Aerosol-assisted synthesis method of Beta molecular sieve

An aerosol and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, etc., to achieve the effect of high utilization rate, simple synthesis process and reduced sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

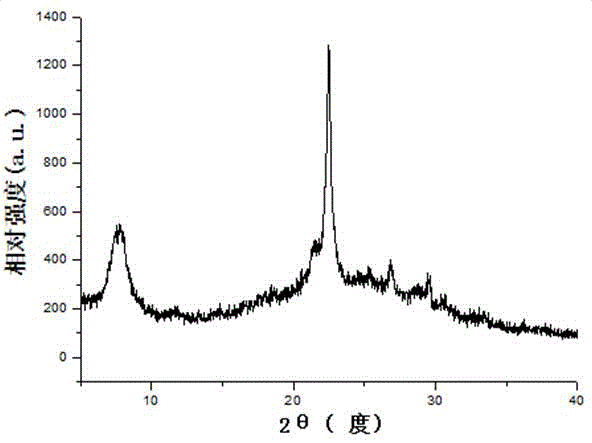

[0026] Mix 0.83g sodium metaaluminate, 20g silica sol, and 68.67g water and stir for 1 hour to form a mixed solution, in which SiO 2 : Al 2 o 3 : H 2 The O molar ratio is 1:0.033:38.15. Then an aerosol is formed by an aerosol generator, and silicon-aluminum oxide is obtained by drying. 0.8g of silicon-aluminum oxide is put into a 1.35ml stainless steel synthesis kettle with a polytetrafluoroethylene liner, and then 1.11g of a mass fraction of 25% is added. Aqueous solution of tetraethylammonium hydroxide, silicon aluminum oxide in SiO 2 The mol ratio with tetraethylammonium hydroxide is 1: 0.15, sealed at 145 DEG C and carry out crystallization reaction 72h, the gained solid product is washed with deionized water and then dried at 100 DEG C for more than 12 hours to obtain the final product Beta (Si / Al=30) Molecular sieve 0.72g, equivalent to 1L crystallization kettle can produce about 530g Beta molecular sieve. figure 1 For the XRD spectrum of this product, it can be se...

Embodiment 2

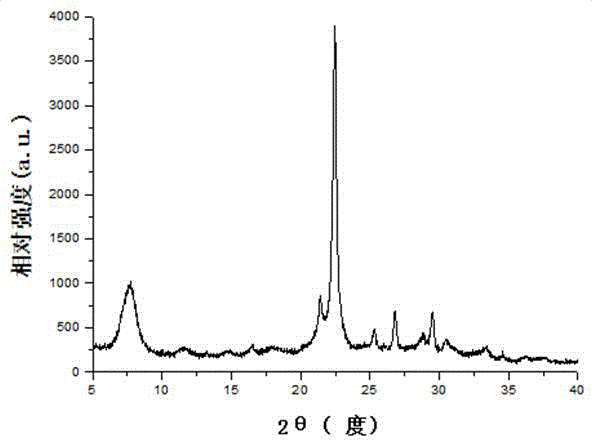

[0028] Mix 0.5g sodium metaaluminate, 20g silica sol, and 37.68g water and stir for 1 hour to form a mixed solution, in which SiO 2 : Al 2 o 3 : H 2 The O molar ratio is 1:0.02:28.7. Then an aerosol is formed by an aerosol generator, and silicon-aluminum oxide is obtained by drying. 0.8g of silicon-aluminum oxide is put into a stainless steel synthesis kettle with a polytetrafluoroethylene lining, and then 1.13g of 25% tetraethylene oxide is added. Aqueous ammonium hydroxide solution, SiO in silicon aluminum oxide 2 The mol ratio with tetraethylammonium hydroxide is 1: 0.15, sealed at 145 DEG C and carry out crystallization reaction 72h, the gained solid product is washed with deionized water and then dried at 100 DEG C for more than 12 hours to obtain the final product Beta (Si / Al=50) molecular sieve. figure 2 For the XRD spectrum of this product, it can be seen that there are 6 diffraction peaks at 2theta of 7.8°, 12.0°, 13.6°, 21.0°, 22.4°, and 29.4° on the XRD spect...

Embodiment 3

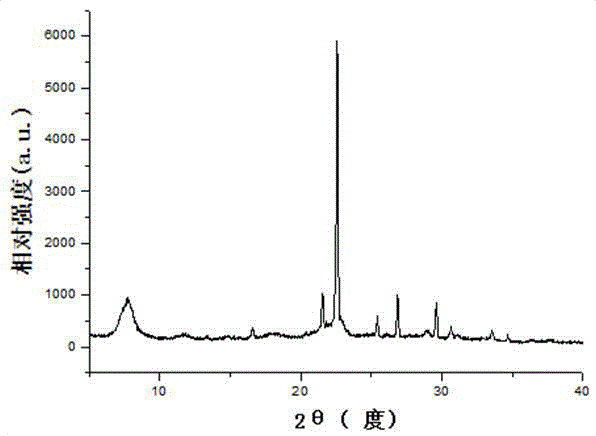

[0030] Mix 0.313g of sodium metaaluminate, 20g of silica sol, and 17g of water and stir for 1 hour to form a mixed solution, in which SiO 2 : Al 2 o 3 : H 2 The O molar ratio is 1:0.0125:9.4. Then an aerosol is formed by an aerosol generator, and silicon-aluminum oxide is obtained by drying. 0.8g of silicon-aluminum oxide is put into a stainless steel synthesis kettle with a polytetrafluoroethylene lining, and then 1.15g of 25% tetraethylene oxide is added. Aqueous ammonium hydroxide solution, SiO in silicon aluminum oxide 2 The mol ratio with tetraethylammonium hydroxide is 1: 0.15, sealed at 145 DEG C and carry out crystallization reaction 72h, the gained solid product is washed with deionized water and then dried at 100 DEG C for more than 12 hours to obtain the final product Beta (Si / Al=80) molecular sieve. Figure 4For the XRD spectrum of this product, it can be seen that there are 6 diffraction peaks at 2theta of 7.8°, 12.0°, 13.6°, 21.0°, 22.4°, and 29.4° on the X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com