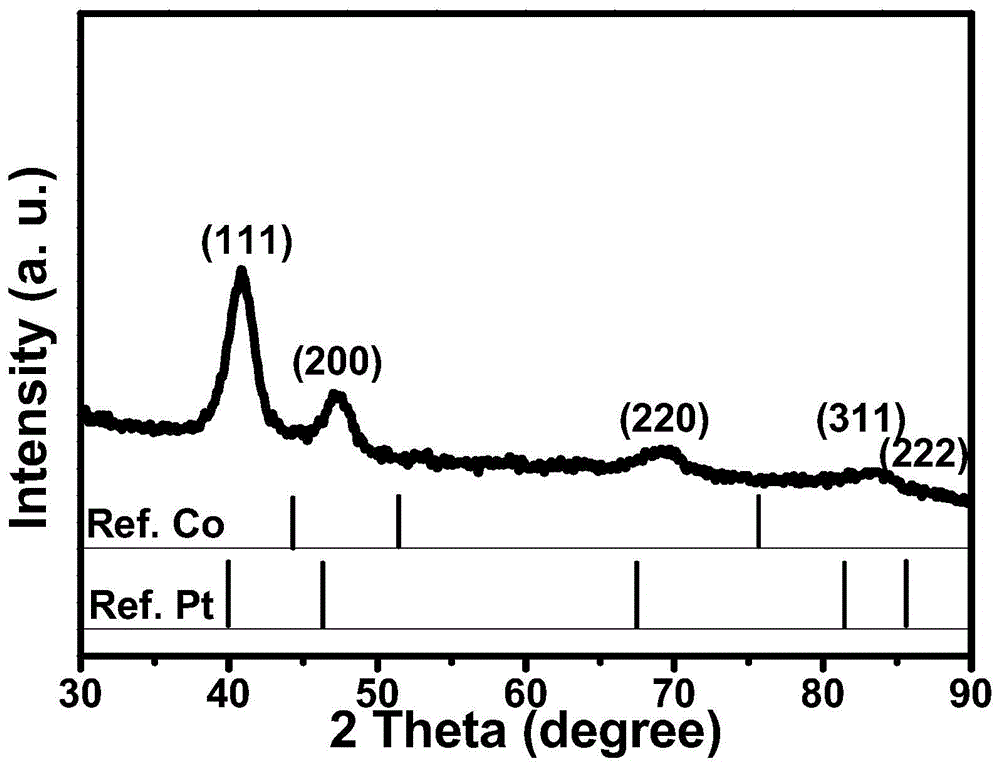

Platinum-cobalt nano-alloy mimic enzyme and preparing method and purpose thereof

A cobalt nanometer and enzyme-mimicking technology, which is applied in nanotechnology, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as single function, cumbersome preparation procedures, and high cost, and achieve high chemical efficiency. Good stability, repeatability, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] Implementation method: Dissolve chloroplatinic acid and cobalt acetate in ethylene glycol, add polyethylene glycol and aniline, stir well and place in a hydrothermal kettle, wherein the concentration of chloroplatinic acid is 0.001mol / L, and the concentration of cobalt acetate is 0.002 mol / L, the concentration of polyethylene glycol is 0.0025mol / L, and the concentration of aniline is 0.016mol / L. The reaction was heated at 150°C for 12h. After the reaction, cool down to room temperature, wash the reactant with acetone and ethanol, and centrifuge to remove the supernatant to obtain the platinum-cobalt nano-alloy.

Embodiment 3

[0048] Implementation method: Dissolve platinum acetylacetonate and cobalt chloride in benzyl alcohol, add polyvinylpyrrolidone and benzoic acid, stir well and place in a hydrothermal kettle, wherein the concentration of platinum acetylacetonate is 0.0005mol / L, and the concentration of cobalt chloride is 0.001mol / L, the concentration of polyvinylpyrrolidone is 0.00025mol / L, and the concentration of benzoic acid is 0.016mol / L. The reaction was heated at 200° C. for 1 h. After the reaction, cool down to room temperature, wash the reactant with acetone and ethanol, and centrifuge to remove the supernatant to obtain the platinum-cobalt nano-alloy.

Embodiment 4

[0050] Implementation method: Dissolve chloroplatinic acid and cobalt nitrate in diethylene glycol, add polyvinylpyrrolidone and benzaldehyde, stir well and place in a hydrothermal kettle, wherein the concentration of platinum acetylacetonate is 0.005mol / L, cobalt ketone nitrate The concentration is 0.01mol / L, the concentration of polyvinylpyrrolidone is 0.0025mol / L, and the concentration of benzaldehyde is 0.16mol / L. The reaction was heated at 120°C for 4h. After the reaction, cool down to room temperature, wash the reactant with acetone and ethanol, and centrifuge to remove the supernatant to obtain the platinum-cobalt nano-alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com