Preparation method of low-resistance and high-selectivity mixed matrix membrane based on hollow MOFs material

A mixed-matrix membrane and high-selectivity technology, applied in the field of membrane separation, can solve problems such as easy-to-produce defects, selectivity reduction, and large gas transmission resistance, so as to increase gas permeation rate, reduce mass transfer distance, and reduce mass transfer The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

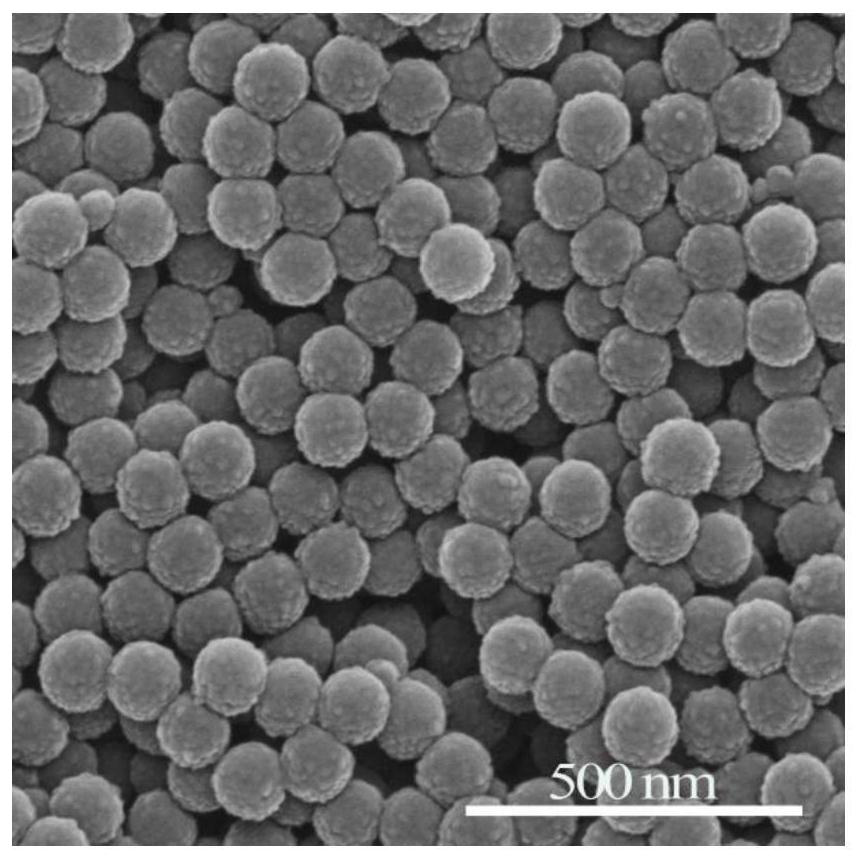

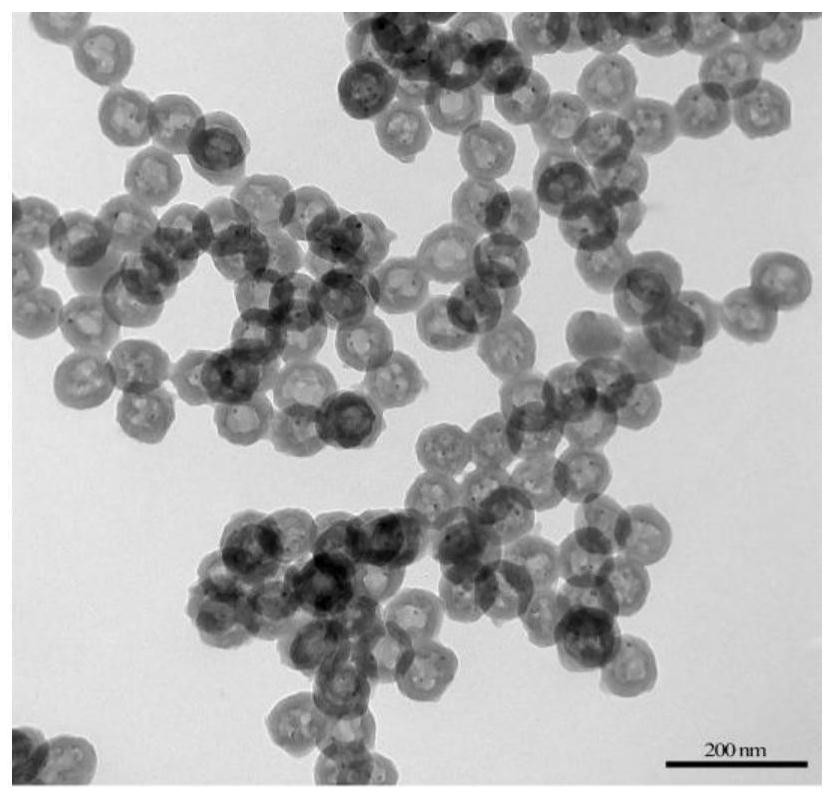

[0029] Preparation of nano-sized hollow ZIF-8: Weigh 120mg of zinc nitrate hexahydrate and 66.4mg of 2-methylimidazole and dissolve them in 32ml of methanol, mix them after stirring and dissolving, then add 176mg of polystyrene to it, and ultrasonically 5min, react in a water bath at 70°C for 30min, cool to room temperature after the reaction, rinse with deionized water and absolute ethanol 5 times alternately, then dissolve the product in DMF, etch for 48h, and wash by centrifugation to obtain the desired polystyrene-modified hollow MOFs microsphere materials.

[0030] Preparation of Pebax solution: Weigh 3.09g of Pebax-1657 particles and add it to 100g of ethanol / water (70 / 30) mixed solution, condense and reflux at 80°C for 4 hours, and transfer the solution to a container for later use after cooling naturally.

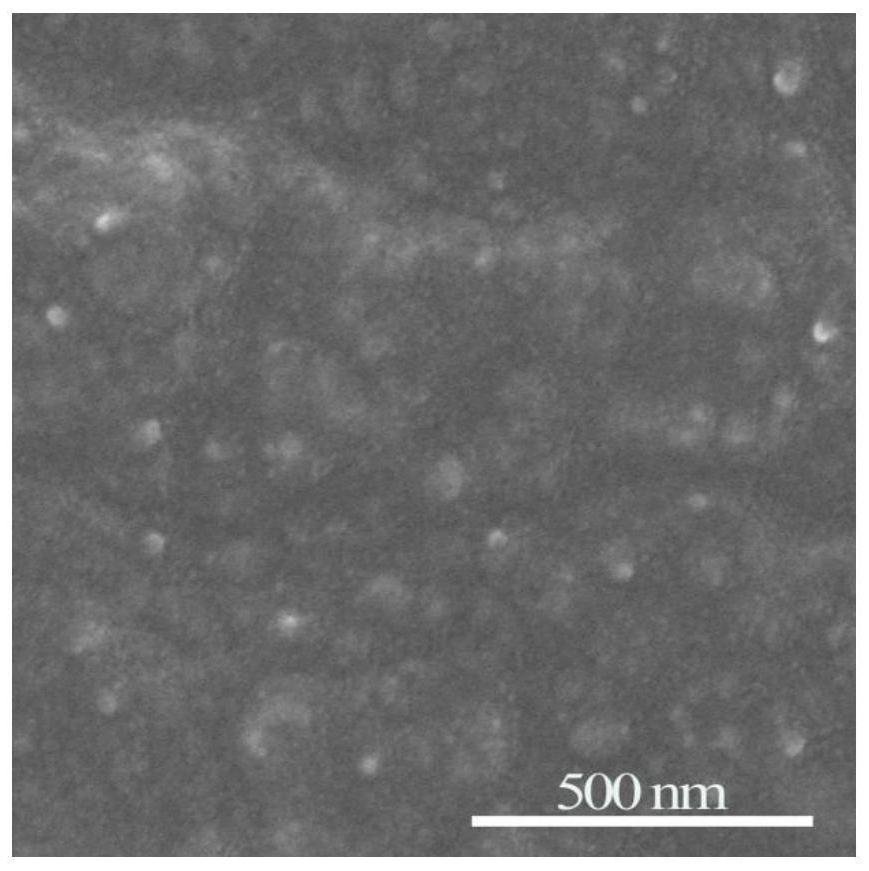

[0031] Preparation of mixed matrix membrane: Add hollow MOFs microsphere material with a mass percentage of 5%, 10% or 15% to 8g Pebax-1657 solution, stir for 1h an...

Embodiment 2

[0033] Tests have shown that the low-resistance and high-selectivity mixed matrix membrane based on hollow MOFs prepared in this example, under the test conditions of 25 ° C and 0.1 MPa, CO 2 The permeability coefficient can reach 172.4Barrer, CO 2 / N 2 The selectivity was 87.9.

[0034] The hollow MOFs microsphere material of the present invention achieves polystyrene modification while preparing the hollow structure, and has the advantages of simple synthesis steps, and the polystyrene on the surface can make the hollow MOFs microsphere material and the matrix better compatible properties, prepare defect-free mixed matrix membranes, and obtain high gas selectivity; the hollow structure can reduce the mass transfer resistance of the membrane and increase the gas permeability of the membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com