Upwelling bipolar three-dimensional electrochemical reactor

A chemical reactor and bipolar technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor wastewater treatment effect, low current efficiency of three-dimensional electrochemical reactor, etc. problem, achieve the effect of increasing the volume, good water outlet effect, and avoiding the deposition of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

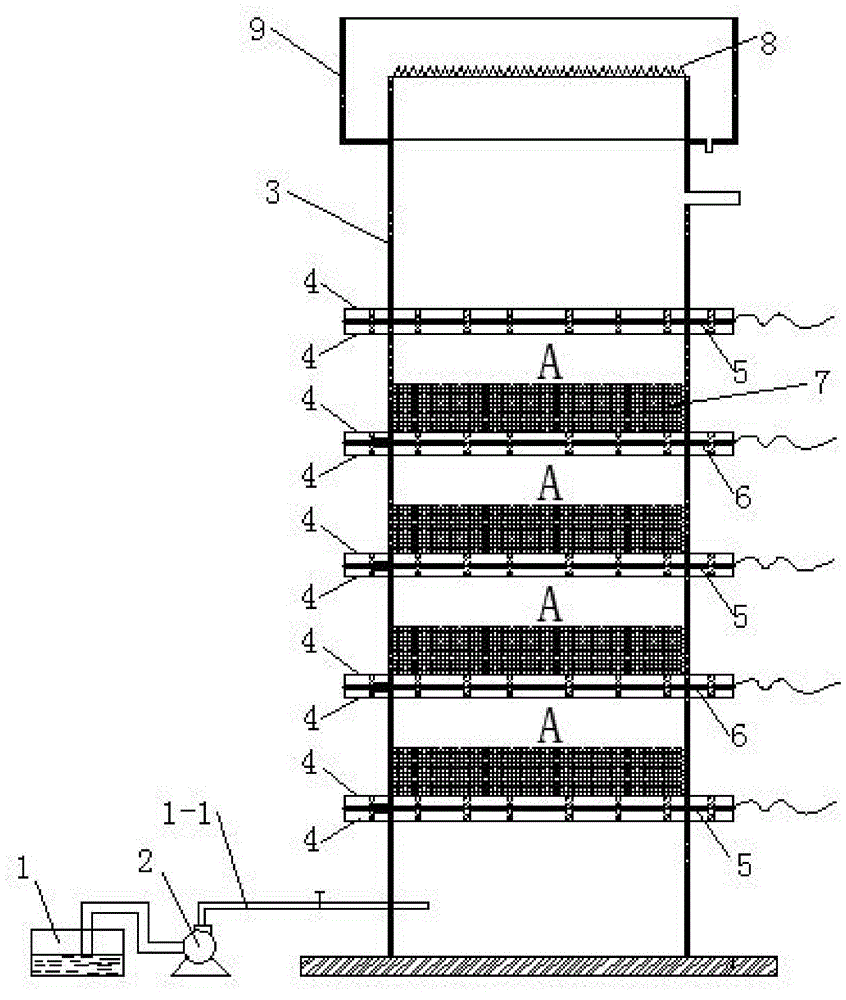

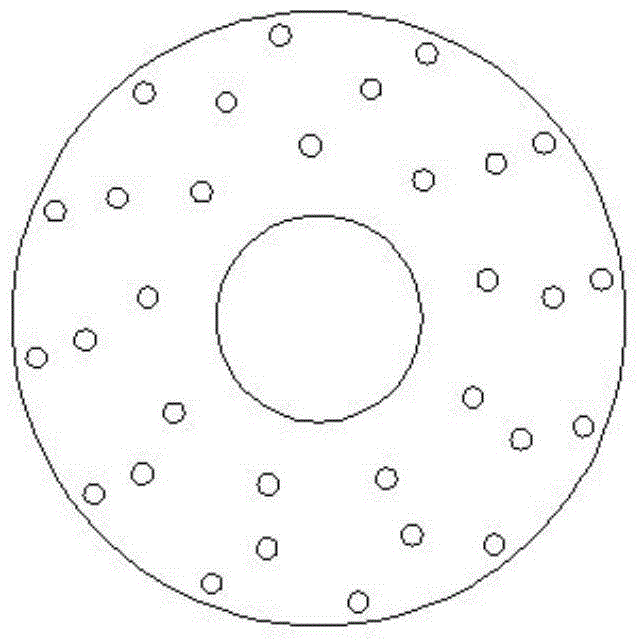

[0012] Specific embodiment one: the upflow bipolar three-dimensional electrochemical reactor of this embodiment comprises working electrode cathode 5, working electrode anode 6, plexiglass screen 4, particle electrode 7 and overflow weir 8, in two layers of plexiglass sieve The working electrode cathode 5 is sandwiched between the nets 4 to form a cathode assembly, and the working electrode anode 6 is sandwiched between two layers of plexiglass screens 4 to form an anode assembly, and water holes are evenly opened on the working electrode cathode 5 and the working electrode anode 6 , a plurality of sets of cathode assemblies and anode assemblies are alternately arranged at intervals along the vertical direction of the cylindrical reactor body 3, a reaction unit A is formed between adjacent cathode assemblies and anode assemblies, and each reaction unit A is filled with particles The electrode 7 and the overflow weir 8 are arranged on the top of the cylindrical reactor body 3 , ...

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the anode assembly is formed by fixing two layers of plexiglass screen 4 and the working electrode anode 6 through the flange, and the two layers of plexiglass screen 4 and the working electrode are fixed by the flange The cathode 5 forms a cathode assembly.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the working electrode cathode 5 is a titanium plate electrode, a stainless steel electrode or a graphite plate electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com